Description

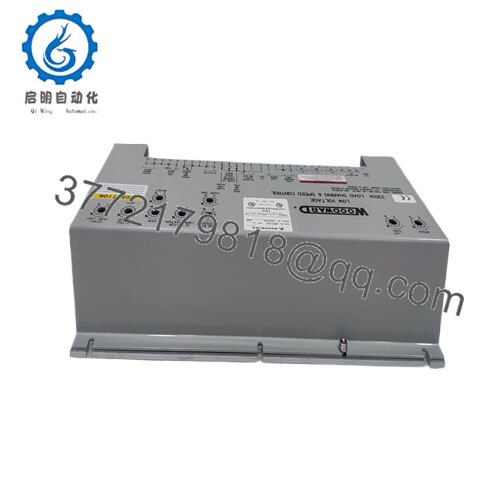

The WOODWARD 9907-018 functions as a core control component within the automation architecture, bridging the gap between sensors, actuators, and central control systems. It processes input signals from various sensors—such as pressure transducers and position encoders—using advanced control algorithms to adjust output parameters in real time, ensuring that connected machinery operates within optimal ranges. This module integrates seamlessly with common industrial buses and control platforms, supporting protocols like Modbus and Ethernet/IP, which enables efficient data exchange with SCADA systems and PLCs for centralized monitoring and control.

9907-018

A key advantage of the WOODWARD 9907-018 is its modular design, which allows for easy customization to specific application needs, whether it’s adjusting for different load capacities or integrating with legacy equipment. Additionally, it features built-in diagnostic tools that continuously monitor system health, flagging potential issues like signal degradation or component wear before they escalate into operational failures.

9907-018

Technical specifications:

Model Number 9907-018

Brand Woodward

Type Industrial Control Module

Input Voltage 24V DC ±15%

Operating Temp Range

-30°C to 75°C (-22°F to 167°F)

Mounting Style DIN Rail Mount

Dimensions 105mm x 80mm x 65mm (4.1in x 3.1in x 2.6in)

Weight 280g (9.9oz)

Interface/Bus Modbus RTU, Ethernet/IP

Compliance CE, UL 508, RoHS

Supported Protocols Modbus RTU, Ethernet/IP, Profibus (optional)

Typical Power Draw 4.2W @ 24V DC

Contact Us

Phone:+86 16626708626

WeChat/WhatsApp:+86 16626708626

Email: 3772179818@qq.com

9907-018

Main features and advantages:

Engineered for durability and performance, the WOODWARD 9907-018 delivers tangible benefits that enhance operational efficiency. Its precise control capabilities—with response times under 50 milliseconds—ensure that machinery operates within tight tolerances, reducing energy waste and maximizing output quality. The module’s rugged construction, including resistance to vibration and electromagnetic interference, ensures reliable performance in harsh industrial environments, minimizing unplanned downtime and lowering maintenance costs over the long term. For engineering teams, the WOODWARD 9907-018 simplifies system integration with its plug-and-play design, which reduces setup time by up to 30% compared to conventional control modules. Its intuitive configuration software also allows for remote adjustments, enabling engineers to fine-tune parameters without needing to be on-site, thus cutting operational overhead.

9907-018

Application areas:

The WOODWARD 9907-018 is well-suited for a range of industrial applications where precision control is critical. In manufacturing, it regulates the speed of conveyor systems and robotic arms, ensuring consistent production rates and reducing product defects. In power generation facilities, it controls auxiliary equipment like pumps and fans, maintaining optimal operating conditions for turbines and boilers. The module also finds use in oil and gas processing, where it adjusts valve positions in response to flow and pressure changes, ensuring safe and efficient hydrocarbon processing. In each of these settings, the WOODWARD 9907-018proves its value by delivering reliable performance under demanding conditions, from high-temperature factory floors to dusty industrial plants.

9907-018

Related products:

WhatsApp: +86 16626708626

WhatsApp: +86 16626708626 Email: 3772179818@qq.com

Email: 3772179818@qq.com Phone: +86 16626708626

Phone: +86 16626708626