Description

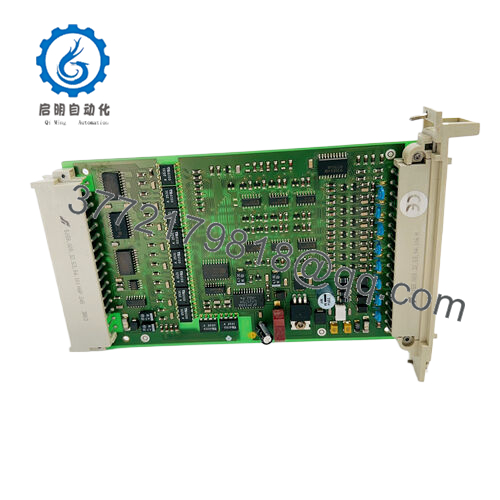

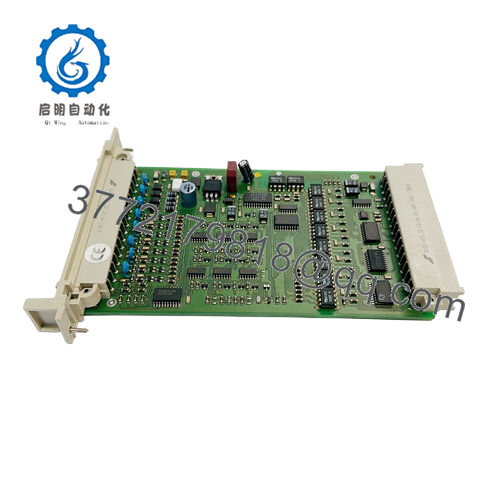

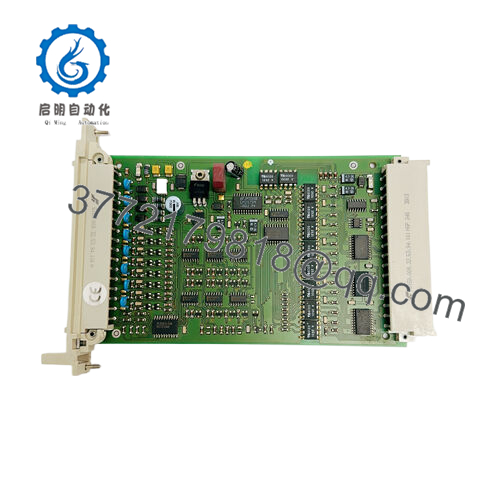

HIMA F3237 984323702 is an 8-channel safety related input module that serves as a critical link between field sensors and control systems in industrial automation architecture.

F3237 984323702

It adopts a redundant, security related processor system that allows for comprehensive self checking directly on the module. This means that during operation, it will continuously verify its integrity, thereby reducing the risk of undetected failures. The main self-test program includes checking for crosstalk between eight input channels and the functionality of input filters. In terms of signal detection, it follows strict standards: the 0 signal is recognized within the range of 0.35 ≤ ie ≤ 1.2 mA, while the 1 signal is recognized within the range of 2.1 ≤ ie ≤ 6.0 mA. This module also requires a line impedance of ≤ 50 ohms (in accordance with DIN 19234 standard). In terms of wiring, it is recommended to use shielded cables for on-site input circuits, while twisted pair cables can further improve performance. However, in interference free and short distance scenarios, such as inside well shielded cabinets, unshielded and non twisted pair cables can be used. However, it is worth noting that shielded cables are the best choice for achieving optimal anti-interference performance of analog inputs.

F3237 984323702

Technical specifications:

Model: F3237 984323702

Brand: HIMA

Type: 8-channel input module related to safety

Input voltage: 24 VDC

Working temperature range: -40 ° C to 70 ° C

Interface/Bus: Profibus, Modbus (if applicable)

Compliance: CE, RoHS, IEC 61508 SIL 3

Supported protocols: Profibus DP, Modbus TCP

Contact Us

Phone:+86 16626708626

WhatsApp/WeChat:+86 16626708626

Email: 3772179818@qq.com

F3237 984323702

Main features and advantages:

This module has been designed with full consideration for safety and reliability, meeting the strict requirements of IEC 61508 SIL 3, ensuring reliability in high-risk industrial applications. Its redundant processor system and continuous self checking capability reduce the possibility of unexpected failures, providing long-term performance stability. The compatibility with various industrial protocols and standard wiring requirements of this module simplify integration with existing control systems, reducing engineering costs. Engineers can quickly install and debug F3237 984323702 without spending too much time customizing interfaces and wiring settings. The built-in diagnostic function makes proactive maintenance possible. By continuously monitoring input signals and the internal status of modules, potential problems can be detected early, allowing for timely intervention and reducing unplanned downtime. This not only improves the overall productivity of industrial processes, but also reduces maintenance costs caused by major malfunctions.

