Description

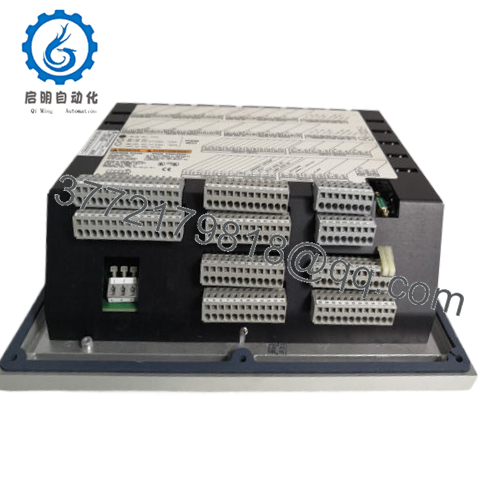

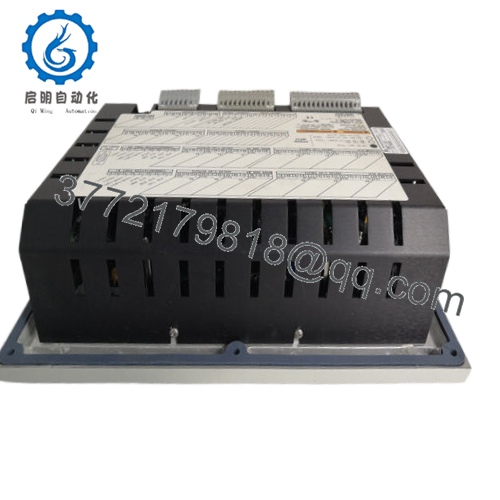

The Woodward 9907-167 is a 505E series digital governor designed specifically for steam turbines with controlled extraction and/or admission pressure regulation. It serves as the digital control hub that manages turbine speed, load, and pressure to ensure efficient, safe, and reliable operation. This module is widely used in industries such as power generation, petrochemicals, and chemical processing, where precision control of steam turbines is critical for optimizing plant performance, preventing mechanical failures, and safeguarding equipment longevity. Its suitability for industrial-sized steam turbines and small turbo generators makes it applicable in demanding control system architectures requiring high accuracy and robust protection functions.

- 9907-167

The 9907-167 features a 32-bit microprocessor housed in a rugged enclosure that can be securely mounted within control panels. It includes multiple analog inputs/outputs, relay outputs, and digital I/O channels capable of interfacing with various sensors, actuator outputs, and protection systems. The governor supports sophisticated control algorithms for speed regulation, pressure control, and load sharing functions. Its user interface includes a keypad with analog keys and a display that facilitates programming, uploading, and downloading of operational parameters. The module is designed to operate within an ambient temperature range of -25°C to +65°C (extended versions up to 70°C) and comes with an optional NEMA 4X waterproof enclosure for protection against harsh environments.

Technically, the Woodward 9907-167 offers:

| Parameter | Value |

|---|---|

| Model | 9907-167 |

| Brand | Woodward |

| Product Type | 505E Digital Governor for Steam Turbines |

| Processor | 32-bit microprocessor |

| Power Supply | 18–32 V DC with short circuit and overload protection |

| Analog Inputs | 8 differential analog inputs (16-bit resolution) |

| Analog Outputs | 2 analog outputs |

| Digital I/O Channels | 32 digital I/O |

| Relay Outputs | 8 relay outputs (6 programmable) |

| Communication | Dual Modbus (RS-232/422/485) with ASCII/RTU protocols |

| Operating Temperature | -25°C to +65°C (standard), up to +70°C optional |

| Protection Rating | Optional NEMA 4X enclosure for water/dust protection |

| Certifications | CE, UL, cUL |

The governor supports sophisticated features including reconfigurable FPGA architecture for real-time signal processing, multi-parameter control for speed and pressure regulation, independent overspeed shutdown, watchdog timers, and enhanced EMI/RFI protection compliant with industrial standards. It supports flexible startup modes including automatic warm-up and critical speed avoidance, optimizing turbine startup and operational safety.

Related products include other members of the 505E series such as the 9907-165 and 9907-166, differentiated by power supply types and input configurations, allowing customization to specific plant environments and turbine requirements.

Installation of the 9907-167 typically involves DIN rail or panel mounting within protective enclosures with proper electrical grounding and shielding to maintain signal fidelity in electrically noisy environments. Wiring best practices call for twisted-pair shielded cables and separation from power lines to reduce interference.

Maintenance procedures focus on terminal inspection, calibration of sensor linearity, firmware updates, and diagnostic checks via the user interface or remote communication tools. The product’s modular design and extensive documentation enhance ease of serviceability and integration into existing control systems.

WhatsApp: +86 16626708626

WhatsApp: +86 16626708626 Email:

Email:  Phone: +86 16626708626

Phone: +86 16626708626