Description

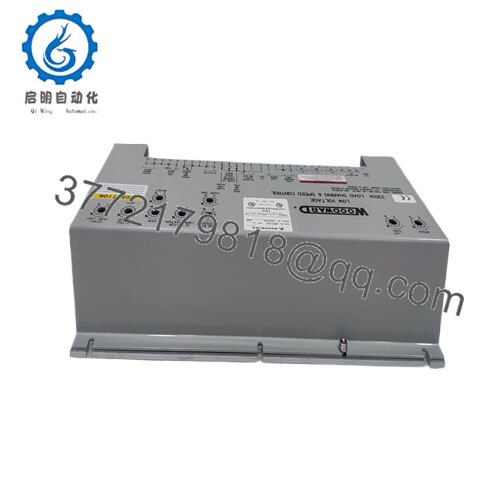

In industrial automation and power generation, where multi-generator setups must balance loads dynamically to prevent frequency drifts, overloads, or inefficient fuel burn that erode profitability and reliability, engineers often contend with controls that lack the finesse for seamless sharing or falter under variable prime mover dynamics. The Woodward 9907-018 counters this as a forward-acting, low-voltage electronic governor from the 2301A series, engineered for precise speed and load regulation in diesel, gas, or turbine-driven systems. Consider a peaking plant juggling variable grid demands or a distributed energy site syncing intermittent renewables with diesel backups—here, sluggish response or uneven kW distribution can spike emissions, accelerate actuator wear, or force manual overrides that compromise process control. This unit emerges as a high-reliability essential, where its self-contained load sensor and switch-selectable ranges ensure I/O signal stability amid EMI, vibrations, or thermal swings typical of harsh enclosures.

The Woodward 9907-018 particularly empowers retrofits of legacy analog governors, where modular integration into existing panels avoids full rewiring and extended outages. Its forward-acting architecture delivers responsive 0-200 mA commands to actuators, maintaining isochronous or droop modes without external amplifiers, which curbs the signal unreliability that hampers older setups in electrically noisy turbine halls. Fundamentally, it advances users’ aims for base loading against infinite buses or isolated multi-unit islands, trimming the calibration cycles in commissioning. For plant operators or integrators prioritizing uptime in hybrid power environments, the Woodward 9907-018 provides a CE-compliant backbone that converts load-sharing complexities into streamlined efficiency, fortifying industrial automation where every watt counts toward sustainable output.

The Woodward 9907-018 anchors the speed/load control layer in the 2301A ecosystem, interfacing with prime movers via magnetic pickups or 4-20 mA process signals to modulate actuator outputs through PID-tuned loops, ensuring frequency hold within 0.25% under load steps. It plugs into backplane or standalone panels, processing CT inputs for droop calculations (1-5% adjustable) and relaying discrete alarms for overspeed or low-oil scenarios, which integrate via analog ties to SCADA for broader oversight. In paralleled configurations, its load-sharing logic—via dedicated bias lines—equalizes kW across units without a master controller, supporting up to 16 gensets on isolated buses while accommodating APTL accessories for import/export limits.

What engineers value is its diagnostics simplicity; potentiometers allow field tweaks to gain, ramp times (up to 30 seconds acceleration), or idle setpoints, with LED indicators flagging faults like sensor drift for quick isolation. Positioned in the I/O stack above field transducers but below DCS logic, the Woodward 9907-018 employs optical isolation to buffer against RFI, and its low-voltage design (20-40 Vdc) pairs with 24 Vdc rails common in enclosures. Redundancy options include dual-sensor voting for critical turbines, and compatibility with Woodward’s EG/PB actuators streamlines drop-ins. This adaptability shines in process control expansions—scale from single-unit isochronous to multi-droop sharing sans reconfiguration—making it a pragmatic fit for evolving architectures where responsive governance hinges on intuitive, interference-hardened hardware.

