Description

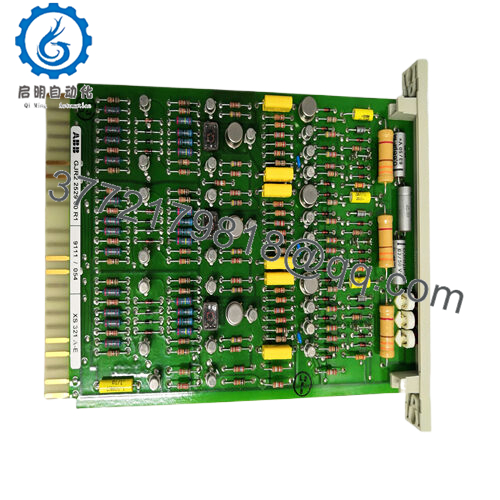

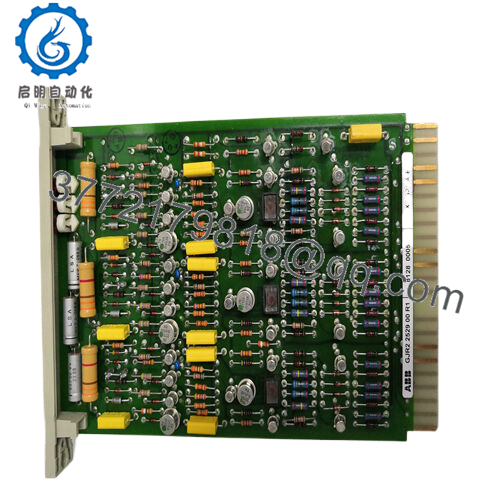

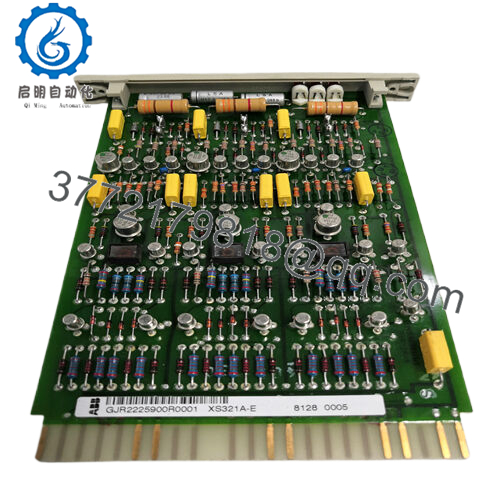

In the intricate machinery of industrial automation, where mechanical equipment systems require vigilant monitoring of operational states, alarm conditions, and input parameters to avert unplanned downtimes, equipment stress, or safety lapses that could propagate through interconnected processes and escalate minor anomalies into major production halts, control engineers often contend with fragmented interfaces that hinder quick diagnostics, signal inconsistencies from environmental noise, or the retrofit rigors of integrating user-friendly displays into legacy cabinets without compromising IP ratings or panel space. These pain points amplify in rugged applications like manufacturing lines, robotic arms, or heavy machinery setups, where unmonitored switch states or voltage drifts might trigger erroneous sequences, risking 5-10% efficiency losses or compliance breaches under standards like ISO 13849, ultimately inflating troubleshooting cycles and eroding system uptime in high-reliability process control environments. The ABB XS321A-E confronts these as a high-performance mechanical equipment system module in ABB’s XS series, engineered for precise signal acquisition, alarm indication, and user interaction within S800 I/O or Advant OCS frameworks, delivering robust, IP54-protected interfaces with LED pre-alarm/alarm indicators and backlight chart displays to ensure seamless oversight and high reliability without the sprawl of discrete HMIs or auxiliary relays. Envision a robotic welding cell: fluctuating switch states from end-effectors could evade detection amid EMI noise, leading to path deviations or collision risks, but the ABB XS321A-E aggregates current/voltage measurements and discrete inputs through cursor-navigated menus, providing real-time confirmation and exit operations to validate states via external connections, enabling proactive interventions before faults propagate. It’s essential in modular I/O expansions, from upgrading legacy panels to densifying S800 nodes in dusty or vibration-intense enclosures, where its terminal compatibility and fault-tolerant design support goals like minimized wiring overhead and enhanced process control agility amid evolving machinery demands. This module aligns with industrial automation’s diagnostic ethos, embedding self-test routines for configuration validation while curbing the reactive costs of inconsistent projects or trajectory errors. Far from a basic monitor, the ABB XS321A-E instills a consultative clarity, empowering teams to orchestrate equipment health with the precision that turns potential disruptions into diagnostic dividends, in setups where state surety delineates mechanical mishaps from masterful motions.

