Description

The Woodward 9907-1200 is extensively used in industrial automation environments that control steam turbines and other industrial engines requiring precise valve positioning. Commonly found in power plants, petrochemical refineries, and heavy industrial plants, this advanced digital control module manages the positioning of single-acting steam turbine valve servos through electrohydraulic means. It is particularly essential in systems where accurate control of steam flow directly impacts turbine speed, load management, and overall process efficiency.

Operators and engineers favor the Woodward 9907-1200 because it converts electrical control signals into proportional hydraulic pressures, enabling smooth and accurate valve movements critical in steam turbine operations. This converter addresses challenges such as maintaining turbine speed under varying load conditions and reducing mechanical wear by ensuring precise valve positioning in demanding process environments. Its robust performance in harsh industrial settings makes it applicable not only in turbine control but also in other electrohydraulic control scenarios requiring reliable signal-to-pressure conversion.

Product Introduction and Positioning

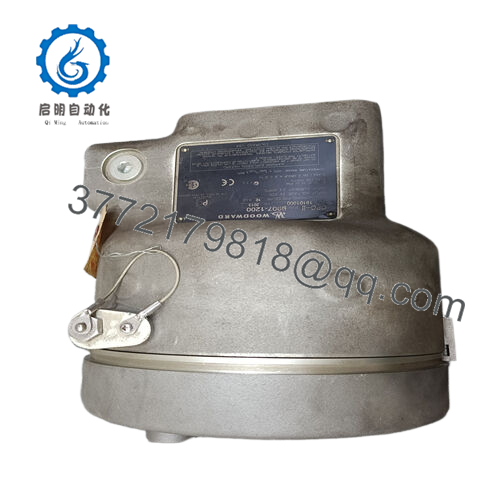

The Woodward 9907-1200, also known as the CPC-II Current-to-Pressure Converter, serves as a sophisticated electrohydraulic valve control unit used within turbine and engine management systems. It is designed to convert an electrical input current into a hydraulic pressure output, which actuates steam turbine valves with high precision. Positioned as a key component in turbine speed and load control loops, the module enables enhanced dynamics and robust performance in complex control architectures.

Part of Woodward’s lineup of turbine control automation solutions, the 9907-1200 integrates neatly into existing control systems, supporting Zone 1 and Zone 2 hazardous area certifications. It is configurable for simplex single-acting valve servo applications, offering engineers a flexible tool to upgrade or maintain turbine control systems. Its role is to optimize valve positioning by balancing electrical commands with hydraulic output, thus ensuring responsive and stable turbine operation.

The module’s compact and rugged design coupled with advanced control features makes it valuable for system integrators seeking reliable, scalable solutions to meet evolving turbine control demands.

Key Technical Features and Functional Benefits

The Woodward 9907-1200 excels with enhanced dynamic characteristics that provide quick and accurate responses to electrical control signals, ensuring precise valve positioning critical for turbine performance. It features a powerful actuator capable of delivering up to eight amps to drive actuator movement at optimal speed and torque, while thermal current limits protect the internal components from overload.

Its electrohydraulic valve incorporates a unique single-moving rotary design with self-cleaning ports that resist contamination and reduce maintenance needs. The unit supports redundant inputs from one or two controllers, as well as internal and external oil pressure sensor feedback, enabling stable and fail-safe operation in demanding applications. This redundancy option simplifies wiring and increases the overall reliability of turbine control systems.

- 9907-1200

For system adaptability, the 9907-1200 includes a manual override function allowing local adjustment of output pressure, alongside remote configuration and calibration via a service tool. It features an eleven-point linearization table to compensate for non-linear valve flow characteristics and a silt buster function to periodically flush potential contaminant buildup, both optimizing turbine control and longevity.

Its robust operating temperature range (-40°C to +85°C) and IP66 ingress protection ensure functionality in challenging environmental conditions, while the compact form factor and flexible mounting options facilitate straightforward integration into control panels.

Detailed Technical Specifications

| Parameter | Value |

|---|---|

| Model | 9907-1200 |

| Brand | Woodward |

| Product Type | Current-to-Pressure Converter (CPC-II) |

| Pressure Range | 0 to 10 bar (0 to 145 psi) |

| Input Signal | 4 to 20 mA (configurable) |

| Output Signal | Electrohydraulic pressure control |

| Operating Temperature | -40 to +85 °C |

| Power Supply | 18 to 32 V DC, nominal 24 V DC |

| Max Current Output | 8 Amps |

| Mounting | Face mounting with threaded holes |

| Protection Rating | IP66 |

| Redundancy Support | Yes (dual input/controller capable) |

| Dimensions (approx.) | 290 x 270 x 270 mm |

| Weight | Approximately 25 kg |

Related Modules or Compatible Units

9907-1100 – Similar current-to-pressure converter supporting different pressure ranges for varied turbine applications.

9907-055 – Electrohydraulic actuator controller designed for integration with Woodward control systems.

9907-072 – Enhanced valve servo control module with additional redundancy features.

9907-076 – Complementary control module providing advanced diagnostics and feedback capabilities.

9907-077 – Compact electrohydraulic valve control module for smaller scale engine applications.

9907-105 – Current-to-pressure converter variant optimized for higher pressure applications.

Installation Notes and Maintenance Best Practices

Prior to installing the Woodward 9907-1200, ensure that the mounting surface is sturdy and compatible with the unit’s threaded-hole configuration. Clearance should be sufficient to facilitate connections to hydraulic ports and electrical interfaces, along with space for routine inspection and servicing. Given its IP66 rating, the module is protected against dust and strong water jets, yet careful sealing of conduit entries and proper grounding remain critical steps to maintain signal integrity and protect against electromagnetic interference.

Maintenance practices include regular inspection of hydraulic connections to prevent leaks and ensure cleanliness of hydraulic fluids. The self-cleaning port design reduces contamination risks, but scheduling periodic function tests and service tool calibration is essential to verify accuracy and system responsiveness. Firmware upgrades and configuration checks should be conducted in line with manufacturer recommendations to preserve optimal performance and incorporate control enhancements.

WhatsApp: +86 16626708626

WhatsApp: +86 16626708626 Email:

Email:  Phone: +86 16626708626

Phone: +86 16626708626