Description

In the demanding arena of industrial automation, where turbine speed control must deliver unwavering precision to prevent overspeed catastrophes or inefficient throttling, legacy governors often fall short—struggling with outdated analog responses that can’t adapt to variable loads, leading to vibration spikes, fuel waste, or grid instability. Envision a combined-cycle power plant where steam turbine fluctuations disrupt baseload generation, or a marine propulsion system where erratic RPMs compromise maneuverability amid rough seas; these are the high-stakes moments in process control where I/O signal latency or environmental vulnerabilities can cascade into costly shutdowns. High reliability isn’t optional here—it’s the baseline for compliance with standards like IEC 61508, yet many setups rely on rigid hardware that demands constant recalibration, inflating maintenance cycles and operational risks.

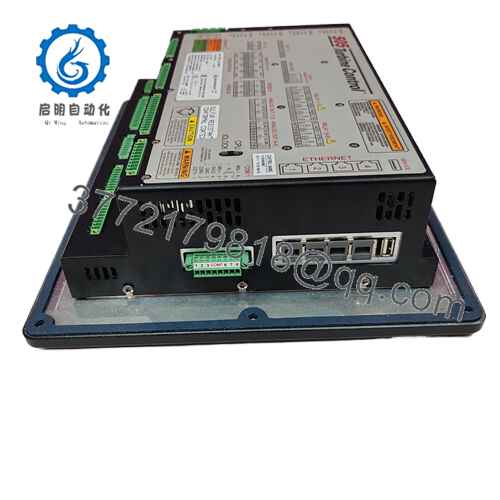

This is the exact impasse the Woodward 8200-1302 navigates as a digital governor system tailored for steam turbines, transforming those pain points into streamlined, adaptive control. In typical deployments like district heating networks or offshore platforms, it emerges as essential during retrofits, where surging energy demands require modular integration without overhauling the entire actuator chain. Without it, operators juggle manual overrides or third-party patches that erode system stability; the Woodward 8200-1302 counters this with its integrated HMI for on-the-fly adjustments, ensuring seamless I/O signal processing for speed reference and load sharing. Its ATEX-rated enclosure withstands corrosive atmospheres, while automatic sequencing for hot/cold starts minimizes thermal stress, a game-changer in environments prone to rapid cycling.

From an engineer’s lens, the Woodward 8200-1302 merits consideration for its ROI in industrial automation: it curtails downtime by preempting faults through embedded alarms and trip inputs, aligning with SIL 2/3 needs while slashing tuning hours via multilingual screens. In power or oil & gas sectors, where regulatory audits loom large, this governor’s EMC-hardened design expedites certification, freeing teams for optimization over remediation. Ultimately, it’s a consultative ally that fortifies process control, delivering the signal reliability and high reliability that turns turbine vulnerabilities into resilient performance pillars.

Tucked into the heart of your turbine control architecture, the Woodward 8200-1302 operates as the intelligent nexus between field sensors and actuators, leveraging its 32-bit processor to execute PID loops for precise speed regulation—think of it as the vigilant conductor orchestrating throttle valves and governors in real-time. It mounts via standard DIN-rail in control cabinets, interfacing with the 505 series backplane for shared data exchange, where analog inputs from speed probes or temperature transducers feed directly into its configurable algorithms. Positioned at the core of the automation stack, it bridges SCADA overlays and local HMIs, supporting protocols like Modbus RTU over RS-485 for effortless integration with legacy DCS or modern Ethernet networks.

In action, the Woodward 8200-1302 shines through its layered diagnostics: it monitors actuator feedback via 4-20 mA loops, flagging discrepancies like hydraulic drift before they impact stability, and enables redundancy by paralleling with a secondary unit for bumpless transfer during faults. For a steam turbine driving a compressor, it handles critical speed avoidance by ramping outputs in segmented profiles, ensuring safe passage through resonance bands without operator intervention. This modularity extends to I/O architecture—up to 10 alarm and trip inputs route through isolated channels, buffering against noise in electromagnetic-heavy zones. Paired with Woodward’s servo amps or remote racks, it scales from single-unit gensets to multi-turbine arrays, fostering a fault-tolerant ecosystem where communication latency stays under 10ms. The front-panel HMI, with its graphical LCD and keypad, empowers local overrides, from emergency trips to parameter tweaks, all while logging events for post-trip analysis. This holistic fit keeps your process control agile, whether daisy-chaining to exciters for synchronous generation or buffering load pulses in peaking plants—prioritizing uptime over endless reconfiguration.

