Description

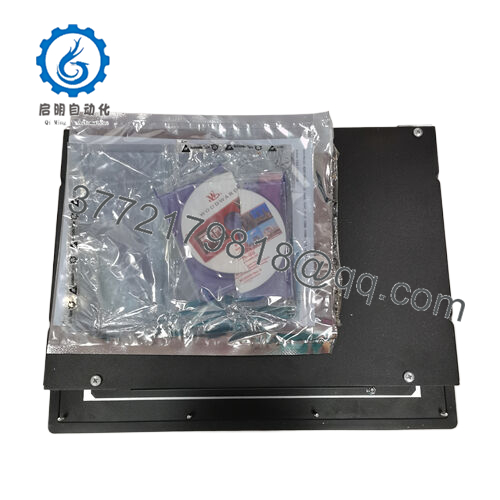

Woodward 8237-1600 is a high-performance digital controller that belongs to Woodward’s highly acclaimed product line. It is designed as the core component for controlling and monitoring various types of turbines, and is an indispensable part of industrial control systems. As a key component in the control architecture, it is connected to numerous sensors and actuators. The speed sensor provides real-time turbine speed data, while temperature and pressure sensors provide additional important information about operating conditions. Then, Woodward 8237-1600 utilizes its advanced microprocessor based algorithms to process this data.

8237-1600

Based on the analyzed data, it will send precise control signals to actuators such as fuel valves for gas turbines or steam inlet valves for steam turbines. This enables it to accurately adjust the speed of the turbine. It can be seamlessly integrated into existing control systems, whether they are simple independent systems in small industrial applications or complex network systems in large power plants. For engineers and system integrators, the Woodward 8237-1600 is a game changing product. Its user-friendly programming interface makes it easy to configure control parameters. This means that engineers can quickly adapt it to different turbine models and operational requirements, reducing the time and effort required for system debugging and maintenance.

8237-1600

Main features and advantages:

One of the most notable features of Woodward 8237-1600 is its excellent speed control accuracy. It can maintain the turbine speed within a very narrow tolerance range, typically within ± 0.1% of the set point. This accuracy is crucial for applications where even small changes in speed can have a significant impact on performance. For example, in power production, a stable turbine speed is crucial for generating electrical energy with consistent frequency, and frequency stability of electrical energy is essential for the stable operation of the power grid.

The Woodward 8237-1600also features advanced diagnostic capabilities. It will continuously monitor its internal components as well as the connected sensors and actuators. If any abnormal situation is detected, such as sensor failure or deviation in expected control response, it will immediately generate detailed diagnostic information. These pieces of information help maintenance personnel quickly identify the root cause of problems, minimize downtime, and lower maintenance costs.

In terms of hardware design, the Woodward 8237-1600is durable and long-lasting. Its sturdy casing can protect it from the common harsh conditions in industrial environments, including high temperatures, humidity, and dust. This ensures reliable operation even in the most challenging environments. It also has extensive power compatibility and can accept inputs such as 24 VDC, 115 VAC, 240 VAC, and 125 VDC. This multifunctionality makes it suitable for different regions and application scenarios without the need for complex power conversion systems.

Long term reliability is the cornerstone of Woodward 8237-1600. During the manufacturing process, it undergoes rigorous testing to meet the highest quality standards. The use of high-quality components and advanced manufacturing technology helps to extend its lifespan and provide users with long-term reliable solutions for turbine control needs.

8237-1600

Technical specifications;

Model 8237-1600

Brand Woodward

Type: Digital Turbine Controller

Power supply 24 VDC, 115 VAC, 240 VAC, 125 VDC

Working temperature -20 ° C to 60 ° C

Installation method: DIN rail installation or panel installation

Contact Us

Phone:+86 16626708626

WhatsApp/WeChat:+86 16626708626

Email: 3772179818@qq.com

8237-1600

Application areas:

In power plants, it is crucial to maintain optimal operating conditions, whether relying on the powerful power of steam turbines, the efficient performance of gas turbines, or the clean energy of water turbines. For example, steam turbines are the main equipment in many power generation facilities, rotating at high speeds to convert thermal energy into electrical energy. However, any deviation from the ideal speed can lead to low efficiency, reduced power generation, and in extreme cases, even catastrophic mechanical failures. The Woodward 8237-1600 is carefully designed to ensure that steam turbines operate within extremely narrow speed tolerances, maximizing power generation while ensuring safety.