- 9907-018

| Specification | Details |

|---|---|

| Model Number | 9907-018 |

| Brand | Woodward |

| Type | Load Sharing/Speed Control |

| Input Voltage | 20-40 Vdc |

| Operating Temp Range | -40°C to +85°C |

| Mounting Style | Panel Mount |

| Dimensions | 15.25 x 7.125 x 2.5 in |

| Weight | 0.8 kg |

| Interface/Bus | Analog (4-20 mA, 1-5 Vdc) |

| Compliance | CE (89/336/EEC, 73/23/EEC) |

| Supported Protocols | N/A (Analog) |

| Typical Power Draw | 8 W |

Harnessing the Woodward 9907-018 instills reliability that navigates prime mover quirks, its shielded chassis and conformal coatings preserving loop accuracy through dust-laden cycles or humidity spikes to avert hunts that idle generators—yielding amplified MTBF and deferred overhauls that align with lean maintenance regimes in power ops.

Commissioning burdens ease substantially, as switchable speed bands (500-4500 Hz) preset for common engines let teams verify sharing on simulators pre-install, compressing field proofs from shifts to hours and easing integration in OEM skids where terminal standardization skips harness redraws. This dials back engineering tolls, particularly in renewables hybrids where its process input overrides enable seamless solar curtailment.

Maintenance orients toward prevention; the unit’s self-diagnostics latch faults for post-run audits, folding into quarterly pot checks to sustain droop linearity without disassembly, while automatic fuel limiting at startup curbs thermal shocks that hike NOx. In aggregate, the Woodward 9907-018 cultivates enduring performance by optimizing ramp profiles that soften load swings, trimming fuel by 2-5% in baseload runs and meeting emissions tiers, all while its analog core sidesteps firmware glitches for a steadfast ally in regulated process control landscapes.

The Woodward 9907-018 governs diesel gensets in utility peaking stations, where it equalizes loads across banks for grid response, delivering high-reliability I/O amid harmonic noise in high-cycle process control setups with unerring frequency stability. In gas turbine co-gen plants, it handles steam bypass modulation under variable exports, enduring thermal gradients while securing critical system uptime via precise droop sharing.

For backup arrays in data facilities, the control regulates gasoline backups for seamless islanding, providing robust signal conditioning against EMI bursts to uphold voltage within 1% during transfers.

9907-019 – Reverse-acting variant for legacy actuator compatibility in turbine retrofits

9907-014 – High-voltage counterpart (90-150 Vdc) for robust electrical systems

9905-010 – Isochronous-only model for single-unit constant-speed applications

9907-167 – Enhanced digital successor with HMI for advanced trending

2301A-015-018 – Load sensor add-on for isolated bus expansions

9907-029 – Voltage-matching synchronizer companion for grid-tie precision

8237-1001 – Basic analog predecessor for economical upgrades

9905-468 – Multi-unit sharing module for scaled paralleling networks

When prepping the Woodward 9907-018 for rollout, confirm actuator coil resistance (10-500 ohms) against its 0-200 mA drive to preclude overcurrent trips, and gauge enclosure slots for its 15.25-inch length—tight fits throttle airflow in warm turbine bays. Stabilize the 20-40 Vdc rail with decoupling caps over 50 V peaks that could reset the PCB, and dial initial pots per engine inertia from Woodward’s curves to mute startup overshoots. If load-sharing, verify CT polarity upfront, as reversals skew bias and demand full recalibration.

Sustained care emphasizes annual LED scans for stability cues, paired with terminal audits for vibration-loosened sets in genset mounts—a torque wrench to 12 in-lbs restores grip sans stripping. Biannual ramp tests under no-load simulate steps, logging gains to preempt drift from pot wear, and in droop modes, cross-check sharing equity quarterly by cycling units offline. These distilled practices, pulled from fleet histories, nurture the Woodward 9907-018‘s poise with measured inputs, preserving edge without workflow drags.

WhatsApp: +86 16626708626

WhatsApp: +86 16626708626 Email:

Email:  Phone: +86 16626708626

Phone: +86 16626708626