Description

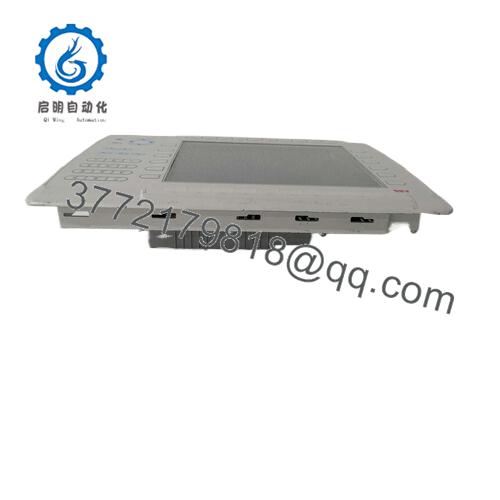

Product Model: ABB PP846 3BSE042238R1

Product Brand: ABB

Product Series: Panel 800 / PP-series (Operator Panel)

Product Features:

- 10.4-inch TFT display in Panel 800 family

- Supports both function keys and touch interfaces

- Multiple serial connections: RS-232, RS-485, RS-422 for HMI/PLC communication

- IP66 front protection, robust for industrial mounting

PP846 3BSE042238R1

Step 3 – Main Article

Technical Specifications Table

| Specification | Detail |

|---|---|

| Product Model | ABB PP846 3BSE042238R1 |

| Product Type | Operator Panel / HMI (Panel 800 series) |

| Display | 10.4″ color TFT, 800×600 resolution |

| User Interface | Function keys + touch capability (depending variant) |

| Serial Interfaces | RS-232, RS-422, RS-485 |

| Operating Temperature | Standard industrial range (check datasheet) |

| Front Protection | IP66 (front bezel) |

| Rear Protection | Typically IP20 for rear part |

| Power Supply | (See hardware manual) |

| Mounting | Panel cutout mounting, flush installation in control panel |

| Firmware / Software Version | Panel 800 PP846 Version 5.1 reference in ABB manual |

Applications & Industry Context

In many industrial automation systems, a human-machine interface (HMI) or operator panel sits between control logic and human operators. The ABB PP846 3BSE042238R1, part of the Panel 800 family, serves exactly that role: it provides a visual and interactive interface for monitoring, control, alarm displays, recipes, and parameter entry.

You’ll find the ABB PP846 3BSE042238R1 deployed in process plants, power stations, water & wastewater facilities, heavy industry, and manufacturing lines. It is used wherever operators need to see system states, change setpoints, acknowledge alarms, or track trends directly on the plant floor. Because operators cannot always rely solely on remote SCADA consoles, a robust, local operator panel like PP846 provides critical immediacy.

In retrofits, the PP846 is popular because it can often be dropped into existing cutouts (or slightly modified) to replace ageing panels. Its mix of function keys and touch input gives flexibility in environments where gloves or contamination may limit reliance on purely touch panels. In environments with dust, liquid spray, or vibration, the IP66 front protection ensures long life and operator confidence.

Another observation: in many plants, the human-machine interface becomes the “face” of the control system — if it lags, crashes, or is unreliable, operators lose trust. Installing a stable, responsive module like ABB PP846 3BSE042238R1 helps maintain operator confidence and smooth operations during shift changes, alarms, or maintenance windows.

Product Role & System Fit

The ABB PP846 3BSE042238R1 is fundamentally an operator / display interface — an HMI — sitting front and center in a control panel. Its role is to bridge automation logic (PLCs, controllers, DCS) with human operators. It does not make control decisions itself (unless it includes scripting or embedded logic, depending on configuration), but displays status, allows input, shows alarms and trends, and forwards commands.

In a system architecture, the PP846 connects via serial links (RS-232, RS-422, RS-485) or possibly Ethernet (depending on hardware variant) to controllers or I/O modules. It receives data (process variables, statuses) and sends back operator inputs (setpoints, control actions). Because it belongs to ABB’s Panel 800 series, its internal firmware and communication stack are optimized to integrate with ABB’s automation suite and legacy systems.

