Description

The Woodward 8237-1369 model is an advanced overspeed protection device belonging to Woodward’s renowned ProTech GII series. It is specifically designed to protect steam turbines and other rotating equipment from the dangers of overspeed and excessive acceleration. As a key component in industrial safety systems, it integrates into the overall control system architecture by continuously monitoring the rotational speed of rotating machinery.

8237-1369

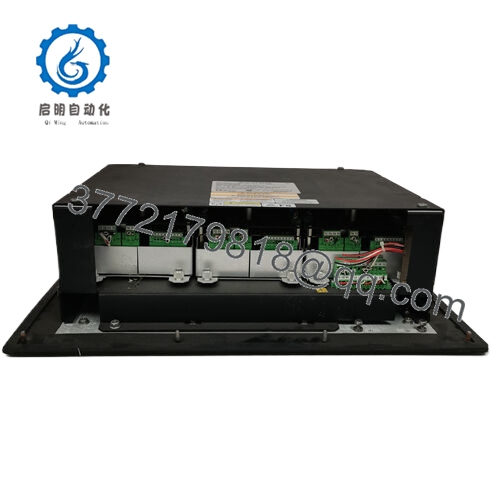

The device is connected to a speed sensor installed on the turbine or equipment shaft. It receives real-time speed data and uses complex algorithms for analysis. If the detected speed exceeds the preset safety limit, the Woodward 8237-1369 device will quickly send a signal, triggering an emergency stop procedure. For engineers and system integrators, the value of the Woodward 8237-1369 device lies in its reliability and ease of integration. It can seamlessly integrate into existing control systems, whether it’s simple standalone setups or complex networked industrial automation systems. Its standardized interface and communication protocol make it a universal choice for various applications.

8237-1369

Main features and advantages:

One of the most impressive features of the Woodward 8237-1369 device is its lightning fast response time. When overspeed occurs, it can detect anomalies within milliseconds and take corrective measures. This rapid response is crucial as it can minimize the damage that may occur during overspeed events. Its advanced diagnostic capability is also a major advantage. The device will continuously monitor its internal components and incoming speed signals to detect any signs of malfunction. If a problem is found, it can provide detailed fault information to help maintenance personnel quickly identify and solve the problem.

The Woodward 8237-1369 device was designed with sufficient consideration for durability. It is designed to withstand harsh industrial environments, including extreme temperatures, high humidity, and electrical interference. Its casing is designed to protect internal components from dust, dirt, and moisture, ensuring reliable operation even under the harshest conditions. In terms of compatibility, it supports multiple industry standard communication protocols, such as Modbus. This allows it to effectively communicate with other control devices in the system, such as programmable logic controllers (PLCs) and human-machine interfaces (HMIs).

Long term reliability is another advantage of the Woodward 8237-1369 device. It undergoes rigorous testing during the manufacturing process to ensure compliance with the highest quality standards. The use of high-quality components and advanced manufacturing technology helps to extend their lifespan. In addition, it also has the ability to resist sulfur pollution, as well as the ability to resist H ₂ S and SO ₂ gases, which are particularly beneficial in industries such as oil and gas where these gases are commonly present.

8237-1369

Technical specifications;

Model 8237-1369

Brand Woodward

Type of overspeed protection device

Power supply 24 VDC

Interface Modbus (RS-485, Ethernet), if there are other interfaces, they should also be listed

Cooling method: natural convection

Contact Us

Phone:+86 16626708626

WhatsApp/WeChat:+86 16626708626

Email: 3772179818@qq.com

8237-1369

Application areas:

Safety and reliability are crucial in the high-risk areas of power generation and industrial machinery operation. The Woodward 8237-1369 ProTech GII overspeed protection device plays a critical protective role in multiple industries. In power plants, whether using steam, gas, or hydropower, steam turbines are the core equipment for power generation. These large machines rotate at high speed to generate electricity. However, if the turbine speed exceeds the safe operating speed due to sudden changes in load, mechanical failures, or control system malfunctions, the consequences will be unimaginable. This is precisely where the Woodward 8237-1369device plays an important role.

In the oil and gas industry, gas turbines are used for various applications, from powering pumps in pipelines to supplying power to remote drilling platforms. Once these steam turbines experience overspeed events, it may lead to equipment damage, production interruption, and even pose safety risks to personnel. The Woodward8237-1369 device is designed to detect any abnormal increase in speed and take immediate action to prevent such disasters from occurring. Similarly, in manufacturing plants that rely on large rotating equipment such as compressors and motors, unexpected overspeed can cause serious damage to mechanical equipment and disrupt production lines. The Woodward 8237-1369 device is like a vigilant guardian, ensuring that all rotating equipment operates within a safe speed range.

8237-1369

Related products:

Woodward 8237-1596- belongs to the same ProTech GII series, designed specifically for slightly different turbine sizes or with varying communication capabilities.

Woodward 8237-1597- Has different pre-set safety restrictions for specific applications.

Woodward ProTech 203- ProTech – Compared to the 8237-1369 model, the overspeed protection function is more basic.

HMI unit compatible with Woodward system – allows operators to monitor the status of the 8237-1369 device and set or adjust safety parameters.

Communication module for expanding network connectivity – can be used to enhance the communication range and capability of 8237-1369 devices in large industrial networks.

Installation and maintenance:

Before installing the Woodward 8237-1369 device, it is necessary to carefully consider the installation location. Ensure that there is sufficient space around the area for proper ventilation of equipment. Good ventilation helps dissipate the heat generated during normal operation of equipment, which is crucial for maintaining its performance and lifespan. In addition, attention should be paid to the electrical environment. The device should be installed away from strong electromagnetic fields, such as those generated by large motors or transformers, as these may interfere with its operation. Proper grounding of the 8237-1369 device is crucial. Strictly follow the manufacturer’s guidelines to ensure correct and safe grounding connections and prevent electrical surges.

For maintenance, it is recommended to conduct regular visual inspections at least once a month. Check for any physical signs of damage to the casing, such as cracks or dents. Check all connections, including power and communication lines, to ensure they are securely connected and free from corrosion. Regular functional testing should be conducted to verify whether the overspeed protection mechanism works as expected. This can be achieved by simulating controlled overspeed conditions in a safe and testing environment. In addition, pay attention to the diagnostic information of the equipment. If any malfunctions are reported, please immediately use the detailed troubleshooting guide provided by Woodward for resolution.

HIMA Other Product Models:

HIMA PS1000WR011

HIMA F3DIO20/802 982200484

Hima F8621A

HIMA F8627X 984862765

HIMA 80105 984080105

HIMA ELOP II V5.5

HIMA 80105 984080105

HIMA X-SB01 985210207

HIMA F8628X

HIMA F8650X 984865065

HIMA A1-dig 984200004

HIMA X-AI3201 985210213

HIMA TRIX F35 982200416

HIMA F3DIO20/802 982200442

HIMA F8650E

HIMA F3226A

HIMA F8621A 984862160

HIMA F-PWR01

HIMA F3DIO16/801

HIMA Z7130

HIMA F3240

HIMA F30 03 SILworX 20/9

HIMA F3237

HIMA F8651X

HIMA F3DIO20/802 982200404

HiMA F35 030 34 SILworX

HIMA F-COM01

HIMA F-IOP01

HIMA F30 F30 010 20 OS-REV.V6.46/V11.28

HIMA F30 F30 010 20 OS-REV.V6.46/V11.28

WhatsApp: +86 16626708626

WhatsApp: +86 16626708626 Email: 3772179818@qq.com

Email: 3772179818@qq.com Phone: +86 16626708626

Phone: +86 16626708626