Description

Product Model: 8440-1706

Product Brand: Woodward

Product Series: SPM-D11 / LSXR

Product Features:

- Combines synchronization, load sharing, phase/voltage matching, and generator protection

- Soft unload, slip-frequency or phase matching modes, relay outputs for protection and control

- Discrete and measured inputs including generator voltage, bus voltage, current, synchronizer logic

- Compact form factor (approx 144 × 72 × 122 mm, ~0.8 kg)

- 8440-1706

Applications & Industry Context

When bringing multiple generator sets online in industrial, commercial, or renewable installations, synchronization and load sharing are essential. The 8440-1706 sits squarely in that domain: it’s a synchronizer and paralleling controller, enabling phase matching, voltage matching, and coordinated load control among generators and with the utility grid.

You’ll find the 8440-1706 in backup power plants, data centers, microgrids, distributed energy systems, and utility substations. In a scenario where multiple gensets run in parallel, this module ensures that each generator is matched in voltage, phase angle, and frequency before closing a breaker. Once synchronized, it controls load allocation (isochronous or droop control) and provides protective logic like soft unload, slip-frequency synchronization, and synchronization monitoring.

In retrofit systems, operators often replace older analog synchronizers with the 8440-1706 to gain more flexibility, programmable logic, and integrating with SCADA or CAN / Modbus systems. The presence of soft unload and slip frequency modes makes it robust against transient conditions or mismatches. When running remote or off-grid, precise synchronization control provided by this model can help prevent misoperation, reduce mechanical stress, and improve system stability.

In microgrid or islanded operation, where load and generation fluctuate, the 8440-1706 becomes a central brain to manage transitions, shedding, or reconnecting to main grid by handling synchronization, load matching, and protective interlocks.

Product Role & System Integration

The 8440-1706 is not a full engine governor or voltage regulator by itself; rather, it is a synchronizer / parallel control module. Its domain lies in coordinating multiple generation sources, ensuring safe breaker closure, balancing loads, and supervising parallel operations.

Internally, it measures generator outputs (voltage, current), bus voltages, phase relationships, and uses discrete inputs/trip logic to decide when to allow synchronizing. It issues outputs (often via relays) to close breakers, initiate load transfers, or command soft unload. It can operate in phase-matching or slip-frequency synchronization modes, depending on system design.

The 8440-1706 also supports soft unload or gradual load shedding to prevent abrupt transfer stress, and provides protective features like synchronization checks and time monitoring.

Typically, the synchronizer is coupled with genset controllers (e.g. Woodward easYgen, or engine control modules) and interacts over analog/discrete signals or communication protocols. In many setups, the 8440-1706 issues relay control to the synchronizer logic or power breakers, while the engine controller adjusts speed or excitation to comply with the synchronization commands.

From a system architecture view, you’ll often see: generator + AVR + engine control → synchronizer (8440-1706) → breaker logic / load share → utility or bus. The synchronizer may also feed back status to SCADA or supervisory controllers for visibility and alarms.

Technical Features & Benefits

Let’s highlight the key attributes of the 8440-1706 and why it remains a choice in many parallel generator systems.

Phase Matching & Synchronizing Modes

One strength is the flexibility to operate either in slip-frequency mode (where frequencies are slightly offset until alignment) or phase matching / voltage matching mode, depending on system requirements. Operators can choose the mode that suits their synchronization strategy.

Soft Unload & Load Control

The module offers soft unload capability, meaning when a generator is being taken off line, it gradually relieves load rather than abrupt removal—this avoids system shocks. It also supports real power control, reactive power / power factor control, and can limit power or adjust setpoints.

Protective and Supervisory Logic

The 8440-1706 includes synchronization checks, synchronization time monitoring, and interlocks for safety. It monitors voltage, current, and has trip/discrete inputs for protection. In many datasheet references, functions like “First-Out Trip Indication (5 total trip inputs), Critical Speed Avoidance, Auto Start Sequences, Zero Speed Detection, Peak Speed Indication, Isochronous Load Sharing” are cited.

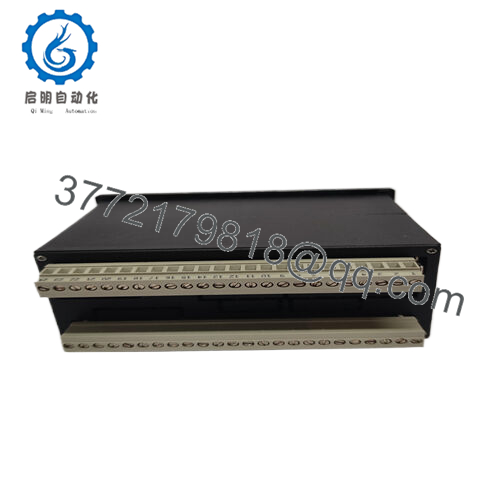

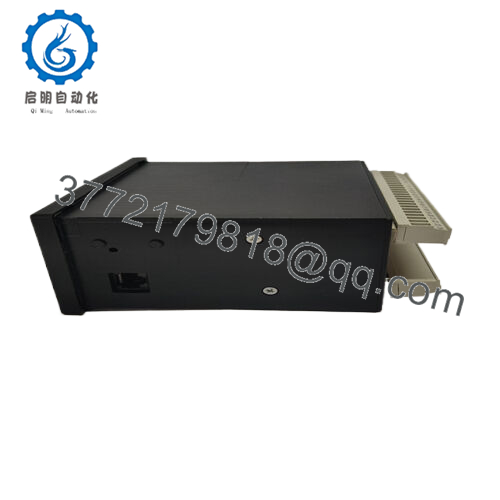

Compact Form Factor & Weight

Compared to bulky legacy units, the 8440-1706 is relatively compact: approximately 144 × 72 × 122 mm and weight around 0.8 kg. Its enclosure is sized for panel or rack mounting and can slot into parallel control boards or switchgear compartments.