In many systems, multiple PP846 panels might be distributed across plant areas — e.g. near critical equipment, at local operator stations, or in control rooms. Each instance may run tailored screens, alarm summaries, and local controls. The PP846’s flexibility in screen design and object orientation ensures that operators get relevant views without overloading them with unnecessary detail.

Moreover, because the PP846 supports function keys and touch input, it fits into both older and newer interfaces — for example, in hazardous areas where touch may be disabled or gloves are used, function keys remain usable. This dual-mode usability makes ABB PP846 3BSE042238R1 versatile in varying operational settings.

Technical Features & Benefits

One essential advantage of ABB PP846 3BSE042238R1 is its Panel 800 firmware framework, which includes built-in capabilities for alarm management, recipe handling, dynamic objects, time channels, and user security. These built-in capabilities reduce the need for custom code and streamline project deployment.

The 10.4″ TFT display is bright, color-capable, and large enough to present multiple trends, status indicators, or summary information without overwhelming the operator. The screen’s resolution and clarity help reduce misinterpretation or operator fatigue during long shifts.

Its hardware is designed for durability: the front bezel meets IP66 protection, so it resists splash, dust ingress, and meets industrial robustness criteria. The rear typically is less sealed (IP20), but when installed in enclosures, protection is adequate.

Communications are versatile: you get serial ports that support RS-232/422/485, letting PP846 connect to a wide variety of legacy and modern devices. The ease of configuration ensures you can map screens to data sources or controllers without extensive reprogramming.

In terms of installation, the hardware manual shows the panel’s front is slim and mounts flush; the overall depth is moderate, giving some room for wiring and connectors behind the panel. Because the operator panel is often a critical element of daily operation, its reliability and usability become essential to system acceptance by operators.

From field experience, panels like PP846 often survive for long service life if properly mounted and ventilated. Many plants report over 10 years of use with minimal replacement, especially when spares are kept, firmware updates are managed, and protection (against surges, moisture, dust) is applied. The modular nature of Panel 800 also allows replacement of parts (e.g. screen, front glass) without needing to rewire entire systems in many cases.

Installation & Maintenance Insights

Mounting ABB PP846 3BSE042238R1 requires precision to maintain sealing and usability. The front panel cutout must match recommended dimensions, and the bezel must press evenly against the panel frame to maintain the IP66 rating. Uneven mounting can allow ingress of dust or moisture.

Behind the panel, allow clearance for connectors, cable bend radii, and ventilation. Do not pinch cables or run them too close to heat or high-power lines. Shielded cables are advisable for communication lines to reduce electromagnetic interference—especially in noisy industrial environments.

Ensure that ground referencing is consistent — ground loops or improper isolation on serial lines may lead to erratic behavior or communication errors. Many installation guides suggest routing power and signal lines separately, using proper shielding, and following ABB’s grounding practice.

Prior to commissioning, load the correct firmware and screen project file, verify display and responsiveness, test all function keys and touch zones, and simulate alarm conditions. Monitor the panel through a burn-in period to catch glitches early.

In regular maintenance cycles, inspect the panel bezel seal, check for ingress or condensation, and verify that the display remains bright and clear. Verify that the software version is still supported, back up display projects, and test communication with controllers. In high-use or harsh environments, more frequent checks (e.g. quarterly) may prevent downtime.

If panel screens become sluggish or unresponsive over time, older versions of Panel 800 may benefit from firmware updates or screen memory cleanup. Because the PP846 is modular, some replacements (such as front glass, touch overlay, or internal electronics) can sometimes be performed without removing the entire unit, provided proper handling.

WhatsApp: +86 16626708626

WhatsApp: +86 16626708626 Email:

Email:  Phone: +86 16626708626

Phone: +86 16626708626