Description

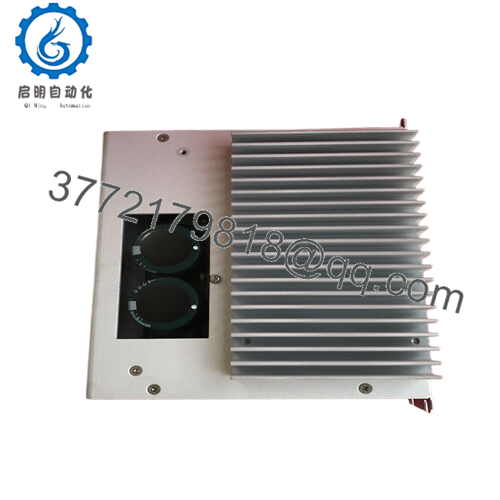

The Yokogawa CACR-02-KIBA is a compact servo drive designed to interface seamlessly with servo motors, acting as the bridge between the control system (such as a PLC or motion controller) and the motor itself. It works by receiving command signals from the control platform—typically position, speed, or torque setpoints—and converting these into precise electrical current outputs that drive the motor. Positioned in the automation stack between the upper-level controller and the servo motor, it plays a vital role in closing the control loop: it continuously monitors motor feedback (via encoders or resolvers) and adjusts its output in real time to maintain the desired motion parameters. The drive supports advanced control algorithms, including proportional-integral-derivative (PID) tuning, which allows engineers to optimize performance for specific applications. It also features built-in protection mechanisms, such as overcurrent, overvoltage, and overtemperature safeguards, to prevent damage to both the drive and the connected motor in fault conditions.

CACR-02-KIBA

Technical specifications:

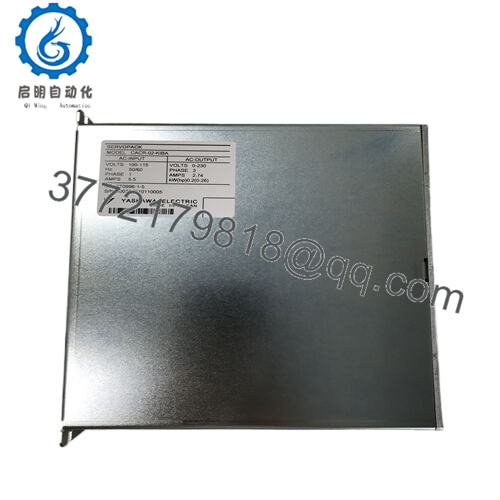

Model Number CACR-02-KIBA

BrandYokogawa

TypeServo Drive

Input Voltage200-240V AC (single-phase)

Operating Temp Range0 to 55°C

Mounting StylePanel mount

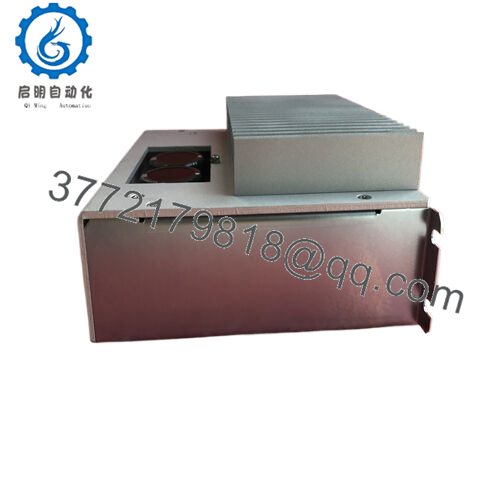

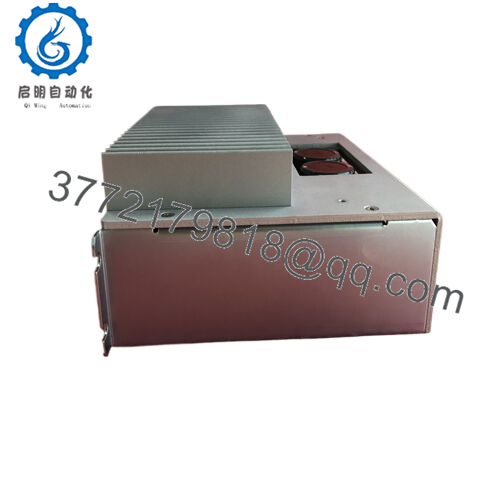

Dimensions120mm x 180mm x 100mm (WxHxD)

