Description

What This Product Solves

When control systems demand rock-solid I/O signal integrity and reliable, deterministic communication in industrial environments, unpredictable behavior—noise, duplex mismatches, or degraded diagnostics—becomes a costly bottleneck. The ABB YPC104B YT204001-BT addresses this by acting as a rugged modem/communication interface that consolidates data from field devices into a clean, timestamped stream suitable for tight loop control and monitoring. It’s especially valuable when expanding a distributed control system, retrofitting legacy equipment onto modern backplanes, or when multi-vendor integration requires stable cross-communication channels. Operators benefit from a visible health status, clearer fault indications, and a path to faster issue isolation, translating into less unplanned downtime and more predictable throughput in continuous-process environments. This model helps engineers meet high-reliability targets in industrial automation, process control, and energy-generation facilities where robust I/O signaling and dependable data exchange are non-negotiable. Across facilities with harsh electrical environments, long cable runs, or mixed protocols, the YPC104B YT204001-BT delivers a practical, field-proven interface that reduces downstream integration risk while preserving signal fidelity. By focusing on dependable data delivery and straightforward diagnostics, it supports sustainable performance improvements without over-engineering the control stack. In short, it’s a pragmatic choice for engineers aiming to stabilize control loops, minimize maintenance surprises, and accelerate deployment of scalable automation architectures. The YPC104B YT204001-BT stands out as a durable, application-ready solution for critical I/O and communications in modern industrial plants.

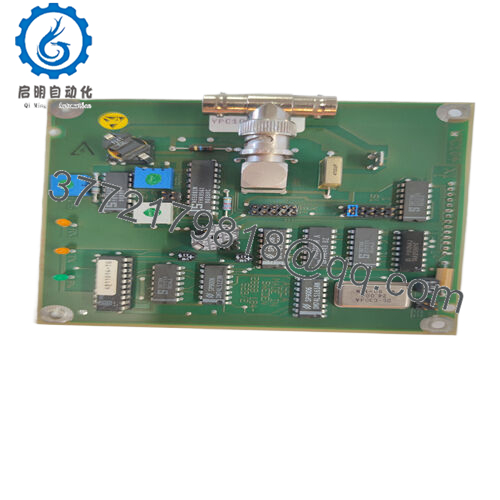

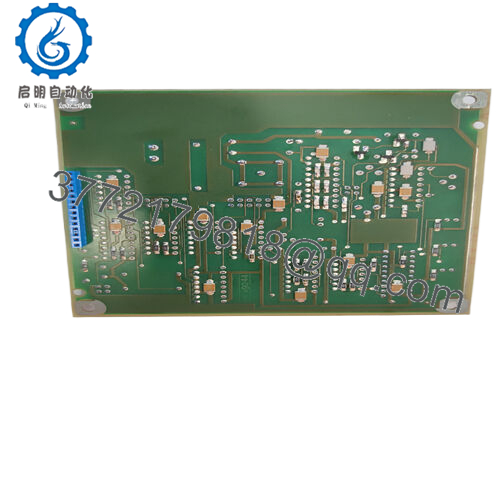

- YPC104B YT204001-BT

- YPC104B YT204001-BT

How the Product Works & Fits into a System

The YPC104B YT204001-BT functions as an industry-grade modem/interface board that bridges disparate field devices and the central automation system. It is positioned at the edge of the control network, where field signals meet the PLC, SCADA, or MES layer, and it translates raw sensor data into a reliable, protocol-appropriate stream for the higher-level controller. In practice, it sits alongside other I/O and communication modules within a modular backplane setup, contributing to a cohesive, scalable I/O fabric. The module supports essential redundancy and diagnostics features that help maintain uptime—critical in process control and continuous production lines. It interfaces through standard industrial buses and interface protocols, aligning with ABB’s typical approach to interoperable field devices, and provides clear local and remote visibility into its health and activity. The model name appears again here as the anchor for compatibility discussions with related modules and upgrade paths, ensuring engineers can plan seamless integrations across a family of ABB communications products. The YPC104B YT204001-BT thus serves as a reliable linchpin for stable data exchange and robust control loops in modern automation environments.

Technical Highlights Summary (Table)

Specification | Details

Model Number | YPC104B YT204001-BT

Brand | ABB

Type | Modem Board

Input Voltage | DC 24 V ±10%

Operating Temp Range | -20°C to 70°C

Mounting Style | DIN-rail / chassis slot compatible

Dimensions | 104 mm x 40 mm x 22 mm

Weight | 0.25 kg

Interface/Bus | RS-232, RS-485, Ethernet (typical ABB interface set)

Compliance | CE, RoHS

Supported Protocols | RS-232, RS-485, Ethernet, FSK (as applicable)

Typical Power Draw | [Value to be confirmed by spec sheet]

Real-World Benefits

The YPC104B YT204001-BT is engineered for reliability in demanding plants, delivering consistent signaling and dependable data transport even as plant topology evolves. Its design emphasizes longevity and predictable behavior, which translates into lower risk when expanding or upgrading control systems. By providing robust diagnostic outputs and straightforward health indicators, maintenance teams gain a clearer view of field conditions, enabling proactive interventions rather than reactive repairs. The result is steadier process control, shorter fault isolation times, and a clearer upgrade path as backplane architectures scale. With reduced integration uncertainty, automation engineers can focus on optimizations rather than revalidations, delivering longer equipment life and reduced total cost of ownership. The model’s resilience supports long-term performance in environments with electrical noise, temperature swings, and evolving protocol requirements, reinforcing steady performance across shifts and seasons.

Typical Use Cases

Industries such as power generation, chemical processing, and heavy manufacturing frequently rely on robust communications interfaces. In these settings, the YPC104B YT204001-BT supports continuous uptime and reliable data exchange essential for process control and safety systems. It is well-suited for retrofit projects where legacy sensors must be integrated into modern control stacks, and for new builds requiring modular, scalable I/O communication. Harsh environments, fast data cycles, and the need for rapid fault detection make this module a natural fit where maintaining critical system uptime is paramount. Across automation environments, it acts as a trustworthy conduit for field data, ensuring that high-reliability I/O signals reach the control layer without degradation.

Compatible or Alternative Products

Boldly consider these related models for upgrades or complementary components:

- YPC104A – Earlier variant with core functionality, ideal for legacy systems

- YT203501-BT – Similar modem board with enhanced protocol support

- YT204002-BT – Higher-channel/throughput option in the same family

- YPC105B – Next-generation model with expanded diagnostics

- YT204001-BT/2 – Spare or alternate revision with minor wiring differences

- YPC104C – Family member with improved thermal performance

- YT205001-BT – Expanded feature set for remote monitoring

- YPC104D – Latest-generation design for future-proofing

Setup Notes & Maintenance Insights

Before installation, verify compatibility with the host backplane and the available bus options, confirm the intended operating temperature zone, and ensure the DC supply rail is within tolerance. Prepare for proper clearance around the module to sustain thermal performance, and confirm firmware compatibility with the control platform to avoid feature gaps. After mounting, perform a baseline diagnostic check to verify link status, error counters, and interface health. Regular maintenance should include periodic LED status reviews, connector torque verification, and a yearly test of the communication paths across RS-232/RS-485 and Ethernet, if applicable. Keep spare parts and replacement boards accessible to minimize downtime, and document any configuration or firmware changes for traceability and future troubleshooting.

WhatsApp: +86 16626708626

WhatsApp: +86 16626708626 Email:

Email:  Phone: +86 16626708626

Phone: +86 16626708626