Description

In industrial automation and power generation, where accurate real-time monitoring of electrical parameters is crucial to prevent overloads, inefficiencies, or undetected faults that could cascade into system-wide disruptions, engineers frequently encounter challenges with transducers that introduce measurement errors due to waveform distortions or environmental noise. The Woodward 8444-1019F meets this need as a true RMS measuring transducer from the UMT1 series, providing precise conversion of AC voltage, current, and frequency into proportional DC or analog outputs for seamless integration into control systems. Envision a marine propulsion genset or a utility substation where non-sinusoidal loads from variable frequency drives create harmonic distortions—here, conventional averaging transducers might misreport values, leading to improper load sharing, protective relay misfires, or skewed process control decisions. This unit becomes essential in those high-reliability scenarios, where robust I/O signal conditioning handles distorted waveforms up to the 31st harmonic, ensuring data integrity amid vibrations, humidity, or EMI prevalent in industrial environments. It promotes system stability by delivering scaled outputs that feed directly into PLCs or DCS platforms, often reducing the need for additional signal conditioners that complicate setups.

The Woodward 8444-1019F is particularly valuable during expansions of legacy monitoring panels, where modular integration allows for plug-compatible upgrades without extensive recalibration. Its true RMS calculation—based on thermal equivalent heating—guarantees accuracy across a broad range of load types, countering the signal unreliability that afflicts peak-reading alternatives in electrically noisy turbine or genset applications. At its core, this transducer supports users’ objectives for compliant metering in line with IEC 60688 standards, minimizing the validation efforts in commissioning phases. For control system designers or maintenance leads focused on resilient power management, the Woodward 8444-1019F offers a high-reliability foundation that transforms measurement uncertainties into trustworthy insights, enhancing industrial automation where precise parameter tracking underpins safe, efficient operations.

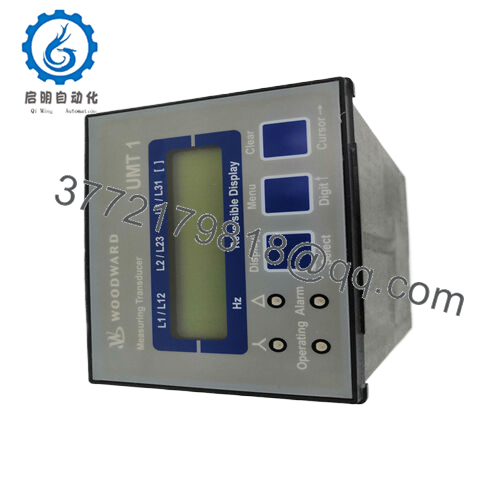

The Woodward 8444-1019F slots into the sensing layer of the automation stack as part of the UMT1 family, converting single or three-phase AC inputs—voltage up to 150 Vac or current via 5A CTs—into isolated DC analogs (0-10 V or 4-20 mA) for parameters like V, I, or Hz, displayed on its integrated two-line LCD for local verification. It mounts in standard DIN enclosures, wiring directly to field busbars or transformers, and outputs to analog loops that tie into easYgen controllers or SCADA gateways, enabling threshold-based alarms or trending without digital overhead. In a typical genset panel, it processes 50/60 Hz signals with 0.5% accuracy, supporting auxiliary 24 Vac power for low-voltage resilience, while built-in diagnostics flag open circuits or over-range via relay contacts for immediate operator cues.

Engineers appreciate its interaction flexibility; the transducer’s scalable outputs adapt to control platforms via jumper-selectable ranges, and its galvanic isolation (up to 2.5 kV) buffers against ground potentials in multi-grounded I/O architectures. Positioned upstream of the control logic but downstream of raw metering, the Woodward 8444-1019F enhances signal reliability by filtering transients, compatible with protocols through analog passthrough to Modbus converters if needed. For redundancy, it pairs in dual-channel setups for voting on critical feeds, and the F revision’s refined firmware improves harmonic rejection for modern inverter-heavy loads. This makes it a straightforward embed in process control hierarchies—from substation monitoring to engine test stands—where it delivers conditioned data that streamlines loop tuning without introducing latency or noise susceptibility.

