Description

In the intricate machinery of industrial automation, where hydraulic systems in heavy presses or injection molding machines demand instantaneous pressure modulation to avert overloads or material defects, the frequent pain point is sluggish or imprecise solenoid actuation that leads to erratic flow control, heightened wear on valves, or non-compliance with ISO 4413 hydraulic standards. Envision a die-casting operation or a steel forging line: proportional solenoids must ramp pressures from 0 to 350 bar in under 50 ms based on PLC commands, but standard drivers introduce voltage droops from inductive kicks or EMI from adjacent welders, corrupting I/O signals and triggering safety halts that cascade into production bottlenecks. Off-the-shelf amplifiers might handle basic on/off duties, but they lack the current feedback precision for closed-loop tuning in high-reliability process control, where modular integration into DCS or safety PLCs requires deterministic response without custom shielding or heat sinks that bloat panel footprints.

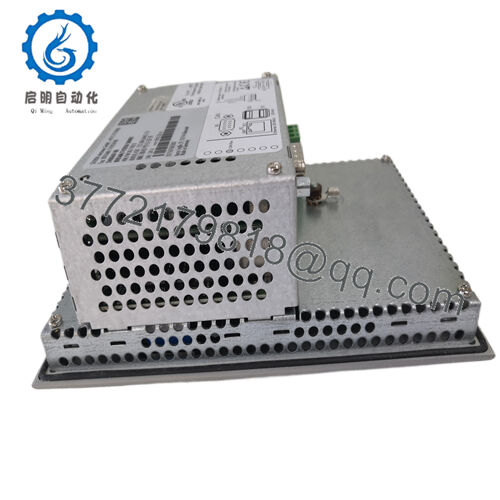

The Bosch Rexroth BT05AM702030-01 enters as a specialized proportional solenoid driver module from the VT-VSPA series, calibrated to orchestrate hydraulic valve pilots with surgical finesse in these exact crucibles. This unit quells the need for signal reliability by delivering PWM-modulated currents up to 3 A at 24 VDC, with integrated ramp generators that shape solenoid forces for smooth spool movements, all while providing analog feedback for drift compensation. In routine industrial automation deployments—like servo-hydraulic axes in automotive assembly or flow regulators in petrochemical skids—the Bosch Rexroth BT05AM702030-01 proves irreplaceable, fostering modular stacking in Eurocard racks that sync with Sercos or Profibus for real-time synchronization, minus the latency pitfalls of discrete components. Its galvanic isolation fortifies against transients up to 500 V, ensuring I/O signals from pressure transducers remain untainted in EMI-saturated zones.

- BT05AM702030-01

What captivates the engineer eyeing deployment is its inherent scalability for retrofits from legacy VT-2000 drivers, offering pin-compatible terminals and configurable dither frequencies to mitigate stick-slip in high-viscosity fluids, thereby slashing commissioning tweaks. For process control under IEC 61508, the Bosch Rexroth BT05AM702030-01 embeds fault monitoring that de-energizes on overcurrent, transforming vulnerable pilot circuits into resilient sentinels that align hydraulic kinetics with digital imperatives—delivering the poised precision that elevates throughput from tentative to triumphant in the unyielding tempo of automated fabrication.

The Bosch Rexroth BT05AM702030-01 resides as a pulse-shaping virtuoso in the actuator drive stratum of hydraulic stacks, DIN-rail or panel-mounting to condition PWM duty cycles from upstream controllers—sourced via ±10 V command inputs or digital SPI—for solenoid coils rated 12-24 ohms, achieving force linearity within 1% across 0-100% ramps. It amplifies these to bipolar outputs with current sensing via shunt amplifiers, feeding back via 4-20 mA loops for closed-loop trims that counteract coil heating or fluid temperature variances, all orchestrated by an onboard microcontroller for user-programmable profiles downloadable via USB.

In the automation echelon, the Bosch Rexroth BT05AM702030-01 perches downstream of safety PLCs like Siemens S7 or Rockwell GuardLogix, often daisy-chained in redundant pairs for 1oo2 voting where a peer mirrors ramps with <10 ms sync to sustain SIL 2 on valve faults, leveraging Profinet for cyclic parameter exchanges that enforce dither at 100-500 Hz to hush hydraulic chatter. Diagnostics gleam overtly: potentiometers tune gains on-site, while status relays and LED bars signal saturation or short circuits, with event latches queryable via Modbus RTU for SCADA historians. It mates natively with 4/3-way directional valves like 4WREE, dissipating 15 W peaks into aluminum heatsinks without fans, and supports enable interlocks to quiesce on e-stop. No bespoke enclosures; its IP20-rated polycarbonate shell slots into standard subracks, prioritizing sub-20 ms settling that meshes with servo loop closures.

