Description

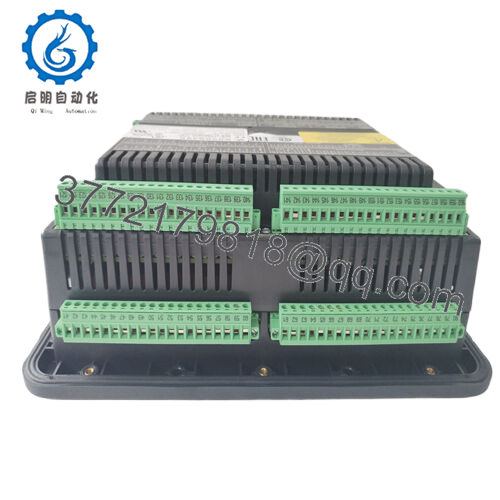

The Woodward 8440-1936 is a genset controller from the easYgen-3500 series, designed specifically for generator set control and protection with advanced parallel operation capabilities. This product finds extensive use in power generation facilities, commercial buildings, and industrial plants where reliable power management, automatic start/stop functions, and synchronized operation of multiple generator sets are essential. The 8440-1936 is engineered to manage complex breaker control, load sharing, and power quality tasks, making it highly applicable to control systems requiring precise synchronization and adaptive load distribution between multiple gensets and mains grids.

- 8440-1936

Functionally, the 8440-1936 acts as the control hub for a genset, capable of automatic, manual, or remote operation modes. It supports open and closed transition breaker control, run-up synchronization, and load-dependent start/stop for up to 32 units operating in parallel. The controller is designed to work seamlessly with Woodward’s LS-5 series controllers and supports communication protocols like CANopen and J1939 for engine control units, enhancing integration and monitoring. Its modular software architecture enables rapid configuration, flexible alarm management, and support for applications ranging from standby power and peak shaving to distributed generation and cogeneration (CHP). The front panel mounting and color LCD display with softkey navigation provide intuitive local control and diagnostics.

The 8440-1936 module supports a 12/24 VDC power supply (8 to 40 VDC) and operates reliably across a temperature range suitable for industrial environments. It features up to 23 discrete alarm inputs, configurable discrete outputs, and multiple analog and digital I/O connections for comprehensive genset and breaker interface. The advanced control algorithms include freely configurable PID controllers for various control purposes such as voltage and frequency management, reactive power regulation, and cylinder temperature monitoring. The device supports synchronization and load sharing with multiple parallel units, allowing scalable installation across complex electrical grids.

| Parameter | Value |

|---|---|

| Model | 8440-1936 |

| Brand | Woodward |

| Product Type | easYgen-3500 Genset Controller |

| Power Supply | 12/24 V DC (8 to 40 VDC) |

| Operating Temperature | -20°C to 70°C |

| Discrete Inputs | Up to 23 discrete alarm inputs |

| Discrete Outputs | Configurable (max 22) |

| Analog Inputs | Freely scalable isolated analog I/O |

| Display | Color LCD graphical display with softkeys |

| Communication Protocols | CANopen, J1939, Ethernet/IP |

| Parallel Operation | Up to 32 gensets |

| Breaker Control | Open/closed transitions, GGB control |

| Certifications | CE Mark, others as applicable |

| Mounting | Front panel mounting |

Related models in the Woodward easYgen family include the 8440-1935 (similar controller with different current transformer input), 8440-1943 (another 3500-series controller with broader input/output capabilities) and the 8440-1956 (cabinet back mounting variant designed without a local display). These options allow system designers to customize control strategies according to plant size, installation requirements, and monitoring preferences.

Installing the Woodward 8440-1936 requires a suitable front panel cutout with environmental sealing per IP54 or IP66 depending on application needs. Proper wiring of the discrete and analog inputs/outputs must follow manufacturer guidelines to maintain signal integrity and EMI immunity. The front panel interface facilitates on-site configuration and status monitoring, while remote access capabilities enable offsite diagnostics and control.

Maintenance involves checking terminal blocks and cables, verifying status LEDs, and running diagnostic procedures through the controller’s software interface. Firmware upgrades and parameter backups can be managed via CAN, Ethernet, or serial interfaces, ensuring that the controller remains up to date with evolving operational demands and regulatory requirements.

WhatsApp: +86 16626708626

WhatsApp: +86 16626708626 Email:

Email:  Phone: +86 16626708626

Phone: +86 16626708626