Description

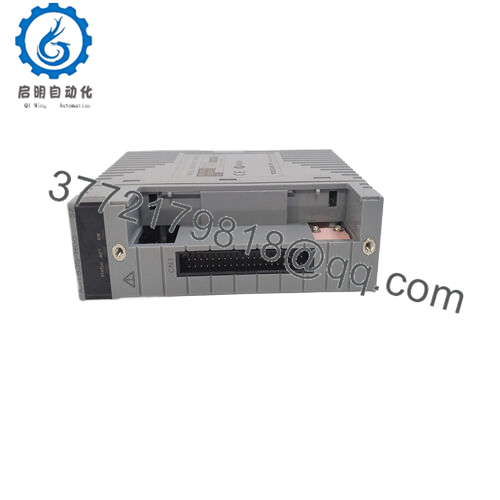

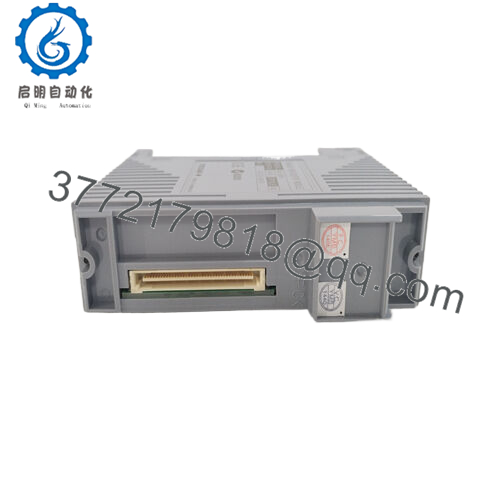

The YOKOGAWA AAI835-H50 is a high-performance analog input/output module primarily designed for use in Yokogawa’s CENTUM CS 3000 and VP distributed control systems. It plays a crucial role in industrial automation by converting field analog signals into digital data for process control and converting control system outputs back into analog signals for field devices. This module is essential in industries like oil and gas, chemical processing, power generation, and manufacturing, where accurate and reliable signal processing is crucial for maintaining operational stability and safety. The AAI835-H50 supports isolated 4–20 mA current signals for four input and four output channels, making it applicable in control systems that require meticulous, noise-free data acquisition and actuator control in high-availability, safety-critical scenarios.

- AAI835-H50

The YOKOGAWA AAI835-H50 serves as an analog I/O interface module within Yokogawa’s distributed control platforms. Its function is to seamlessly convert analog signals from field instruments (such as transmitters and sensors) into digital signals readable by the control system’s field control station (FCS). Conversely, it converts digital controller commands into analog signals for controlling actuators, valves, and other devices. Each channel within the module is electrically isolated, providing immunity to ground loops and minimizing signal interference, a key requirement in harsh industrial environments. The module comes equipped with HART communication capability, enabling advanced diagnostics and remote configuration of connected field devices, thereby simplifying maintenance and enhancing system robustness. Mechanical and electrical integration into node units (ESB bus nodes like ANB10S/ANB10D and optical nodes ANB11S/ANB11D) ensures compatibility across Yokogawa’s control hardware architecture.

Technical features of the AAI835-H50 include support for four channels of isolated 4–20 mA analog inputs and four channels of isolated 4–20 mA outputs. The isolation enhances signal integrity and protects the control system from electrical noise and interference common in industrial settings. With built-in HART modem functionality, up to 16 HART devices can be connected per module, facilitating multidrop communication and expanding instrumentation capabilities. The module maintains a fast HART data refresh cycle, about one second per device when fully populated, supporting timely and accurate process data updates. Its durable hardware design supports mounting within ESB bus node units and complies with stringent industrial controls. This module’s reliable conversion and communication features are indispensable for precise process control in complex automated plants.

| Parameter | Value |

|---|---|

| Model | AAI835-H50 |

| Brand | Yokogawa |

| Type | Analog Input/Output Module |

| Input Channels | 4 (4–20 mA DC, isolated) |

| Output Channels | 4 (4–20 mA DC, isolated) |

| Communication | HART protocol support (modem embedded) |

| Maximum HART Devices | 16 devices/module (multidrop up to 5 devices/channel) |

| HART Data Refresh Cycle | Approximately 1 second per device at full load |

| Mounting | Installed in ESB bus node units (ANB10S/ANB10D/ANB11S/ANB11D) |

| Isolation | Full channel-to-channel and system isolation |

| Application Systems | CENTUM CS 3000 and CENTUM VP Distributed Control Systems |

| Weight | Approximately 0.3 kg |

Related modules to the AAI835-H50 analog I/O unit include Yokogawa’s digital input/output modules for discrete control signals, temperature input modules for thermocouple and RTD sensors integration, and the AAI835 series variants optimized for different signal ranges or communication protocols. Interface node units like ANB10S and ANB11S provide essential connectivity for these modules within the DCS platform.

During installation, proper grounding and shielding of signal cables are critical to prevent noise interference, ensuring the isolated channels maintain high signal integrity. The module installation requires mounting within compatible ESB bus node units or optical nodes following Yokogawa’s hardware specifications. Ensuring firm, secure connections minimizes signal loss or disruption in complex bus architectures. Routine maintenance involves verifying signal accuracy, checking HART communications health, and monitoring module diagnostics through the host control system to preempt operational issues. Firmware updates and configuration changes should be performed using certified Yokogawa tools to safeguard system stability.

WhatsApp: +86 16626708626

WhatsApp: +86 16626708626 Email:

Email:  Phone: +86 16626708626

Phone: +86 16626708626