Description

In the intricate machinery of industrial automation, where turbine and compressor shafts spin under immense centrifugal forces, the undetected buildup of relative vibrations can spell disaster—from bearing journals scoring against housings to orbital whirls that cascade into rub failures, compromising process control integrity and inviting catastrophic downtime. Picture a high-pressure gas compressor in a fertilizer plant, where thermal gradients subtly shift rotor-stator clearances, amplifying displacements that evade coarse accelerometers and trigger unneeded shutdowns or overlooked threats, eroding compliance with API 670 standards. Or in a steam turbine drive for a paper machine, where misalignment from foundation settling masks phase-specific anomalies, leading to seal flushes or blade fatigue that inflate repair bills and production gaps. These are the stealthy stressors in rotordynamic environments, where high reliability demands precise relative motion tracking to preserve I/O signals from proximity probes, yet conventional monitors often aggregate data indiscriminately, fostering false positives or blind spots that burden engineers with over-tuned filters or multi-probe sprawls. Without targeted differential analysis, scaling predictive health programs becomes a quagmire of data overload, turning vibration guardians into guesswork gambles.

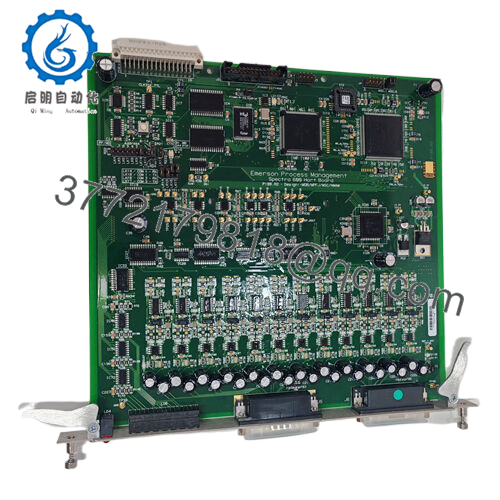

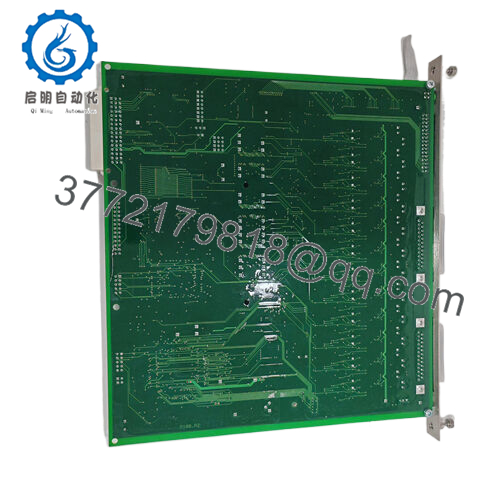

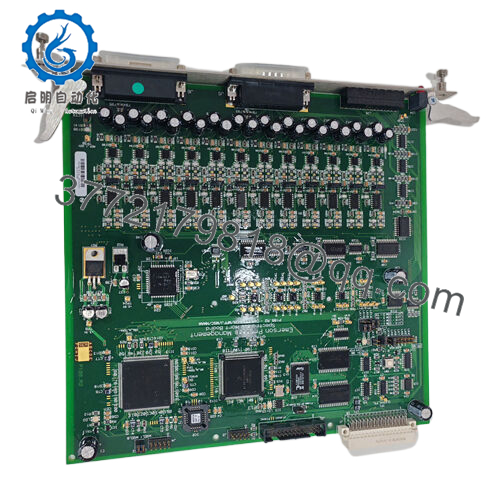

This is the displacement discernment deficit the Emerson P188.R2 confronts as a Shaft Relative Vibration Monitor in the legacy Ovation machinery protection suite, calibrated to quantify peak-to-peak excursions with surgical acuity for safeguarding critical rotating assets. In demanding installations like petrochemical cracking units or utility boiler feed pumps, it proves pivotal during asset expansions, where elevated speeds and variable loads outpace generic seismics; without it, operators navigate lumped spectra that obscure journal threats or necessitate auxiliary voting to meet SIL 2 thresholds. The Emerson P188.R2 slots into Ovation controller racks, conditioning dual eddy-current channels to resolve motions down to 0.1 mil, with configurable alarms—direct, reverse, and radial—that cascade to ESD logic via dry contacts. Its firmware revision 2 enhances bandpass adaptability (2-1000 Hz), buffering orbits for post-event dissection, ensuring I/O signal resilience amid electrical transients.

For protection specialists evaluating legacy upgrades, the Emerson P188.R2 clarifies crossroads: it optimizes rack utilization with 1-slot modularity, tunable through Ovation Developer Studio for custom envelopes, and its -20°C to +70°C span eases retrofit in legacy enclosures. In vibration-vexed operations where incidents tally millions in lost steam, this monitor’s phase demodulation preempts rub precursors, reshaping relative risks into refined responses. Whether fortifying a multistage expander’s thrust line or arraying across a generator train, the Emerson P188.R2 reinforces your framework with modular integration that bolsters process control, interweaving exacting extraction with enduring alarming to weather whirling woes.