F3237 984323702

Application areas:

In oil and gas refineries, it is used to connect safety related proximity switches to ensure immediate detection of any abnormal conditions, such as unwanted objects near critical equipment. The ability of this module to accurately process these switch signals helps prevent accidents and protect the safety of personnel and valuable assets.

In power plants, it plays a critical role in monitoring various sensors that provide data about the health status of equipment, such as temperature sensors on generators or vibration sensors on turbines. By accurately transmitting this information to the control system,F3237 984323702enables operators to take timely action to maintain optimal power generation and prevent equipment failures.

In chemical processing facilities, strict safety measures are required for handling hazardous substances, and this module is used to interface with sensors that detect leaks, pressure changes, or temperature fluctuations. Its reliable signal processing capability is crucial for triggering safe shutdown or corrective measures to prevent chemical leaks and other hazardous situations from occurring.

F3237 984323702

Related products:

HIMA F3238: With additional input channels or enhanced processing speed, it is suitable for more complex industrial applications that require processing more safety related input signals.

HIMA F3237-EX: Designed specifically for hazardous areas with explosive atmosphere risks. This version provides an additional layer of security to ensure reliable operation in environments where standard modules may pose security risks.

HIMA F3236: Slightly reduced feature set, suitable for small industrial settings or applications that do not require all the functions of F3237 984323702.

HIMA F3237-R: Redundant configuration module provides higher reliability for critical mission applications. If a component in a module fails, the redundant system can seamlessly take over, ensuring continuous operation and maintaining safety integrity.

HIMA F3237-PRO: Equipped with advanced diagnostic and communication capabilities. This version is customized for complex industrial environments that require in-depth monitoring and precise control, allowing for more detailed analysis of input signals and better integration with other advanced control systems.

HIMA F3237-LITE: Very suitable for installations with limited space, where size and weight are important considerations. Despite its smaller size, it still retains the basic safety and signal processing functions of standard F3237 984323702.

Installation and maintenance:

Before installing HIMAF3237 984323702, several important pre installation checks need to be performed. Firstly, carefully verify whether the communication protocol and signal requirements of your existing control system are compatible with F3237 984323702 Ensure that the power supply at the installation site meets the voltage and current requirements of the module. Check the available installation space, especially if it is a DIN rail or other standard industrial installation, to ensure proper installation, while considering the size of the module. In addition, confirm that the environmental temperature, humidity, and other environmental conditions at the installation location are within the operating range specified by the module.

For continuous maintenance, regularly check the diagnostic information provided by the module. Pay close attention to any status indicator lights or fault messages that may be displayed. Regularly inspect wiring connections for signs of wear, corrosion, or looseness. Conduct a comprehensive functional test once a year to ensure that all input channels are functioning properly, the self checking mechanism operates as expected, and the module maintains its high performance and safety integrity.

HIMA Other Product Models:

HIMA PS1000WR011

HIMA F3DIO20/802 982200484

Hima F8621A

HIMA F8627X 984862765

HIMA 80105 984080105

HIMA ELOP II V5.5

HIMA 80105 984080105

HIMA X-SB01 985210207

HIMA F8628X

HIMA F8650X 984865065

HIMA A1-dig 984200004

HIMA X-AI3201 985210213

HIMA TRIX F35 982200416

HIMA F3DIO20/802 982200442

HIMA F8650E

HIMA F3226A

HIMA F8621A 984862160

HIMA F-PWR01

HIMA F3DIO16/801

HIMA Z7130

HIMA F3240

HIMA F30 03 SILworX 20/9

HIMA F3237

HIMA F8651X

HIMA F3DIO20/802 982200404

HiMA F35 030 34 SILworX

HIMA F-COM01

HIMA F-IOP01

HIMA F30 F30 010 20 OS-REV.V6.46/V11.28

HIMA F30 F30 010 20 OS-REV.V6.46/V11.28

WhatsApp: +86 16626708626

WhatsApp: +86 16626708626 Email: 3772179818@qq.com

Email: 3772179818@qq.com Phone: +86 16626708626

Phone: +86 16626708626