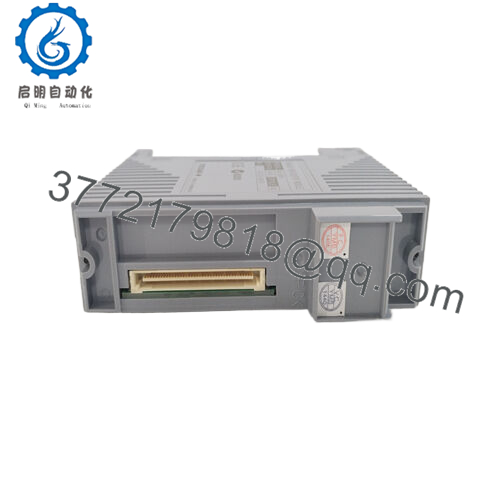

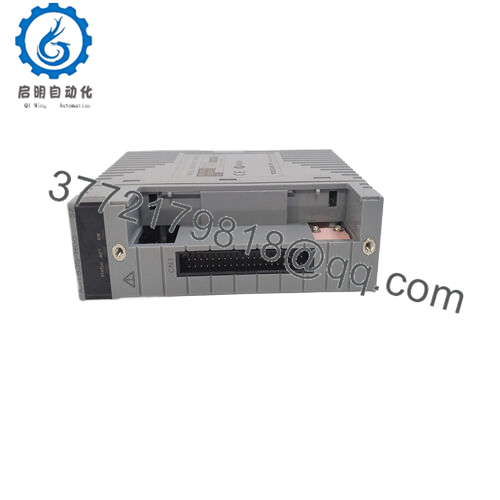

Description

The YOKOGAWA AAI835-H50 slots into Yokogawa’s AIP501 or AIP511 I/O unit, functioning as a key node in the CENTUM VP DCS architecture. Each module handles 8 analog channels with 16-bit resolution, communicating via the high-speed RIO bus to controllers like the FCS or ProSafe-RS safety PLCs.

AAI835-H50

Unlike generic I/O modules, it supports Yokogawa’s proprietary “Smart IO” diagnostics, flagging issues like open circuits, overrange signals, or hardware faults at the channel level—critical for predictive maintenance. Integration is seamless: the module auto-configures in Engineering Station (ES) software, and its hot-swappable design minimizes downtime during replacements. For redundancy, pairs of AAI835-H50 modules can be mirrored in TMR (Triple Modular Redundant) configurations, a common requirement in oil/gas shutdown systems.

AAI835-H50

Technical specifications:

Model Number AAI835-H50

Brand Yokogawa

Type Analog Input Module

Input Signals 4–20 mA, 0–20 mA, 0–5V, 1–5V

Channels 8 (isolated per channel)

Resolution 16-bit

Accuracy ±0.1% of span

Operating Temp Range -20°C to +60°C

Mounting AIP501/AIP511 I/O unit

Compliance IEC 61508 SIL2, CE, ATEX

Diagnostics Open wire, overrange, hardware fault

Power Consumption 1.8 W (typical)

contact us:

Phone:+86 16626708626

WeChat/WhatsApp:+86 16626708626

Email: [email protected]

AAI835-H50

Main features and advantages:

Deploying the YOKOGAWAAAI835-H50 means prioritizing operational certainty. Its channel-to-channel isolation eliminates cross-talk, ensuring each sensor reading remains uncompromised—a must for custody transfer metering or reactor temperature monitoring. The module’s SIL2 certification and fail-safe design make it a trusted choice for safety loops, while its ±0.1% accuracy reduces the need for manual calibration in hard-to-access field locations. Maintenance teams benefit from its diagnostic granularity: instead of hunting for faulty transmitters, the system pinpoints the exact issue, whether it’s a broken wire or a saturated signal. For brownfield upgrades, the module’s backward compatibility with legacy CENTUM systems simplifies migration without rewiring.

AAI835-H50

Application areas:

In LNG plants, the AAI835-H50 monitors cryogenic storage tank pressures, where signal drift could lead to overfill risks. Pharmaceutical manufacturers rely on its precision for bioreactor pH and dissolved oxygen control, where FDA compliance demands audit-ready data integrity. For offshore platforms, the module’s ATEX compliance and vibration resistance ensure reliable operation in Zone 1 hazardous areas. Across these scenarios, its blend of accuracy, diagnostics, and safety certifications addresses the pain points of high-availability process control environments.

AAI835-H50

Related products:

AAI835-S50 – Same specs with screw terminal connectors for vibration-prone installations

AAI143-H50 – 16-channel variant for high-density analog input needs

AAV141-S50 – Analog output counterpart for closed-loop control

ADV551 – Digital input module for safety system integration

AIP511 – Redundant I/O unit for fault-tolerant architectures

Installation and maintenance:

Before installation, verify the AIP501/AIP511 base unit’s firmware supports your CENTUM VP version (R6.xx or later). Use shielded twisted-pair cables for analog signals, and ground shields at the I/O unit side only to avoid ground loops. During operation, leverage Yokogawa’s PRM (Plant Resource Manager) software to track module health trends—proactively replacing units showing early warning signs (e.g., rising self-diagnostic error counts). Annual calibration checks are recommended, though the module’s long-term stability often extends this interval.

Other product models of Yokogawa:

YOKOGWA AFV30D-A41252

Yokogawa SCP451-51

YOKOGWA TDLS8000

YOKOGWA 2104B2081

YOKOGWA AIP830-111/VESA

YOKOGWA AFV30D-A41152

YOKOGWA AAI143-H50/K4A00

YOKOGWA AAP135-S50

YOKOGWA ANB10D-415/CU2T

YOKOGWA ANB10D-415/CU2N

WhatsApp: +86 16626708626

WhatsApp: +86 16626708626 Email:

Email:  Phone: +86 16626708626

Phone: +86 16626708626