In the oil and gas industry, gas turbines are used for various critical applications. They provide power for compressors, allowing oil and natural gas to be transported over long distances through pipelines. Unstable or incorrect speed of gas turbines can disrupt the entire transportation process, resulting in high production costs, delays, and potential safety risks. The Woodward 8237-1600 was born to provide precise speed control, ensuring smooth and reliable operation of gas turbines. In addition, Woodward 8237-1600also plays a key role in manufacturing plants with large industrial machinery such as high-speed compressors and motors. These machines need to operate at a specific speed to maintain product quality and production efficiency. The controller will monitor and adjust the speed in real time to prevent any deceleration or overspeed that may cause product defects or equipment damage.

8237-1600

Related products:

Woodward 8237-1369- Another overspeed protection device in the Woodward product portfolio that can be used in conjunction with 8237-1600 to enhance the safety of turbine operation. 8237-1369 focuses more on rapid overspeed detection and emergency shutdown, while 8237-1600 is responsible for continuous speed control.

8237-1600

Installation and maintenance:

It is crucial to carefully plan the installation location before installing Woodward 8237-1600. The area should be well ventilated to dissipate the heat generated during the operation of the controller. Good ventilation helps maintain the optimal operating temperature of equipment, which is crucial for its long-term performance and reliability. In addition, the installation location should be far away from strong electromagnetic interference sources, such as large motors or high-voltage transformers. Electromagnetic interference may interfere with the communication between controllers, sensors, and actuators, leading to inaccurate control and potential system failures.

Regular visual inspections are essential for maintenance. Check for any physical signs of damage to the casing, such as cracks or dents, which may affect its protective ability. Check all connections, including power cables, communication lines, and sensor/actuator connections, to ensure they are secure and free of corrosion. Regularly calibrating connected sensors is also important. Due to the reliance of 8237-1600 on accurate sensor data for control operations, calibrated sensors ensure that the controller makes precise decisions. Software updates should be applied promptly. Woodward often releases updates to improve the functionality of controllers, fix vulnerabilities, and enhance their compatibility with new devices. However, it is recommended to test in a non production environment before applying any updates to ensure compatibility issues with existing systems.

HIMA Other Product Models:

HIMA PS1000WR011

HIMA F3DIO20/802 982200484

Hima F8621A

HIMA F8627X 984862765

HIMA 80105 984080105

HIMA ELOP II V5.5

HIMA 80105 984080105

HIMA X-SB01 985210207

HIMA F8628X

HIMA F8650X 984865065

HIMA A1-dig 984200004

HIMA X-AI3201 985210213

HIMA TRIX F35 982200416

HIMA F3DIO20/802 982200442

HIMA F8650E

HIMA F3226A

HIMA F8621A 984862160

HIMA F-PWR01

HIMA F3DIO16/801

HIMA Z7130

HIMA F3240

HIMA F30 03 SILworX 20/9

HIMA F3237

HIMA F8651X

HIMA F3DIO20/802 982200404

HiMA F35 030 34 SILworX

HIMA F-COM01

HIMA F-IOP01

HIMA F30 F30 010 20 OS-REV.V6.46/V11.28

HIMA F30 F30 010 20 OS-REV.V6.46/V11.28

WhatsApp: +86 16626708626

WhatsApp: +86 16626708626 Email: 3772179818@qq.com

Email: 3772179818@qq.com Phone: +86 16626708626

Phone: +86 16626708626