Description

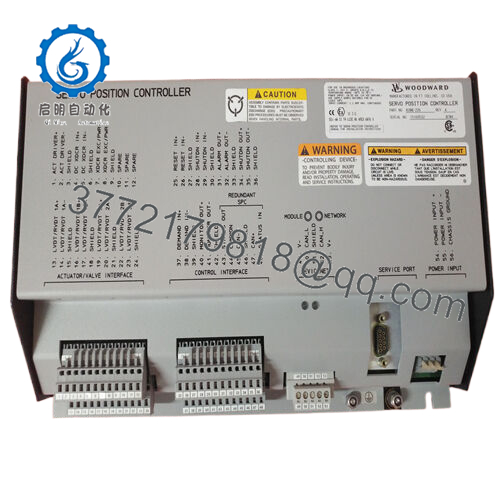

Product Model: Woodward 8200-226

- Brand: Woodward

- Series: 8200 Digital Governor Series

- Product Type: Engine / Turbine Governor Control Module

- Key Features:

- Digital governor for precision speed and load control

- Compatible with industrial engines and turbines

- High reliability in continuous-duty, harsh environments

- Advanced control algorithms for stability and efficiency

Industrial Applications and Context

In modern industrial operations, precise engine and turbine control is critical for power generation, marine propulsion, and heavy machinery. Fluctuations in load, speed, or fuel delivery can reduce efficiency, increase wear, or even lead to unsafe operating conditions.

The Woodward 8200-226 digital governor is designed to solve these challenges. As part of the 8200 series, it provides reliable digital control of engine speed and load, optimizing performance while maintaining safety and compliance in demanding industrial environments.

Whether in power plants, offshore rigs, or large industrial engines, the 8200-226 ensures smooth operation, reduced emissions, and precise synchronization with other power sources.

Role of the Woodward 8200-226

The 8200-226 serves as a governor and engine control module, responsible for:

- Maintaining engine or turbine speed under varying load conditions

- Managing fuel flow to optimize efficiency and minimize emissions

- Coordinating with safety interlocks to prevent overspeed or overloading

- Providing diagnostics and feedback for operators and maintenance systems

By integrating seamlessly with both analog and digital sensors, the 8200-226 delivers fast, accurate, and fail-safe control, ensuring plant or engine operations remain reliable under all conditions.

Technical Features and Benefits

Core Features

- Digital Governor Control: Precise speed regulation using advanced algorithms

- Compatibility: Supports diesel, gas, and dual-fuel engines, as well as turbines

- Integrated Safety Functions: Overspeed protection, shutdown logic, and load sharing

- Diagnostics & Monitoring: Provides real-time feedback for predictive maintenance

- High-Reliability Design: Industrial-grade components withstand vibration, heat, and EMI

- Flexible Communication: Interfaces with plant automation systems and HMIs

- Ease of Integration: Compatible with existing Woodward 8200 series equipment

Benefits

- Improved Efficiency: Optimized fuel delivery reduces consumption

- Operational Safety: Overspeed and fault protection mechanisms prevent damage

- Reduced Downtime: Advanced diagnostics help anticipate maintenance needs

- Regulatory Compliance: Supports emissions and safety standards for industrial engines

- Versatility: Can be applied to multiple engine and turbine types

- 8200-226

Technical Specifications

| Specification | Details |

|---|---|

| Model | Woodward 8200-226 |

| Type | Digital Governor / Engine Control Module |

| Series | 8200 Digital Governor Series |

| Function | Engine and turbine speed/load regulation |

| Control Modes | Speed control, load control, droop compensation |

| Inputs | Analog speed sensors, digital signals |

| Outputs | Fuel actuator control, alarm signals |

| Protection | Overspeed, overtemperature, load limiting |

| Communication | CAN, Modbus, proprietary Woodward interfaces |

| Mounting | Rack-mounted or engine-integrated |

| Applications | Power generation, turbines, industrial engines, marine propulsion |

Applications Across Industries

- Power Generation: Maintains stable frequency and load sharing for synchronous generators

- Oil & Gas: Controls engine-driven pumps and compressors under varying loads

- Marine & Offshore: Precision speed control for propulsion engines and auxiliary generators

- Industrial Manufacturing: Engine-driven machinery with demanding load cycles

- Renewable Hybrid Systems: Integration with turbines or engine backup units for grid stability

The 8200-226 is engineered to deliver consistent performance even under extreme environmental conditions, making it ideal for heavy-duty, continuous-duty applications.

Installation and Maintenance Insights

Installation Guidelines:

- Mount the module according to manufacturer specifications for heat dissipation and vibration resistance

- Connect analog and digital sensors accurately to ensure precise feedback

- Ensure proper grounding and shielding to prevent electrical noise

- Verify system integration with engine controllers and automation networks

Maintenance Recommendations:

- Perform periodic calibration of speed sensors and actuators

- Review diagnostic data regularly to detect early signs of wear or faults

- Keep firmware updated per Woodward service guidelines

- Use spare modules and components to minimize downtime during maintenance

Related Woodward Products

- Woodward 8200-224: Standard digital governor for medium-duty engines

- Woodward 8200-228: High-speed turbine control variant

- Woodward 2301: Analog governor module for older installations

- Woodward Flex 5000: Advanced fuel and engine control system

- Woodward 9905: Remote interface for diagnostics and control

WhatsApp: +86 16626708626

WhatsApp: +86 16626708626 Email:

Email:  Phone: +86 16626708626

Phone: +86 16626708626