- 8444-1019F

| Specification | Details |

|---|---|

| Model Number | 8444-1019F |

| Brand | Woodward |

| Type | True RMS Measuring Transducer |

| Input Voltage | 24 Vac auxiliary; 57-150 Vac measurement |

| Operating Temp Range | -20°C to +70°C |

| Mounting Style | DIN Rail/Panel |

| Dimensions | 90 x 45 x 110 mm |

| Weight | 0.3 kg |

| Interface/Bus | Analog (0-10 V, 4-20 mA) |

| Compliance | CE, UL (E231544), IEC 60688 |

| Supported Protocols | N/A (Analog) |

| Typical Power Draw | 5 VA |

Selecting the Woodward 8444-1019F equips your monitoring setup with precision that endures waveform anomalies and site stressors, its true RMS core maintaining 0.2% error margins through distorted cycles to sidestep false trips that halt production—fostering extended calibration intervals and confidence in data-driven decisions for stretched industrial timelines.

From a deployment angle, its jumper-configurable ranges align with diverse CT/PT setups sans custom scaling, empowering teams to prototype in labs before field cuts and trimming integration hurdles in OEM assemblies where terminal universality skips adapter fab. This eases engineering strains, especially in renewables-tied grids where harmonic spikes from inverters could otherwise demand frequent re-benches. Maintenance evolves to be insight-led; the LCD’s live readings plus relay flags spotlight drift early, folding into semiannual audits to validate against master meters without full-system teardowns.

In the larger picture, the Woodward 8444-1019F bolsters long-term performance by enabling predictive analytics on trends like PF shifts, which optimize load flows and curb energy waste by 1-3% in baseload runs, all while its compact form factors support dense panels that cut enclosure footprints. This not only lightens expansion costs but also aligns with compliance mandates for accurate billing or protection, rendering it a shrewd pick for automation pros navigating the shift to electrified, variable-source power landscapes.

The Woodward 8444-1019F anchors genset metering in marine auxiliaries, where it tracks distorted currents from propulsion loads, supplying high-reliability I/O for protective relaying in humid, salt-corroded process control environments with steadfast harmonic immunity. In utility substations, it converts bus voltages for SCADA feeds, handling fast transients from switching ops to ensure critical system uptime amid urban EMI densities.

For wind farm inverters, the transducer monitors output currents under non-linear waveforms, delivering precise analogs for curtailment logic in remote, wind-battered setups that demand unerring signal fidelity.

8444-1019 – Base revision without F firmware for legacy analog loops

8444-1020 – Three-phase variant for balanced load monitoring in delta systems

8444-1074 – Load Share Gateway companion for multi-unit analog ties

8444-1091 – ProTech-III module for overspeed protection integration

8444-3003 – Enhanced display model with expanded parameter logging

8237-1001 – Legacy UMT predecessor for basic RMS upgrades

9907-029 – Synchronizer add-on for paralleling with measured sync

8440-1849 – easYgen controller alternative for digital genset oversight

Before commissioning the Woodward 8444-1019F, match your PT/CT burdens to its 0.1 VA max draw to avoid attenuation—overloads skew readings low—and confirm DIN slot depth for its 110 mm height, as overhangs crimp heat paths in stacked vaults. Secure auxiliary 24 Vac with fusing under 0.5 A to block surges over 30 Vac that latch outputs, and jumper ranges per site harmonics via Woodward’s selector guide to baseline against test waveforms. If tying to PLC analogs, verify loop impedance under 500 ohms, lest voltage drops warp the 4-20 mA span.

Ongoing stewardship hinges on quarterly LCD checks for steady displays under no-load, twinned with terminal probes for continuity in dusty housings—a contact cleaner spray restores without residue. Annual bench verifications against calibrated sources tune zero/full-scale offsets, archiving variances to gauge aging on sense bridges. In three-wire installs, rotate CT phases yearly to even wear, isolating power segments first to dodge induced voltages. These honed steps, sourced from panel logs, sustain the Woodward 8444-1019F‘s exactitude with light touch.

WhatsApp: +86 16626708626

WhatsApp: +86 16626708626 Email:

Email:  Phone: +86 16626708626

Phone: +86 16626708626