Description

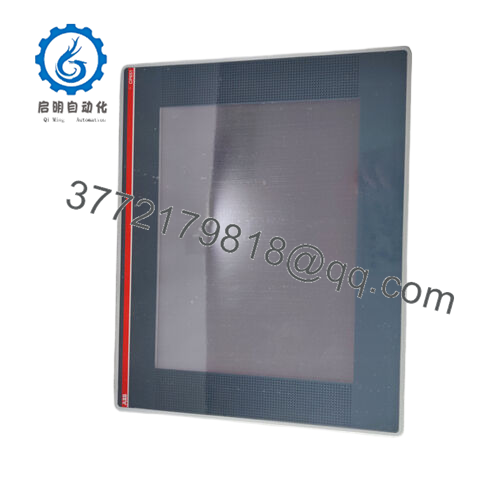

CP651-WEB Product Introduction:

CP651-WEB is a network-based communication gateway designed to be easily integrated into existing industrial automation systems. It serves as a central hub, connecting various field devices including programmable logic controllers (PLCs), human-machine interfaces (HMIs), and smart sensors to enterprise networks and cloud based platforms. By utilizing standard Ethernet interfaces and industry mature protocols such as Modbus TCP and OPC UA, this device is able to achieve seamless data exchange between different components of the automation stack.

CP651-WEB

This gateway supports advanced remote management features, allowing users to access and control connected devices through a web browser. Its built-in web server provides an intuitive interface for monitoring real-time data, configuring device parameters, and generating reports. CP651-WEB also provides secure communication channels to protect sensitive industrial data from unauthorized access. In terms of system integration, due to its compatibility with various control platforms and backplane architectures, it can be easily deployed in new installations and legacy systems. Whether as part of a small local network or a large distributed automation system, CP651-WEB plays a crucial role in achieving remote monitoring and control, enhancing the overall flexibility and responsiveness of the system.

CP651-WEB

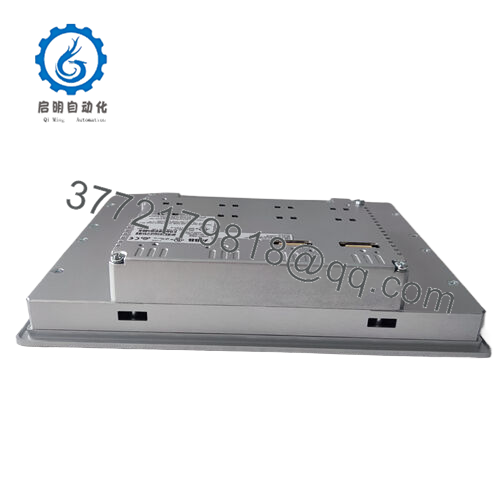

Technical specifications:

Model: CP651-WEB

Brand: ABB

Type: Network based communication gateway

Input voltage: 100-240 VAC

Working temperature range: -20 ° C to 60 ° C

Installation method: DIN rail or panel installation

Size: 120mm x 80mm x 40mm

Weight: 0.3 kg

Interface/Bus: Ethernet (10/100 Mbps), RS-232/485

Compliance: CE, FCC, RoHS

Supported protocols: Modbus TCP, Modbus RTU, OPC UA, MQTT

Typical power consumption: 8 W

Contact Us

Mobile:+86 16626708626

WeChat/WhatsApp:+86 16626708626

Email: 3772179818@qq.com

CP651-WEB

Main features and advantages:

It is designed to be reliable and easy to use, ensuring continuous performance and reducing the need for frequent manual intervention and expensive on-site visits. Its remote monitoring function enables operators to proactively identify potential issues, achieve timely maintenance, and minimize unplanned downtime. This translates into significant cost savings, as production losses caused by unexpected failures are greatly reduced.

The seamless integration of this product with existing systems reduces engineering costs. With support for multiple protocols and standard interfaces, it can be quickly integrated into various automation settings, accelerating project progress. The intuitive web-based interface simplifies device management, allowing experienced engineers and novice operators to efficiently monitor and control connected devices even for complex networks. In addition, the secure communication function of CP651-WEB protects industrial data, ensuring the integrity and confidentiality of critical information. Overall, this communication gateway provides industrial automation professionals with higher operational efficiency, improved productivity, and greater peace of mind.