WeightApprox. 1.2 kg

Interface/BusRS-485, pulse train input

ComplianceCE, RoHS

Supported ProtocolsModbus RTU

Typical Power Draw200W (continuous)

contact us:

Phone:+86 16626708626

WeChat/WhatsApp:+86 16626708626

Email: [email protected]

CACR-02-KIBA

Main features and advantages:

Engineered for long-term performance in demanding industrial settings, the Yokogawa CACR-02-KIBA offers tangible benefits that directly impact operational efficiency. Its precise control capabilities ensure that servo motors maintain consistent performance even under varying loads, reducing product variability and minimizing waste in manufacturing processes. The drive’s compact design saves valuable panel space, making it ideal for control cabinets where real estate is at a premium—this reduces the need for larger enclosures, lowering overall system costs. Additionally, its built-in diagnostic features, such as error code displays and status LEDs, simplify troubleshooting, allowing maintenance teams to quickly identify and resolve issues without lengthy downtime. By ensuring reliable motor operation, the Yokogawa CACR-02-KIBA helps extend the lifespan of both the drive and the connected motor, reducing replacement costs and unplanned maintenance.

CACR-02-KIBA

Application areas:

The Yokogawa CACR-02-KIBA is deployed across a range of industries where precision motion control is critical. In electronics manufacturing, it’s used in pick-and-place machines, where it controls the servo motors responsible for placing tiny components onto circuit boards with micrometer-level accuracy—any deviation here could render the board useless. In packaging machinery, the drive ensures that conveyor belts and filling mechanisms operate at synchronized speeds, preventing misalignment of packages and ensuring consistent fill levels, which is essential for meeting quality standards. It’s also found in textile production, where it controls the motors that drive spinning and weaving equipment, maintaining uniform tension in threads to avoid breakages and ensure consistent fabric quality. In all these applications, the drive’s ability to handle fast response times and maintain stability under dynamic conditions is key to keeping production lines running smoothly.

CACR-02-KIBA

Related products:

CACR-02-KIBA

Installation and maintenance:

Before installing the Yokogawa CACR-02-KIBA, verify that the input voltage matches the drive’s 200-240V AC specification—using an incorrect voltage can cause irreversible damage. Check that the control signal from the PLC or motion controller is compatible with the drive’s input requirements (pulse train or analog signal, depending on configuration). Ensure the mounting panel is sturdy enough to support the drive’s weight and that there’s at least 30mm of clearance on all sides for proper ventilation, as the unit generates heat during operation. It’s also important to confirm that the servo motor is properly sized for the drive; mismatched motor and drive ratings can lead to poor performance or overheating. During ongoing maintenance, inspect the connectors quarterly for signs of corrosion or loose connections, especially in dusty or humid environments. Periodically check the drive’s status LEDs to ensure no error codes are present, and perform a yearly calibration check to maintain control accuracy.

Other product models of Yokogawa:

YOKOGWA AFV30D-A41252

Yokogawa SCP451-51

YOKOGWA TDLS8000

YOKOGWA 2104B2081

YOKOGWA AIP830-111/VESA

YOKOGWA AFV30D-A41152

YOKOGWA AAI143-H50/K4A00

YOKOGWA AAP135-S50

YOKOGWA ANB10D-415/CU2T

YOKOGWA ANB10D-415/CU2N

WhatsApp: +86 16626708626

WhatsApp: +86 16626708626 Email:

Email:  Phone: +86 16626708626

Phone: +86 16626708626