Description

WOODWARD PEAK200-HVAC 8200-1501 is a high-performance programmable controller designed specifically for HVAC and building automation. As part of the Woodward PEAK200 series, it serves as the ‘central nervous system’ for HVAC systems, managing everything from simple relay control to complex multivariable PID loops. Unlike general PLCs, this controller has pre designed functional blocks for HVAC specific tasks, such as chiller sorting, demand controlled ventilation (DCV), and enthalpy control, which can reduce project time by up to 50%.

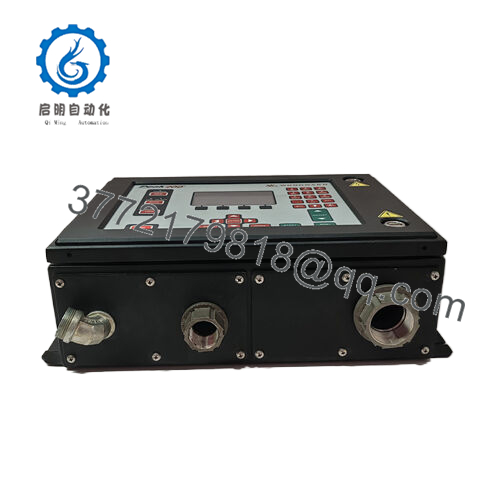

PEAK200-HVAC 8200-1501

The controller is built on a robust hardware platform (IP20 protection level, operating temperature range of -40 ° C to+70 ° C) and can operate in harsh data center environments while providing deterministic performance. Its modular design supports expandable I/O, suitable for small rooftop units or large central power stations. The intuitive Pro Suite programming software for controllers allows engineers to design custom strategies using ladder diagrams, functional block diagrams, or structured text, and drag and drop pre built HVAC algorithms.

As a future oriented solution,PEAK200-HVAC 8200-1501 seamlessly integrates with cloud platforms through secure Ethernet and supports protocols such as MQTT and OPC UA. This enables predictive maintenance (such as predicting fan belt failures through vibration analysis) and real-time occupancy based adjustments, which are crucial for facilities adopting intelligent building plans.

PEAK200-HVAC 8200-1501

Main features and advantages:

Adaptive control algorithm: The advanced PID self-tuning function can maintain precise temperature/humidity control (± 0.5 ° C/± 2% RH), while the adaptive learning function can be adjusted according to seasonal changes or equipment aging. For example, optimizing boiler start-up time in winter to efficiently preheat space without overshoot.

Multi protocol connectivity: Native support for BACnet MS/TP, Modbus RTU/IP, and Ethernet/IP, seamlessly integrating with legacy building automation systems (BAS), variable frequency drives (VFDs), and smart meters. The built-in web server allows remote configuration through any browser without the need to use proprietary software on-site.

Energy optimization kit: includes functions such as night ventilation, load reduction, and demand control, which can reduce energy costs. In retail malls, enthalpy control can be switched to outdoor air when the ambient humidity is low, which can reduce cooling load by 15-20% in mild weather conditions.

Redundancy and reliability: The optional dual controller redundancy function ensures zero downtime during failures, while the built-in diagnostic function monitors I/O health, network latency, and thermal performance. Notify the team in real-time via email/SMS of abnormal situations, such as AHU motor failure or air door jamming.

Scalable I/O architecture: Hot swappable digital/analog modules (such as the 8200-1502 expansion kit) allow for on-site upgrades without shutting down the system. This is crucial for renovation projects, as CO ₂ sensors or VFD controls can be gradually added.

PEAK200-HVAC 8200-1501

Technical specifications:

Model PEAK200-HVAC 8200-1501

Brand Woodward

Type HVAC Programmable Controller

Power supply 24 V DC/100-240 V AC (automatic induction)

I/O capacity of 32 local points (16 DI/16 DO or 8 AI/8 AO), expandable to [X] points

Communication 2x Ethernet (10/100 Mbps), 2x RS-485 (BACnet/Modbus)

Protocol BACnet IP/MS/TP, Modbus RTU/IP, MQTT, OPC UA

Working temperature -40 ° C to+70 ° C

Size 150 x 100 x 75 mm (DIN rail installation)

Weight 0.8 kg

Programming Pro Suite (ladder diagram/functional block diagram/structured text)

UL 508, CE, BACnet certification RoHS

contact us

Phone:+86 16626708626

WhatsApp/WeChat:+86 16626708626

Email: 3772179818@qq.com

PEAK200-HVAC 8200-1501

Application areas:

WOODWARDPEAK200-HVAC 8200-1501 is the core component of intelligent building automation. This controller is designed to address complex HVAC system management challenges, optimize comfort, reduce energy waste, and ensure compliance with regulatory requirements in various applications.