This supple synergy extends to hybrid systems, where the Bosch Rexroth BT05AM702030-01 proxies analog commands to fieldbus objects, easing expansions from mono- to multi-axis hydraulics. For the deploying specialist, it’s the discerning director that presages spool stutters, ensuring your hydraulic symphonies swell with calibrated command, not cacophony of compromises, and integrate with the elegance that process poise demands.

| Specification | Details |

|---|---|

| Model Number | BT05AM702030-01 |

| Brand | Bosch Rexroth |

| Type | Proportional Solenoid Driver Module |

| Input Voltage | 24 VDC (±10%) |

| Operating Temp Range | -20 °C to +70 °C |

| Mounting Style | DIN Rail / Panel Mount |

| Dimensions | 100 x 22.5 x 115 mm (H x W x D) |

| Weight | 0.18 kg |

| Interface/Bus | Analog ±10 V, SPI, Modbus RTU |

| Compliance | IEC 61508 SIL 2, CE, ISO 4413 |

| Supported Protocols | Profinet, Sercos, Analog |

| Typical Power Draw | 10 W (nominal) |

Adopting the Bosch Rexroth BT05AM702030-01 instills a hydraulic harmony into your automation veins, where its current-loop fidelity quells inductive backlash that frays lesser drivers, anchoring long-term performance through self-compensating ramps that sustain spool accuracy amid 50 bar/sec transients—garnering MTBF over 200,000 hours to streamline spares in decentralized skids. This tenacity trims upkeep from frequent coil swaps to sporadic gain checks, with feedback telemetry that unveils hysteresis via oscilloscope taps, honing diagnostics from vague hunts to vector-specific verifications that reclaim shifts from stoppages.

Steadiness endures in tumult: 0.5% ripple at full duty synchronizes valve ports with PLC pulses, forestalling pressure overshoots that spike energy draws in servo presses, crucial for cycle times where 10 ms lags laminate yields. Engineering encumbrances ebb as well; its SPI port reprograms profiles sans ladder ladders, hastening field tunes and redirecting prowess from wiring webs to waveform wizardry, while dither presets adapt to oil grades without recals. Engineered for the hydrautician’s horizon, the Bosch Rexroth BT05AM702030-01 anticipates evolutions—like integrating with IO-Link for predictive valve health—yielding a driver that stewards not just ramps but realms, contracting CAPEX via fewer amplifiers, supple audits, and the subtle sagacity that lets pressures pulse productively, not perilously.

In injection molding bays, the Bosch Rexroth BT05AM702030-01 pilots clamp solenoids, modulating 200 bar rams in resin-vapor process control theaters, where its ramp shaping upholds critical system uptime against thermal drifts, calibrating shots for defect-free parts in high-cavitation molds.

Forging hammers deploy the Bosch Rexroth BT05AM702030-01 for directional valves, driving 350 bar flows amid forge-scale dust and 10 g jolts, backing rapid quench cycles in high-reliability forges that necessitate SIL 2 exactitude to avert billet bursts during peak tonnage strikes.

Automotive body shops leverage it in robotic grippers, conditioning gripper pilots in paint-booth humidity, with the Bosch Rexroth BT05AM702030-01‘s isolation ensuring nonstop panel transfers by muting weld-spatter EMI in continuous assembly lines that sync with vision systems for zero-gap welds.

BT05AM702030-02 – Variant with dual-channel outputs for tandem valve syncing in symmetric hydraulic axes.

VT-VSPA1-1X – Base predecessor for legacy VT-2000 migrations, with basic ramp but no feedback loop.

BT05AM702031-01 – Enhanced model with IO-Link for smart diagnostics in Industry 4.0 hydraulics.

4WREE10V1-50 – Paired proportional valve for direct BT05 drive in low-flow positioning tasks.

VT-VPSD1-1X – Analog-only sibling for non-digital retrofits in cost-sensitive pump controls.

IndraLogic XLC – Upstream PLC platform for command scripting tied to BT05 feedback in Sercos nets.

4WMM6 – Manual override valve add-on for safe BT05 de-energize in maintenance interlocks.

Hydraulics Rack – Eurocard enclosure for modular BT05 cascades in multi-pilot cabinets.

Before energizing the Bosch Rexroth BT05AM702030-01, equilibrate your 24 VDC bus to <50 mV ripple with a scope under mock load—imbalances breed PWM distortion—and calibrate command pots to 0-100% span via the onboard trimpots; fetch firmware baselines from Rexroth’s portal to embed Profinet profiles. Secure DIN clips at 1 Nm torque for 5 g vibes, and assay coil impedances at 12-24 Ω to nix shorts, while routing shielded analogs through ferrite clamps if exceeding 5 m to tame EMI ghosts. Etch 30 mm above/below for passive cooling in cabinets cresting 70 °C, and interlock enables to e-stops per EN 60204 to forestall runaway ramps.

In operational orbit, embrace regimens that exalt endurance sans excess. Biweekly, audit status LEDs—green for linear flow, red for saturation—and snag feedback traces in IndraWorks for ripple crests over 2%, retuning dithers if hysteresis tops 1°. Quarterly, pulse-test with a hydraulic bench at 80% duty, chroning settling under 20 ms for ISO 4413 records, and probe heatsinks for oxide in oily bays—wipe with ESD cloths, depowered to clear latches. For viscous or dusty domains, scrutinize terminals semiannually for pitting, verifying isolation at 500 VDC megger stays 20 MΩ, and mirror configs on a shadow rig pre-flash for valve fidelity. This attuned tempo, tethered to tonnage tides, fortifies your cadre to foster the Bosch Rexroth BT05AM702030-01‘s flair, alchemizing attrition into aptitude.

WhatsApp: +86 16626708626

WhatsApp: +86 16626708626 Email:

Email:  Phone: +86 16626708626

Phone: +86 16626708626