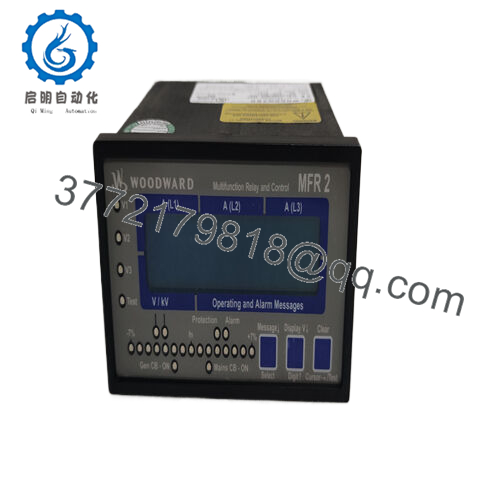

Description

In industrial automation and power generation, where small-scale gensets must deliver reliable standalone or paralleled operation without the overhead of oversized controllers, engineers often face integration bottlenecks with units that overcomplicate simple emergency or prime power setups. The Woodward 8440-1546H cuts through this as a compact genset control module from the easYgen-1500 series, tailored for single-unit control with engine management, protection, and basic synchronization in space-constrained panels. Think of a remote telecom shelter firing up a diesel backup during a blackout or a construction site genset stabilizing loads amid fluctuating demands—here, sluggish response times or unreliable metering can lead to voltage sags, fuel overruns, or unintended shutdowns. This module is pivotal in such high-reliability niches, where streamlined I/O signal processing counters dust, moisture, and voltage transients typical of process control in off-grid applications. It bolsters system stability by fusing governor control, AVR interfacing, and fault detection into one unit, often sidestepping add-on modules that inflate costs and complexity.

The Woodward 8440-1546H stands out in upgrades of legacy manual-start systems, where modular integration allows drop-in replacement without panel redesigns. Its H variant emphasizes hardened I/O for harsher environs, preserving signal reliability on parameters like speed, oil pressure, and alternator excitation even amid electrical noise or thermal spikes. Core to its appeal is empowering users toward goals like automated cranking under 5 seconds or precise frequency hold without constant tweaks, easing the debug load in field deployments. For OEMs or maintainers handling distributed power in renewables-tied setups, the Woodward 8440-1546H furnishes a high-reliability entry point that marries affordability with robust industrial automation fundamentals, transforming routine genset oversight into effortless efficiency.

The Woodward 8440-1546H embeds in the easYgen-1500 framework, claiming the genset control slot in the automation stack to handle start/stop logic, speed regulation via PID loops, and protective relaying from sensors like crankcase pressure or coolant temps. It accepts analog inputs from magnetic pickups or 4-20 mA transmitters, outputting to electronic governors and contactors while monitoring alternator via PTs for over/under voltage trips. In standalone mode, it operates independently, but the H model’s enhanced discretes support basic paralleling cues if scaled later, linking via RS-485 for peer data in small clusters—positioning it adeptly in the I/O flow, above raw field ties but feeding Modbus to HMI or PLC layers.

User-friendly diagnostics include a real-time clock for 50-event logging and LED fault indicators that cue issues like low fuel before escalation, with configurable setpoints for custom alarms. Redundancy isn’t native but pairs well in hot-standby via external relays, and its J1939 compatibility meshes with modern ECUs for throttle commands. DIN-rail mounted in enclosures, the Woodward 8440-1546H conditions signals against EMI with optical isolation, letting engineers adjust ramp rates or idle speeds through Woodward’s ToolKit PC interface without disassembly. This adaptability suits diverse process control setups—from base-load priming to peak shaving—where its low-profile design trims wiring runs, fostering quick ties into existing architectures without taxing the bus.

| Specification | Details |

|---|---|

| Model Number | 8440-1546H |

| Brand | Woodward |

| Type | Compact Genset Controller |

| Input Voltage | 12/24 Vdc (8-36 Vdc) |

| Operating Temp Range | -20°C to +70°C |

| Mounting Style | DIN Rail/Panel |

| Dimensions | 160 x 160 x 120 mm |

| Weight | 0.8 kg |

| Interface/Bus | RS-485, J1939 |

| Compliance | CE, UL, IEC 61000 |

| Supported Protocols | Modbus RTU |

| Typical Power Draw | 6 W |

Integrating the Woodward 8440-1546H instills reliability that weathers site-specific grit, its sealed relays and conformal coating holding firm against condensation or particulates to lock in metering precision across thousands of cycles—yielding fewer callouts and deferred replacements that stretch budgets in lean industrial ops.

Setup streamlines notably, with factory-tuned defaults for common diesel profiles that slash parameter hunts, enabling techs to verify cranking logic on a laptop in minutes rather than hours of bench testing. This eases engineering overhead in OEM lines, where standardized footprints mate with off-the-shelf cabinets sans adapters. Maintenance tilts toward foresight; the event buffer flags recurring faults like battery drain for preemptive swaps, aligning checks with routine genset services to sideline surprises during actual loads.

- 8440-1546H

Broadly, the Woodward 8440-1546H eases scalability in evolving power mixes, accepting analog overrides for solar tie-ins or load banks without firmware flashes, which curbs retrofit friction. This foresight not only tempers long-term costs through adaptive thresholds that fine-tune fuel maps but also upholds performance consistency, curbing excursions that hike wear or emissions in regulated process control realms.

The Woodward 8440-1546H drives telecom backups in cell towers, automating diesel cranks for seamless handover during grid dips, offering high-reliability I/O to track battery banks in remote, weather-beaten process control spots with unwavering signal fidelity. In construction site prime power, it regulates portable gensets for tool runs, enduring dust and jolts while ensuring critical system uptime via swift fault clears under variable loads.

For agricultural irrigation pumps, the module oversees engine sequencing in off-grid fields, delivering robust metering against humidity for consistent pressure hold in extended duty cycles.

8440-1546 – Base model without hardened I/O for milder indoor applications

8440-1547 – Display-equipped variant for on-panel monitoring in operator-accessible zones

8440-2085 – XT upgrade with expanded relays for interlock-intensive setups

8440-1817 – 5A CT version for high-current alternator sensing

8440-1706 – SPM-D11 synchronizer companion for basic paralleling extensions

8440-1849 – AMF-focused alternative for utility failover emphasis

8440-2145 – Paralleling-capable model for multi-unit growth paths

8237-1001 – Legacy easYgen unit for economical single-genset retrofits

Before slotting the Woodward 8440-1546H into service, match your alternator’s PT range to the module’s 120-480 Vac inputs to avert mismatch alarms, and scout DIN rail clearance for its 160 mm width—overlaps can crimp heat escape in enclosed vaults. Lock down the supply at 12/24 Vdc with surge clamping above 36 V to dodge latchups, and snapshot ToolKit baselines to the H firmware for ruggedized presets like extended debounce on vibration-prone discretes. Probe ECU baud rates if J1939 linking, as offsets spawn dropout logs early.

Keep-watch protocols favor quarterly LED patrols for run-hour tallies or inhibit flags, mated with lug checks for corrosion in outdoor housings—a vinegar rinse neutralizes buildup sans abrasives. Semiannual log pulls over RS-485 reveal drift in speed refs, priming gain trims during off-peak idles. For battery-buffered clocks, swap CR2032 cells yearly to fend off timestamp gaps, powering off isolated first. These no-frills tactics, forged from site logs, nurture the Woodward 8440-1546H‘s dependability with scant footprint on workflows.

WhatsApp: +86 16626708626

WhatsApp: +86 16626708626 Email:

Email:  Phone: +86 16626708626

Phone: +86 16626708626