- P188.R2

- P188.R2

Embedded within the Ovation controller’s protection layer, the Emerson P188.R2 serves as the astute arbiter of shaft-housing dynamics, rack-mounting into a single slot where it harnesses 24 VDC rails to precondition probe signals via integrated amplifiers, deriving differential vectors for real-time thresholding. It couples through the system’s backplane, accepting orthogonal X-Y non-contact inputs (typically -80 to +80 mV/mil) to compute not-1x filtered displacements, then relays enveloped data downstream to the host CPU or DeltaV hybrids via Modbus RTU. In the I/O schema, it resides upstream from radial mounts—often API-compliant brackets—and downstream of rack fusion, where resolved peaks (up to 50 mil pk-pk) inform de-energize-to-trip via redundant relays, enabling 2oo3 voting for fault-tolerant SIL 2.

Its fielding flows with seasoned subtlety: no exotic adapters, as Bently-style connectors enable swaps from 3300 series, while DSP cores excise line frequency for baseline purity, signaling via front LEDs on 20% threshold breaches. For a boiler circulator’s coupling guard, the Emerson P188.R2 discriminates forward/reverse orbits at 1800 RPM, archiving 512-point vectors for AMS integration; self-checks detect probe shorts through heartbeat pulses. This station amplifies the stack’s sophistication—pair with P140 thrust monitors for axial fusion, or network via Ethernet for fleet-wide trending—while varnished boards repel 90% RH in turbine bays. The Emerson P188.R2 thereby weaves into your rotordynamic web as a perceptive parser, where displacements disclose with deliberate grace, and vectors validate vigilance rather than vagueness.

| Specification | Details |

|---|---|

| Model Number | P188.R2 |

| Brand | Emerson |

| Type | Shaft Relative Vibration Monitor |

| Input Voltage | 18-32 VDC |

| Operating Temp Range | -20°C to +70°C |

| Mounting Style | Rackmount (1-slot) |

| Dimensions | 10 x 1.5 x 7 in (254 x 38 x 178 mm) |

| Weight | 2 lbs (0.9 kg) |

| Interface/Bus | Ovation Backplane, Modbus RTU |

| Compliance | API 670, IEC 61508 SIL 2, CE, RoHS |

| Supported Protocols | Modbus RTU, OPC (via host) |

| Typical Power Draw | 6 W |

Incorporating the Emerson P188.R2 lays a reliability foundation where orthogonal filtering discriminates rubs from resonances, allowing shafts to sustain 3600 RPM envelopes with 0.2 mil precision amid load lurches—your trains evade the alarm avalanches that once obscured origins, all while probe isolation thwarts EMI from nearby generators. In thermal-turbulent housings, its damped amplifiers preserve displacement fidelity that could otherwise warp under casing vibes, engineered to outlive 20-year amortizations without span shifts.

