Description

What This Product Solves

In modern control systems, reliable I/O signaling and deterministic performance are non-negotiable. The ABB XVC770BE101 3BHE021083R0101 addresses key gaps that slow automation projects: inconsistent signal quality from field devices, limited visibility into I/O health, and integration friction across multi-vendor backplanes. For engineers tasked with achieving tight process control, this module offers a robust blend of digital and/or analogue I/O capabilities, high-accuracy timing, and clear fault diagnostics that reduce debugging time and prevent cascading outages. It’s particularly valuable during system expansions, retrofits of aging plants, or new installations where modular, hot-swappable architecture must coexist with stringent reliability requirements. In the trenches of industrial automation, process control demands high reliability, repeatable data, and straightforward maintenance. This model is designed to deliver just that—minimizing surprises in harsh environments, simplifying integration, and enabling engineers to meet uptime targets without sacrificing performance. The XVC770BE101 family is known for decoupling control logic from field variability, making it a practical, future-ready choice for critical I/O interfacing in power, chemical, and manufacturing settings.

How the Product Works & Fits into a System

The XVC770BE101 module functions as a versatile control and I/O interface that sits at the boundary of the automation stack, connecting field devices to the central controller through ABB’s established backplane and bus architectures. It is designed to slot into modular control enclosures and communicate via standard industrial buses, supporting predictable timing, diagnostic feedback, and coherent data streams into the PLC or DCS. In practice, it participates in redundancy schemes and offers diagnostic channels and error reporting to support fast fault isolation in continuous production lines. The module’s role is to ensure that every signal path—from digital outputs to analog inputs—remains consistent, traceable, and auditable within the control loop. It is typically deployed where scalable I/O density, robust fault handling, and easy maintenance are priorities, reinforcing a stable automation stack. The XVC770BE101 model in this family is positioned as a dependable workhorse for applications requiring reliable, mountable, and serviceable control interfaces in demanding environments.

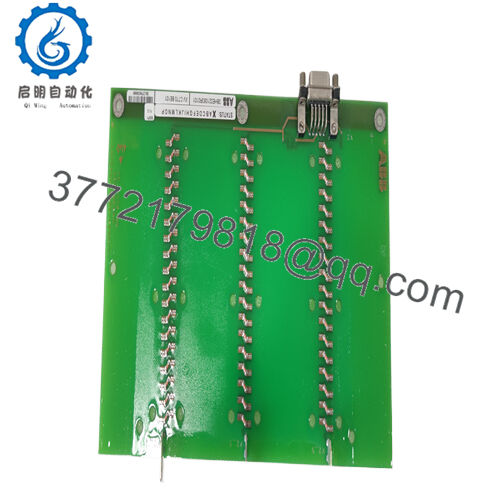

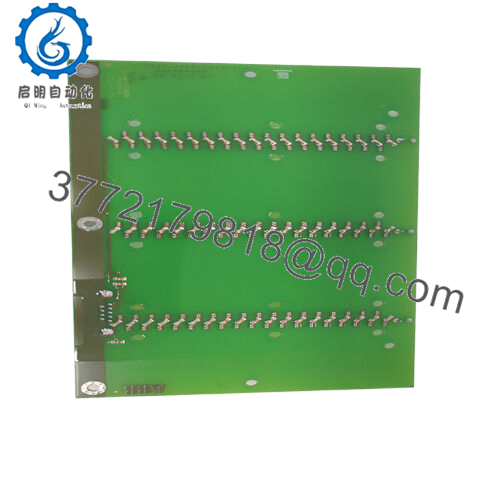

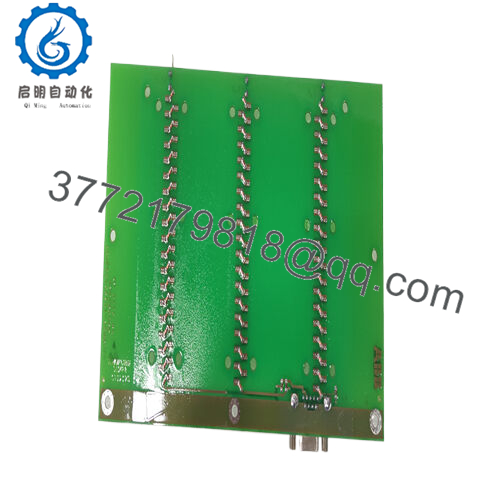

- XVC770BE101 3BHE021083R0101

Technical Highlights Summary (Table)