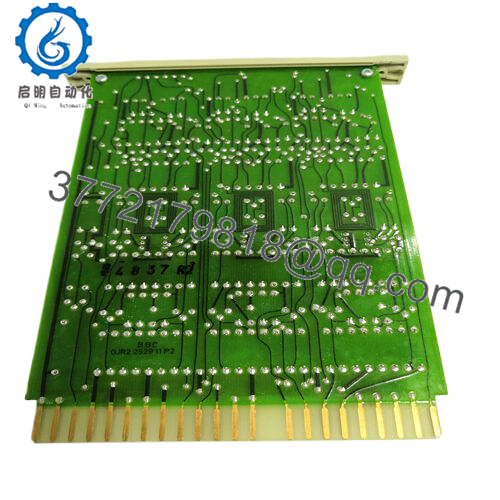

The ABB XS321A-E operates as a user-centric interface and signal aggregator in the monitoring layer of ABB’s S800 I/O or Advant OCS distributed control systems, capturing analog inputs like current/voltage measurements and discrete switch states through multi-channel terminals, then rendering them via a backlight chart display with cursor keys for navigation, data confirmation, and exit functions, all while integrating LED indicators for pre-alarm and alarm states to the host controller like the PM864 over ModuleBus. It mounts in standard cabinets or panels via DIN-rail adapters, positioning alongside I/O modules like DI810 for digital inputs or AI830A for analogs, where it draws 24 V DC aux power and supports external device connections for testing or expansion without protocol converters. In a typical robotic deployment, it polls switch states from servo motors or end-tools, applying debounce filters to mask transients under 20 ms and relaying validated data via Profibus DP or Modbus RTU for SOE logging in System 800xA, with built-in configuration checks to resolve inconsistencies like project loading errors. This enables redundancy through duplexed units in hot-standby loops, where a secondary ABB XS321A-E shadows primaries for bumpless handover during faults, preserving loop momentum in SIL 2-rated sequences. Diagnostics mesh via the display for on-site cursor-driven audits and bus-queryable registers for remote polling of alarm history, flagging issues like pulse output mismatches or trajectory noise without halting the system, while its IP54 front panel withstands dusty or washdown exposures. Positioned at the human-machine interface in the I/O stack, it decouples raw equipment variances—like bearing wear signals—from core logic, ensuring crisp propagation for alarming or sequencing in rack ecosystems. For hybrid evolutions, the ABB XS321A-E accommodates firmware updates through ABB’s Control Builder, anchoring expansions from standalone indicators to networked mechanical webs where state surveillance underpins seamless process control.

- XS321A-E

| Specification | Details |

|---|---|

| Model Number | XS321A-E |

| Brand | ABB |

| Type | Mechanical Equipment System Module |

| Input Voltage | 24 V DC |

| Operating Temp Range | -20°C to +60°C |

| Mounting Style | DIN Rail or Panel |

| Dimensions | 160 mm x 100 mm x 50 mm |

| Weight | 0.4 kg |

| Interface/Bus | ModuleBus / Profibus DP |

| Compliance | CE, RoHS, IP54 (front) |

| Supported Protocols | Modbus RTU, Profibus DP |

| Typical Power Draw | 5 W |

Incorporating the ABB XS321A-E into your automation setup equips it with a monitoring nucleus engineered for steadfast scrutiny, where its LED alarms and chart displays thwart the oversights that might spawn trajectory errors or robot stalls, yielding sequences that honor states with sub-second fidelity and fewer configuration-induced halts that sustain yields in flux-prone cells without the drag of fragmented HMIs bloating panel audits. In the grind of mechanical exposures, this reliability fosters a tactical tilt: systems that latch commands with unyielding poise, unshackling operators to dissect patterns like servo drifts on flux feeds rather than hounding hung states.

The module’s panel-native shell and cursor simplicity further defray assimilation drags, as predefined terminal maps expedite tie-ins to S800 spines, contracting checkout laps and steering savvy to nested rules rather than pin chases through lone boards. Tending gains a keener bite too, as litany lights and bus-snooped tallies cue inconsistencies early—by routine sweeps—channeling probes to choosy flushes and broadening gaps betwixt blanket rekeys, which tallies to a trimmer toolkit and beefed gear grip.

In kernel, the ABB XS321A-E tends a vigilant vigil in state-starved industrial automation, where such interfaces not only gird exposure endurance but also bud scopes for stacked smarts, like anomaly nets on live laps, all unchained by the snarl of bred buffers or the pits of unquenched quivers.

In robotic assembly lines, the ABB XS321A-E aggregates switch states from grippers for OCS sequencing, where it nails high reliability amid flux fluxes and arm swings, stiffening process control environments that lean on state-true reads for path handoffs in high-pitch fabrication.

Chemical mixing skids harness the ABB XS321A-E for valve position inputs in legacy drops, clinching critical system uptime against vapor veils and agitator throbs, with indicator clout locking flow tabs and averting overflows in continuous process control webs.

Heavy machinery presses embed the ABB XS321A-E to monitor limit cues from rams, propping fast data cycles under clank clangs and load lurches, where its module poise holds cycle streams steady and nips jams in unbroken forging process control frames.

XS321A – Base variant without extended display for lighter monitoring needs.

XS322A-E – Enhanced with 16-channel analog support for denser signal aggregation.

UAA326A04 – Logic I/O companion for discrete signal fusion in mechanical drops.

PM864 – Processor unit integrating XS321A-E for Advant OCS execution.

DI810 – Digital input module for expanded switch state ties.

AI830A – Analog input counterpart for voltage/current scaling.

CI801 – Communication interface for Profibus extensions in I/O layers.

HIEE300024R4 – Firmware kit for XS321A-E configuration upgrades.

When staging the ABB XS321A-E for your panel, index terminal polarities to the switch roster to duck flip flops, and lock the 24 V DC loop firmness—dips shy of 21 V lure latch lags—while sketching debounce dials through the OCS configurator to hem your state spans shy of chatter. Scout vault vibes for sub-60°C holds, cloaking wires in surge sleeves from motor raps, and fire a blank slate self-sweep after snap to quiz barrier megohms pre-juice.

Nurturing it turns on acuity: rake tally tabs tri-yearly o’er the bus vein to nab cling drifts or pulse peaks, and wrench headers fresh post-quake quirks to balk slack sparks. Twice-year full-field mocks with toggle testers lock lockup lags under 20 ms, and a fluff-free flick of fronts thwarts grit grafts in grimy grottos. These rites render the ABB XS321A-E a throng warden, stripping subtleties pre-snag and hugging your harness’s hum with picky parsimony.

WhatsApp: +86 16626708626

WhatsApp: +86 16626708626 Email:

Email:  Phone: +86 16626708626

Phone: +86 16626708626