The curation cadence leans to clairvoyance, as vector logs and alert latches unearth gap variances via Ovation streams, spotlighting a radial bias in buffers before escalation—slashing MTTR from disassembly delves to data dives and lightening engineering for phase forecasts over fault frays. Tailored for the tenacity of nonstop rotations, it pledges perennial poise through shock-hardened pins that endure 3 g spectra, boosting MTBF past 150,000 hours while trimming spares to amplifier boards. For evolving ensembles, the Emerson P188.R2‘s Ovation perch quickens monitor infusions, circumventing reconfiguration rigors, emancipating scopes for ML-modeled motion maps.

Widen the window, and its Modbus marrow marshals metrics to health hubs, linking relative renders with lube logs to prefigure pad perils. Wardens wield with warranted wisdom, as envelope excesses emerge as explicit emblems, truncating triage trails in orbit obscurities. Opting for the Emerson P188.R2 instills a monitor that muses motions, fusing finicky filtering with fortified fortitude to propel your industrial automation from symptomatic to sovereign.

In syngas reformers, the Emerson P188.R2 tracks expander journals amid syngas surges and catalyst chills, where eccentricity endangers seals—its pk-pk peaks preserve critical system uptime, demodulating orbits in process control environments to forestall flushes without flow forfeits.

Nuclear coolant pumps embed it for impeller feedbacks, braving radiation proxies and flow fluxes; under these harsh conditions, the Emerson P188.R2‘s SIL 2 scaffolding yields high reliability, voting vectors for flawless circulations in fast data cycles across reactor loops.

Amid fiberglass winders, it aggregates mandrel displacements from tension sensors, with RoHS rapport suiting resin refits—channel acuity enables sparse skids, curtailing clutter in regulated process control environments. These theaters tout the Emerson P188.R2‘s prowess for rotordynamic rangers routing against ripples.

P188.R1 – Firmware predecessor with baseline bandpass for legacy Ovation retrofits

P140 – Thrust Position Monitor companion for axial integration in compressor trains

P190 – Acceleration Variant for broadband case vibes pairing with P188.R2 relatives

3500/42M – Bently Nevada 4-channel alternative for hybrid vibration suites with P188.R2

A6110 – AMS 6500 successor module with enhanced FFT for upgrading P188.R2 installs

PR6424/004-000 – Proximity probe kit tailored for P188.R2 eddy inputs

Ovation 5X00 – Controller chassis hub housing P188.R2 in full machinery protection arrays

PR9373/010-010 – Velocity sensor add-on for enveloped inputs feeding P188.R2 trends

Before rack-riveting the Emerson P188.R2 into your Ovation frame, benchmark probe linearity—post-API 670 ensures 10% span fidelity, per Emerson’s calibration codex, so a shaker table skim unmasks offsets. Appraise chassis circulation; in >60% slotted shelves, mandate 12 CFM blowers to peg amplifiers under 70°C, and probe DC lines for <40 mV hum—teaming a ferrite choke nips EMI echoes. Scrutinize ribbon edges for continuity sans shorts, as faint bridges can bias phases from fit.

In the fray, trimonthly Modbus trawls for pk-pk variances past 5% tandem with rack LEDs for orbital oneness. Biannually, cue internal proofs via Developer—replicate a 0.5 mil whirl to time relay snap below 50 ms—and retorque backplane pins to 0.4 Nm, alert to warp in thermal tides. For vapor-varnished vaults, annual varnish views via endoscope hunt for cracks early, synced with vector vaults for baseline bars. These paces pace into asset audits, perpetuating the Emerson P188.R2‘s perspicacity sans prodigal pulls.

WhatsApp: +86 16626708626

WhatsApp: +86 16626708626 Email:

Email:  Phone: +86 16626708626

Phone: +86 16626708626