Description

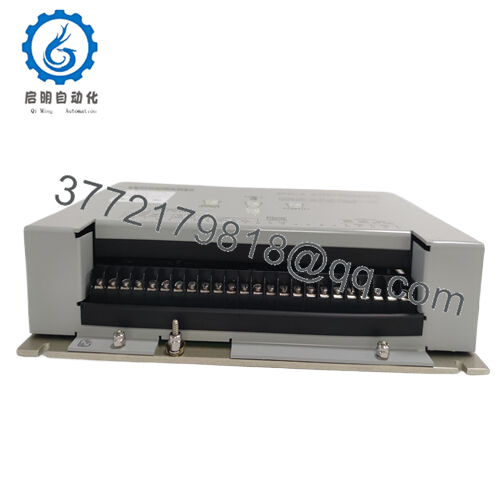

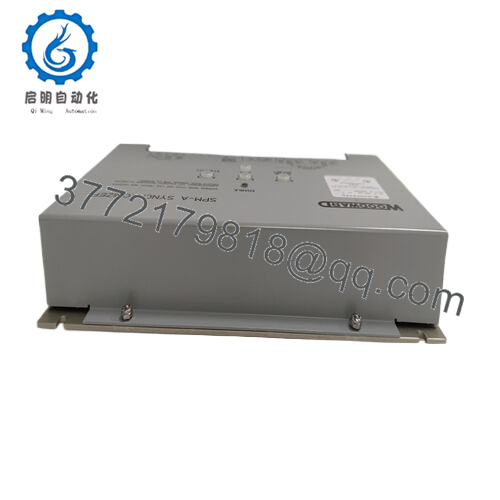

The WOODWARD 9907-028 operates as a control module, specifically designed to manage fuel flow and speed regulation in combustion engines and turbines. Positioned within the automation stack as a mid-level controller, it acts as a bridge between sensors that monitor engine parameters (such as temperature, pressure, and rotational speed) and actuators that adjust fuel valves or throttle settings. It interfaces with the broader control system via a dedicated communication bus, enabling real-time data exchange with supervisory control platforms.

9907-028

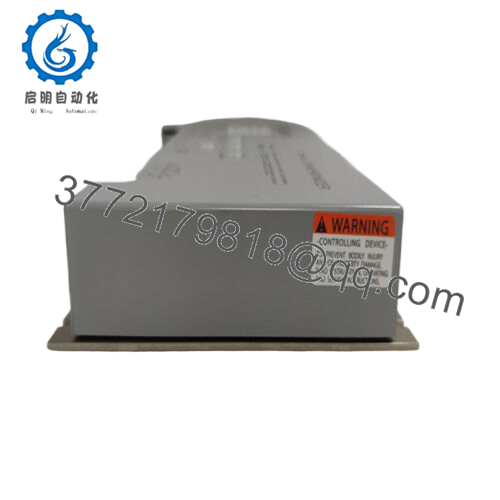

What sets the WOODWARD 9907-028 apart is its ability to process input signals quickly, applying pre-programmed control algorithms to maintain optimal engine performance even as load conditions change. It supports common industrial protocols, ensuring compatibility with a range of monitoring and data acquisition systems, and features built-in diagnostic capabilities that flag issues like sensor drift or communication failures, allowing for timely intervention. Unlike generic controllers, the WOODWARD 9907-028 is tailored to the unique demands of combustion systems, with logic optimized for smooth transitions between operating states and enhanced stability during startup and shutdown sequences.

9907-028

Technical specifications:

Model Number 9907-028

Brand Woodward

Type Engine/Turbine Control Module

Input Voltage 18-32 V DC

Operating Temp Range -40°C to +70°C

Mounting Style Panel mount with DIN rail adapter option

Dimensions 120 mm x 80 mm x 45 mm

Weight 250 g

Interface/Bus RS-485, Modbus RTU

Compliance CE, UL 508

Supported Protocols Modbus RTU, CANopen (optional)

Typical Power Draw 3.5 W

Contact Us

Phone:+86 16626708626

WeChat/WhatsApp:+86 16626708626

Email: 3772179818@qq.com

9907-028

Main features and advantages:

Opting for the WOODWARD 9907-028 brings tangible operational advantages that go beyond basic control functionality. Its advanced control algorithms ensure that engines and turbines operate at peak efficiency, reducing fuel consumption by up to 3% in steady-state conditions compared to conventional controllers. This efficiency gain translates directly to lower operational costs over the system’s lifespan, making it a cost-effective choice for long-term deployments. The module’s rapid response time—measured in milliseconds—ensures that sudden load changes are handled smoothly, preventing voltage spikes or frequency deviations that could damage connected equipment or disrupt power supply.

Another key benefit is the WOODWARD 9907-028’s ability to reduce maintenance overhead. Its self-diagnostic features continuously monitor internal components and external connections, alerting operators to potential issues before they escalate into major failures. This proactive approach to maintenance minimizes unplanned downtime, which is especially critical in industries like power generation where every minute of shutdown can result in significant revenue loss. Additionally, its modular design simplifies repairs, with field-replaceable components that reduce the time needed to restore functionality in the event of a fault.

9907-028

Application areas:

9907-028

Related products:

9907-028

Installation and maintenance:

Woodward CSC3SUWA

Woodward CSC3GM1

Woodward CSC3HUWB

Woodward 9907-1199

Woodward 8200-1302

Woodward 8440-1855 F

Woodward 5466-409

WOODWARD 8200-1302

WOODWARD 8200-1302

Woodward 8200-226

WOODWARD 8200-505

Woodward 8237 1596

Woodward 8237-2596

Woodward 8250-565

Woodward 8256-016

Woodward 8280-339

Woodward 8516-038

WOODWARD 8290-044

Woodward 8290-191

Woodward 8404-4001

Woodward 8406-113

Woodward 8407-515

Woodward 8440-1860D

Woodward 8440-2047

Woodward 8440-2050F

Woodward 8511-144

WOODWARD 8516-045

Woodward 8516-045

Woodward 8200-1508

Woodward 8520-0052

WOODWARD 8200-1300

Woodward 9907-164

WOODWARD SA-4389

Woodward 505XT 8200-1311

WOODWARD CPCII

Woodward 8270-1036

Woodward 8290-191

Woodward 8406-121

WhatsApp: +86 16626708626

WhatsApp: +86 16626708626 Email: 3772179818@qq.com

Email: 3772179818@qq.com Phone: +86 16626708626

Phone: +86 16626708626