Description

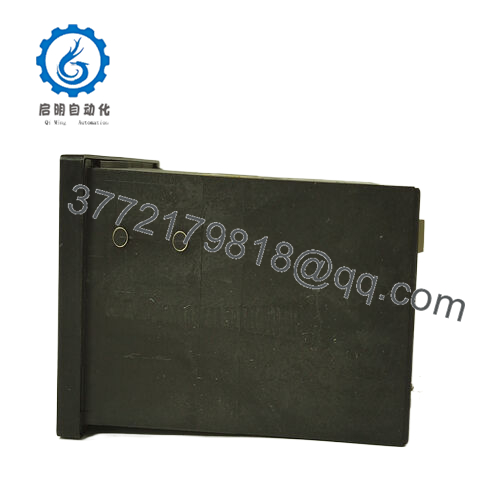

The Woodward 8440-1713 is a critical component widely used in industrial automation systems that demand precise motion and synchronization control, especially in power generation and heavy machinery. It finds applications in controlling the speed, position, and torque of servo motors in processes such as turbine synchronization, generator control, and engine monitoring. Power plants, manufacturing industries, and energy sectors rely on this advanced digital servo drive module to ensure smooth, accurate motor operation essential for stability and efficiency.

- 8440-1713

Industries benefit from the 8440-1713 where precision and reliability are paramount — synchronizing generators or controlling turbine speed requires highly responsive control modules capable of handling dynamic loads and rapid adjustments. The module overcomes challenges related to noise interference, harsh industrial environments, and complex signal coordination by delivering consistent performance in real-time. This capability makes it invaluable in scenarios where system uptime impacts safety and production continuity.

Product Introduction and Positioning

The Woodward 8440-1713 is a digital servo drive module designed to control servo motors by managing position, speed, and torque. It is embedded in Woodward’s automations solutions, specializing in turbine and generator control systems. This module integrates seamlessly into control architectures that require precise and reliable servo feedback and command execution, forming a core part of motion control loops in critical industrial applications.

As part of Woodward’s digital control product family, the 8440-1713 supports flexible control modes and network communication interfaces, making it adaptable to various system needs. It is positioned as an essential hardware piece for engineers and system integrators seeking a robust and configurable digital servo drive solution that offers enhanced accuracy and protection in demanding plant environments.

Key Technical Features and Functional Benefits

The Woodward 8440-1713 offers multiple control modes including position, speed, and torque control, providing versatility that meets diverse operational requirements. It employs advanced digital technology to deliver high-accuracy feedback and stable motor control while integrating protection functions such as overcurrent, overvoltage, and thermal safeguards to prevent damage and extend service life.

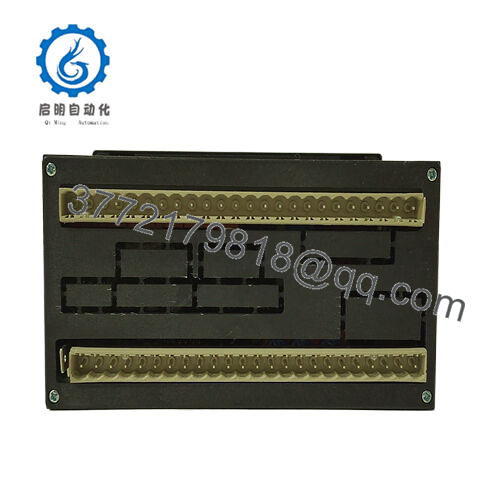

Its compatibility with feedback devices like encoders ensures real-time monitoring and adjustment, enabling rapid response to load changes or process fluctuations. Communication options including Ethernet, RS-232, RS-485, and CAN bus facilitate efficient data exchange and integration into distributed control systems or supervisory networks.

Designed with an industrial-grade rugged housing, the module operates reliably across a wide temperature range (-40 to +85 °C) and withstands electrical noise and vibration typical of automation environments. Compact and lightweight, the 8440-1713 also simplifies system layout and installation.

Detailed Technical Specifications

| Parameter | Value |

|---|---|

| Model | 8440-1713 |

| Brand | Woodward |

| Product Type | Digital Servo Drive Module |

| Control Modes | Position, Speed, Torque |

| Input Voltage Range | 12 to 48 V DC |

| Output Voltage Range | 0 to 10 V DC |

| Output Current Range | 0 to 20 mA DC |

| Operating Temperature | -40 to +85 °C |

| Dimensions (WxHxD) | 133 x 114 x 64 mm (5.25” x 4.5” x 2.5”) |

| Weight | 0.45 kg (1 lb) |

| Communication Interfaces | Ethernet, RS-232, RS-485, CAN bus |

| Protection Features | Overcurrent, Overvoltage, Overheating |

Related Modules or Compatible Units

8440-2050 – Digital speed controller for broader engine and turbine control applications.

9907-018 – Load sharing and speed control actuator module within Woodward turbine control lines.

5466-258 – Position controller module compatible with digital servo drives.

8200-226 – Backup controller module designed for redundant control architectures.

9907-167 – Advanced control module offering integrated diagnostics and enhanced tuning options.

Installation Notes and Maintenance Best Practices

The Woodward 8440-1713 should be installed in control panels with adequate ventilation and space to allow for wiring access and heat dissipation. Proper shielding and grounding of signal cables are critical to ensure noise immunity and stable signal transmission in electrically noisy environments. The module should be mounted securely to minimize vibration impact while maintaining environmental protection as per industrial standards.

Routine maintenance includes periodic inspection of electrical connections for corrosion or looseness and verification of feedback device alignment and functionality. Utilizing the configuration software included with the module, engineers should regularly update firmware and recalibrate parameters to maintain optimal performance. Monitoring diagnostic signals helps predict potential issues, minimizing unplanned downtime.

WhatsApp: +86 16626708626

WhatsApp: +86 16626708626 Email:

Email:  Phone: +86 16626708626

Phone: +86 16626708626