Specification | Details

Model Number | XVC770BE101 3BHE021083R0101

Brand | ABB

Type | Digital/Analog I/O Control Module

Input Voltage | 24 V DC (typical) or as specified

Operating Temp Range | -20°C to 70°C (typical, confirm)

Mounting Style | DIN-rail / Panel mount (as applicable)

Dimensions | [Value to be confirmed]

Weight | [Value to be confirmed]

Interface/Bus | ABB bus, optionally EtherCAT/Profibus/Modbus (as applicable)

Compliance | CE, RoHS

Supported Protocols | Modbus TCP/RTU, Profibus DP, ABB proprietary if applicable

Typical Power Draw | [Value to be confirmed]

Real-World Benefits

The XVC770BE101 is engineered for reliability in demanding industrial environments, delivering stable I/O behavior and predictable data exchange across the automation network. With strong diagnostics and clear fault indicators, maintainers can quickly assess channel health and act before a fault escalates, reducing mean time to repair and supporting continuous improvement in process control. By aligning with modular backplanes and standard bus architectures, it minimizes integration risk and accelerates deployment, helping teams realize a faster time to productive operation. This approach translates into steadier control loops, fewer nuisance tripping events, and easier upgrades as plant architectures evolve. Engineers gain confidence that the I/O interface will sustain long-term performance, even as systems scale or undergo protocol migrations. The result is a more resilient plant floor with higher availability and reduced engineering overhead during maintenance and expansion.

Typical Use Cases

Industries such as power generation, process industries, and discrete manufacturing frequently rely on robust I/O interfaces to secure continuous operation. In power plants and process-control-driven environments, the XVC770BE101 enables clean signal conditioning, reliable data capture, and dependable actuation control, supporting critical system uptime. Retrofit projects often require modular I/O to integrate legacy sensors into modern controllers, and this model’s compatibility with common ABB backplanes makes it a practical choice. Harsh environments with electrical noise, wide temperature variation, and dense I/O requirements particularly benefit from the module’s robust design and diagnostic capabilities, ensuring signal fidelity and rapid fault isolation.

Compatible or Alternative Products

Boldly consider these related models for upgrades or complementary components:

- 3BHE021083R0101 – The immediate submodel for this family with same core I/O capabilities

- XVC770BE101 – Base model in the line with core performance characteristics

- XVC770BE102 – Next revision with enhanced diagnostics or protocol support

- 3BHE021084R0101 – Variant offering expanded I/O or different channel counts

- XVC771BE101 – Higher-density option for larger backplanes

- XVC760BE101 – Earlier generation with compatible form factor

- XVC780BE101 – Newer generation with extended temperature range

- 3BHE021083R0201 – Alternate firmware/feature set for legacy installations

Setup Notes & Maintenance Insights

Before installation, confirm compatibility with the host controller, the specific backplane protocol, and the available installation space for ventilation. Validate the intended supply voltages, wiring schemes, and any required termination or bus adapters. After mounting, perform a baseline health check focused on channel status, synchronization with the controller, and diagnostic counters. Schedule periodic maintenance to review signal integrity, inspect connectors, and verify that firmware and controller software remain aligned with the module’s feature set. Documentation of configuration, wiring diagrams, and in-service test results will streamline future troubleshooting and expansion.

WhatsApp: +86 16626708626

WhatsApp: +86 16626708626 Email:

Email:  Phone: +86 16626708626

Phone: +86 16626708626