| Specification | Details |

|---|---|

| Model Number | 8200-1302 |

| Brand | Woodward |

| Type | Digital Governor System |

| Input Voltage | 88-132 VAC / 90-150 VDC |

| Operating Temp Range | -25°C to +70°C |

| Mounting Style | DIN-rail / Panel |

| Dimensions | 263 x 58 x 28 mm |

| Weight | 4.3 kg |

| Interface/Bus | RS-485, Modbus RTU |

| Compliance | ATEX, IEC 61508 SIL 2/3, EMC EN 61000-6-2, CE, IACS UR E10 |

| Supported Protocols | Modbus RTU, Ethernet/IP (optional) |

| Typical Power Draw | 15-20 W |

Deploying the Woodward 8200-1302 unlocks a cascade of reliability gains, where its adaptive sequencing algorithms avert startup surges that once plagued cold boots, ensuring turbines spool up smoothly to setpoint without overshoot—translating to smoother grid ties and fewer wear cycles on blades or couplings. In the thick of variable loads, this engineered foresight maintains speed droop within 0.5%, stabilizing frequency excursions that could otherwise ripple through downstream processes, all while its isolated I/O guards against transient spikes from nearby switchgear.

8200-1302

8200-1302

Maintenance takes a lighter touch too, as the system’s self-diagnostics surface anomalies via event recorders, pinpointing a drifting sensor in minutes rather than days of oscilloscope hunts, which eases engineering overhead and extends intervals between full calibrations. Built for the grind of continuous duty, it assures long-term performance with conformal-coated boards that resist humidity in coastal installs, dialing down failure rates and sharpening your O&M forecasts. For expanding fleets, the Woodward 8200-1302‘s plug-in modularity cuts integration snags, letting you layer on remote monitoring without recoding core logic.

Beyond the turbine face, its multilingual HMI fosters operator confidence, reducing training curves and human-error trips during shift changes—vital in 24/7 ops. Teams leveraging it report tighter load sharing in co-gen setups, boosting efficiency by 2-3% through precise valve modulation. It’s this blend of proactive safeguards and intuitive handling that renders the Woodward 8200-1302 a cornerstone for resilient automation, one that not only meets today’s demands but anticipates tomorrow’s throughput pressures.

In utility-scale power generation, the Woodward 8200-1302 governs condensing steam turbines for baseload output, where continuous uptime under grid fluctuations is paramount—its critical speed evasion and temp-compensated inputs sustain high reliability, pulsing actuators in sub-second loops to dodge resonance amid 60Hz syncing in process control environments.

Aboard LNG carriers, it commands propulsion turbines through corrosive brines and fuel variability, with ATEX compliance enabling Zone 2 installs; here, in harsh conditions demanding SIL 3 integrity, the Woodward 8200-1302 buffers alarm cascades from vibration monitors, ensuring fail-safe throttling for safe docking maneuvers.

Within petrochemical crackers, the module orchestrates expander turbines for gas compression, handling fast data cycles from orifice plates to optimize yields—its modular rack fit allows hot swaps during turnarounds, minimizing exposure in volatile zones. These applications underscore the Woodward 8200-1302‘s versatility for industrial automation experts engineering against overloads and excursions.

8200-1301 – AC/DC variant for hazardous locations with enhanced enclosure ratings

8200-1300 – Base model for standard industrial setups, lower voltage input for cost-sensitive retrofits

8200-1310 – HVAC/DC edition with integrated cooling for high-ambient turbine houses

505-7150 – Core digital controller module, pairs with 8200-1302 for full 505E system builds

8238-100 – Servo actuator companion for hydraulic throttling in steam applications

8446-1037 – Analog I/O expansion board to augment 8200-1302’s sensor channels

8200-1312 – LVDC hazardous-area model for offshore oil & gas turbine drives

5466-317 – Remote HMI display for distributed monitoring alongside the 8200-1302 panel

Prior to energizing the Woodward 8200-1302, audit your turbine’s shaft speed range—mismatches with the governor’s 0-10k RPM setpoint can skew PID gains, so benchmark against the 505 manual’s tuning wizard. Confirm cabinet clearance for the panel’s bezel; in dusty enclosures, factor 50mm vents to sustain airflow over the LCD, and test your AC/DC rails for <5% ripple to avert boot glitches. Firmware sync is key—download the latest via Woodward’s Toolbox software, verifying checksums before upload to dodge logic faults.

In routine care, quarterly LED sweeps for steady green on power and comms catch early drift, paired with a Modbus poll for input variances exceeding 1%. Biannually, cycle through self-tests in the HMI’s diagnostic menu—simulate a trip input to clock response under 50ms—and inspect terminal blocks for torque creep, especially post-vibration events. For marine units, annual IP-rated connector wipes with deionized solution prevent salt bridging, while archiving event logs quarterly aids trend-spotting for predictive swaps. These habits mesh into your PM flow, preserving the Woodward 8200-1302‘s acuity without commandeering shop time.

WhatsApp: +86 16626708626

WhatsApp: +86 16626708626 Email:

Email:  Phone: +86 16626708626

Phone: +86 16626708626