For example, in a 24/7 data center, PEAK200-HVAC 8200-1501 dynamically adjusts cooling loads by integrating with rack level temperature sensors and uninterruptible power supply (UPS) systems, ensuring that IT equipment operates within safe operating ranges while reducing energy costs by up to 30%. In the hospital, it maintains strict air quality standards in the operating room by regulating the air handling unit (AHU), using real-time data from particle counters to adjust fan speed and filter replacement. In large manufacturing plants, the controller manages rooftop units (RTUs) and boilers, adapting to seasonal demand changes and equipment wear to prevent unexpected shutdowns.

PEAK200-HVAC 8200-1501 performs well in hybrid systems that require integration with legacy systems. In a renovated office building, the old pneumatic control system is connected to a modern IoT platform through BACnet/IP, allowing facility managers to monitor energy usage through a cloud dashboard while ensuring compliance with ASHRAE 90.1 standards. Its scalability also makes it very suitable for new construction projects, such as smart campuses, where it can work in conjunction with solar thermal systems and ground source heat pump systems to achieve net zero emissions targets.

PEAK200-HVAC 8200-1501

Related products:

WOODWARD 8200-1502- I/O Expansion Module, capable of adding 16 digital/analog points for system expansion in large facilities.

WOODWARD BAC-500- BACnet gateway, can be integrated with legacy pneumatic or analog BAS systems.

Danfoss VLT Drive – Variable Frequency Drive (VFD) achieves precise fan/pump speed control through Modbus interface, improving energy efficiency.

Honeywell Excel 50- BAS platform, pre built drivers ensure seamless data exchange and centralized monitoring.

Siemens QAM1630- Temperature and Humidity Sensor provides real-time data for PEAK200-HVAC to optimize control circuits.

Johnson Controls Metasys – Building Management System (BMS), integrated through BACnet, enables enterprise level energy reporting.

PEAK200-HVAC 8200-1501

Installation and maintenance:

Installation:

Wiring: Use shielded twisted pair cables for RS-485 signal transmission to reduce electromagnetic interference (EMI), and use Cat5e cables for Ethernet connection. Separate the power/control cables from the sensor wiring to avoid interference.

Network settings: Configure static IP addresses for reliable BACnet/IP communication. Only enable DHCP in the secure subnet. Use VLAN to isolate HVAC traffic from other building systems.

Calibration: Verify the accuracy of the sensor during debugging (e.g. calibrate the humidity probe using a handheld hygrometer). Use descriptive labels in Pro Suite to map all I/O points (e.g. “AHU-1 supply air temperature”).

maintain:

Monthly Health Check: View error logs, trend data (such as fan energy consumption), and device uptime in the Pro Suite dashboard. Test emergency coverage function (such as manually shutting down the chiller).

Annual in-depth inspection: Update the firmware to the latest version (backup the program first). Check for loose connections in the wiring terminals, especially in high vibration areas such as mechanical rooms.

Predictive maintenance: Use the built-in analysis function of the controller to identify wear patterns (e.g. an increase in VFD current indicates motor degradation). Arrange component replacement during planned downtime.

HIMA Other Product Models:

HIMA PS1000WR011

HIMA F3DIO20/802 982200484

Hima F8621A

HIMA F8627X 984862765

HIMA 80105 984080105

HIMA ELOP II V5.5

HIMA 80105 984080105

HIMA X-SB01 985210207

HIMA F8628X

HIMA F8650X 984865065

HIMA A1-dig 984200004

HIMA X-AI3201 985210213

HIMA TRIX F35 982200416

HIMA F3DIO20/802 982200442

HIMA F8650E

HIMA F3226A

HIMA F8621A 984862160

HIMA F-PWR01

HIMA F3DIO16/801

HIMA Z7130

HIMA F3240

HIMA F30 03 SILworX 20/9

HIMA F3237

HIMA F8651X

HIMA F3DIO20/802 982200404

HiMA F35 030 34 SILworX

HIMA F-COM01

HIMA F-IOP01

HIMA F30 F30 010 20 OS-REV.V6.46/V11.28

HIMA F30 F30 010 20 OS-REV.V6.46/V11.28

WhatsApp: +86 16626708626

WhatsApp: +86 16626708626 Email: 3772179818@qq.com

Email: 3772179818@qq.com Phone: +86 16626708626

Phone: +86 16626708626