Dual Display & Diagnostics

The unit includes an integrated two-line LCD display for diagnostics, alarm indicators, and real-time status. The display helps technicians observe synchronization conditions, error states, or control parameters on site without extra tools.

Voltage / Current Sensing Capability

As a synchronizer, it supports measuring generator and bus voltages and currents. Some references state it supports dual generator voltage, bus voltage, and one generator current channel. This capability enables the module to calculate true power, real-time load sharing, and fault detection.

Retrofit & Drop-In Replacement

Many providers market the 8440-1706 as a drop-in or replacement for legacy synchronizer modules. This helps in modernization projects where one wants to upgrade synchronization logic without rewiring major swaths of protection or breaker logic.

In practice, operators often report smoother transitions, fewer mis-sync events, and better load control when upgrading to a modern synchronizer like the 8440-1706 due to its programmable logic and protective monitoring.

Installation & Maintenance Insights

Proper installation and maintenance of the 8440-1706 is key to its reliable long-term performance.

Mounting & Thermal Considerations

Mount this unit in a control cabinet with adequate ventilation, away from excessive heat sources or direct sunlight. The compact housing means heat dissipation is moderate, but don’t stack heat-generating units directly overhead. Use proper mounting rails or fixed brackets to avoid vibration stress.

Power & Signal Wiring

The 8440-1706 is powered typically with 12/24 V DC (check the variant). Ensure stable supply with protection (fuses, transient suppression). Signal wiring for voltage, current, phase reference, breaker control, and discrete inputs should use shielded, twisted pairing and appropriate isolation. Keep high-voltage or power wiring separated from control wiring.

Synchronization Wiring & Logic

Ensure phase reference wiring (voltage sensing) is reliable and has correct phasing. Use proper CTs (current transformers) with matching ratios and accurate alignment. Relay outputs used to close breakers or send logic signals must be rated and wired correctly. Observe dead bus or breaker sequencing logic to prevent unsafe breaker closing.

Commissioning Steps

- Start with verifying all sensing inputs (volts, current, CT polarity) and discrete inputs/trip logic

- Confirm the LCD or front display is showing expected values

- Use the module’s configuration settings to select synchronization method (slip or phase)

- Test synchronizing behavior in manual or simulation mode before connecting to live breakers

- Verify soft unload, load sharing logic, and protection/trip logic

- Monitor synchronization times and alarms during commissioning

Routine Maintenance

Inspect wiring terminals for tightness and oxidation. Clean cabinet internals, remove dust or debris. Periodically exercise relays to avoid sticking. Monitor alarm logs or event history via the display. Occasionally validate voltage/current calibrations against known standards.

Keep spare fuses, connectors, and a hot spare 8440-1706 if possible—synchronizer logic is critical in parallel generation, and downtime can cascade.

Firmware / Config Updates

If the module supports firmware updates or parameter patches, coordinate version compatibility with the rest of the control system. Always bench-test firmware changes before deploying to live operation.

Technical Specifications Table

| Parameter | Value / Description |

|---|---|

| Module Type | Generator Synchronizer / Paralleling Control (SPM-D11 / LSXR) |

| Dimensions | ~144 × 72 × 122 mm |

| Weight | ~0.8 kg (≈ 800 g) |

| Power Supply | 12/24 V DC (standard variant) |

| Measurement Inputs | Generator voltage, bus voltage (2 phases), current (1 generator) |

| Synchronization Modes | Phase matching, slip-frequency mode |

| Soft Unload | Supported (gradual load removal) |

| Protective Logic | Synchronization checks, time monitoring, interlocks, trips |

| Relay Outputs / Discretes | Relay outputs for breaker control, discrete trip / logic inputs |

| Display | 2-line LCD diagnostic display |

| Operating Temperature | Typical industrial range (user to confirm variant) |

| Mounting | Panel or rack mounting in control cabinet |

| Application Features | True RMS sensing, load sharing, phase/voltage match, auto sync, limiting, soft unload, trips |

| Compatibility | Often drop-in for legacy synchronizer modules |

(Note: Because official Woodward published datasheet for 8440-1706 is scarce, some values are drawn from distributor listings. Users should verify with actual product documentation.)

Related Models & Migration Paths

Here are a few sibling or alternative modules related to 8440-1706:

- 8440-1706 B — variant with extended firmware or improved interface in the same control family

- 8440-1546 / 8440-1809 — other modules in the Woodward easYgen / SPM series used in synchronization or control roles

- SPM-D2 family — newer replacement synchronizer modules which may offer enhanced features, updated interfaces, or drop-in compatibility for legacy SPM-D11 units (often marketed as modern successor)

- Woodward easYgen controllers — often act as the host generator controller with synchronization logic that may complement or replace external modules

- Other paralleling / synchronization modules from vendors (e.g. from ABB, Basler, or Siemens) — used in non-Woodward systems or hybrid systems

When planning upgrades or replacements, consider whether your control architecture can internalize sync logic (e.g. via genset controller) or whether retaining the 8440-1706 (or its successor) gives more modular flexibility.

WhatsApp: +86 16626708626

WhatsApp: +86 16626708626 Email:

Email:  Phone: +86 16626708626

Phone: +86 16626708626