CP651-WEB

Application areas:

CP651-WEB has been widely used in various industries. In the manufacturing industry, it is used to remotely monitor production lines of different facilities, ensuring smooth operation and responding quickly to any abnormal situations. For example, in an automotive assembly plant, a gateway can connect all PLCs that control robotic arms, conveyors, and quality control systems, allowing engineers in the central control room or even off-site to monitor performance, adjust settings, and troubleshoot in real-time.

In the field of energy, especially in power plants and wind farms, CP651-WEB enables remote monitoring of generators, turbines, and other critical equipment. Operators can access real-time data on power output, equipment health status, and environmental conditions anytime and anywhere, promoting proactive maintenance and optimizing energy production. In addition, in smart city infrastructure projects, this device plays a critical role in managing and monitoring distributed systems such as water treatment plants, traffic control networks, and building automation systems. Its ability to provide remote access and real-time insights makes it an ideal choice for applications that require continuous operation and efficient management.

CP651-WEB

Related products:

CP652-WEB: With higher processing power and support for more simultaneous connections, it is suitable for large-scale, high demand applications.

CP650-LITE: With basic remote monitoring capabilities and limited protocol support, it is suitable for small projects or simple automation settings.

CP651-PRO:, Designed specifically for harsh and critical environments, it features enhanced safety features, redundant power supplies, and an expanded temperature range.

CP651-MQTT: Can seamlessly integrate with IoT platforms and cloud based analytics services.

CP651-RS485: a variant focused on RS-485 communication, providing extended connection options for devices using this serial interface.

CP651-EDGE: allows for local data processing and analysis, reducing reliance on cloud infrastructure and improving response time.

Installation and maintenance:

Before installing CP651-WEB, it is essential to verify network compatibility. Ensure that the network infrastructure supports the required Ethernet speed and has sufficient bandwidth to handle the data traffic generated by connected devices. Check IP address settings and subnet configurations to avoid conflicts within the network. In addition, confirm that the power supply meets the requirements of the equipment, as unstable power supply may cause unstable operation.

For daily maintenance, the status indicator lights of the equipment should be regularly monitored, as they provide valuable information about the health status of the equipment operation. Check for any error messages or abnormal flashing patterns that may indicate a problem. Regularly update the firmware of the device to benefit from the latest security patches, performance improvements, and protocol enhancements. In addition, check network connections and cables to ensure a secure and reliable connection. Regularly backup the configuration settings of the device to prevent data loss caused by unexpected failures. By following these maintenance practices, you can ensure that CP651-WEB continues to operate reliably and efficiently in your industrial automation system.

Other ABB product models:

ABB unitrol1000-7 3BHE016011R0006

ABB UNITROL1010 3BHE035301R1002

ABB UNITROL1010-0410

ABB UNITROL1020 3BHE030579R0006

ABB UNITROL1020 UNS0119A-Z,V1 3BHE030579R000

ABB XUD194 XUD194A 3BHC018137R0001

ABB XV5628A

ABB Y129740-002

ABB YPI105C

ABB YPK112A 3ASD573001A13

ABB YPO104

ABB YPP-105F(YT204001)

ABB YPP110

ABB YPQ110A

ABB YPQ110A 3ASD573001A5

ABB С-093H

ABB PCD231

ABB HIEE300661R0001 UPC090AE01

ABB FMT200-ECO2

ABB 3BHB040253R0001

ABB SC520M 3BSE016237R1

ABB REC670 1MRK004814-AG

ABB TGM5 P14436-1072510

ABB GOP2000

ABB GOP2010

ABB 3BHE030579R0003

ABB 1SVR040000R1700

ABB DCF506-0140-51-0000000

ABB PCD530

ABB 1TGE120016R0104

ABB 1MRK000614-AB

ABB 5SHY35L4510

ABB PYT0450W071A

WhatsApp: +86 16626708626

WhatsApp: +86 16626708626 Email: 3772179818@qq.com

Email: 3772179818@qq.com Phone: +86 16626708626

Phone: +86 16626708626