Description

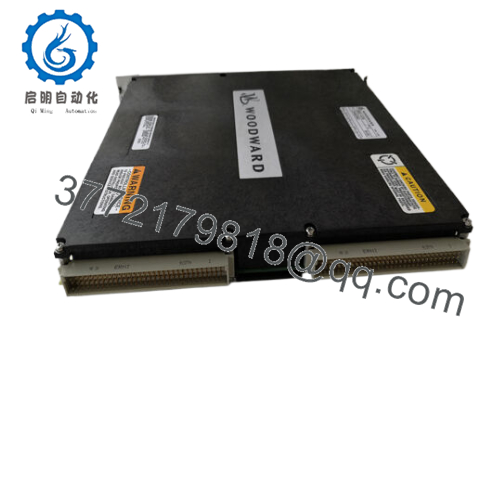

The Woodward 5501-470 is a central processing unit (CPU) module primarily used in industrial automation systems focused on motor-driven compressor control and turbine control applications. It is an essential component in legacy NetCon and MicroNet control architectures, utilized within industries like power generation, oil and gas, and process manufacturing. Operators in these sectors rely on the 5501-470 to deliver fast, reliable digital processing needed to maintain precise control over rotating equipment, ensuring safe and efficient operation. Industrial environments often demand high availability from their control modules to prevent costly downtime and maintain process stability, and this Woodward CPU module is engineered to meet those stringent requirements. Its role extends beyond processing—forming the heart of control platforms that interface with sensors, actuators, and communication modules to orchestrate complex machine functions.

The 5501-470 CPU module is a digital controller board that fits into a VME bus architecture used in Woodward’s NetCon and MicroNet series of control systems. It acts as the main processing engine for executing control algorithms and managing input/output communications. This module omits local logic memory, relying on external memory to support its functions, which was typical of control systems designed in the 1990s to early 2000s. It interfaces with digital and analog I/O modules, actuator control units, and communication devices to form a complete control system. While it is now considered legacy hardware, the 5501-470 remains critical for maintaining and replacing parts in existing industrial installations. Engineers and system integrators value it for its compatibility with the original NetCon system infrastructure and for sustaining operational continuity in plants where system upgrades are planned but not yet complete.

- 5501-470

The key technical attributes of the Woodward 5501-470 highlight its high-performance CPU capabilities paired with robust industrial design. It offers 470 KB of memory capacity and supports configurations such as single-board, dual-board, or triple-board setups for flexible deployment based on application needs. Its VME bus interface supports real-time data exchange across the control rack, enabling synchronized control and monitoring. The module is designed to operate in harsh environments with an operating temperature range of -40°C to +85°C, making it reliable for use in demanding conditions. Its EMI filter protects against electrical noise prevalent in industrial power plants and compressor stations.

Designed to interface with motor-driven compressor control platforms, the 5501-470 ensures low latency and deterministic processing critical for real-time control loops. Its digital processing power supports complex logic execution necessary for efficient compressor regulation and turbine protection. Despite its legacy status, Woodward offers repair services and last-time buys to support equipment still in the field. This module seamlessly integrates with a range of Woodward’s industrial I/O and communication modules, enabling continued relevance in legacy systems still handling extensive daily operation cycles.

| Parameter | Value |

|---|---|

| Model | 5501-470 |

| Brand | Woodward |

| Product Type | Central Processing Unit Module |

| Memory Capacity | 470 KB |

| Interface | VME Bus |

| Configuration Options | Single-board, dual-board, triple-board |

| Operating Temperature | -40°C to +85°C |

| Mounting | Rack-mounted VME chassis |

| Control Type | Motor-driven compressor control |

| EMI Protection | EMI Filter included |

| Legacy Compatibility | NetCon / MicroNet control systems |

The Woodward 5501-470 pairs with modules such as the 5501-469 (a CPU module variant with different memory configurations), 5466-1245 CPU5200 module (a modern replacement CPU), 5466-1047 TMR CPU module for triple modular redundancy systems, and various I/O modules like the 5464-823 and 5466-360 master CPUs. These related units help maintain or upgrade existing control system infrastructures while providing compatible functions in a range of industrial setups.

Installing the Woodward 5501-470 module requires a compatible VME chassis with adequate power and cooling provisions. Proper grounding and shielding are necessary to mitigate electromagnetic interference common in industrial applications. Engineers should ensure the control rack housing the CPU has sufficient physical space and environmental controls to maintain operating temperatures within the specified range. Wiring and connector integrity should be checked for reliable system communication.

Maintenance of the 5501-470 module revolves around periodic inspections of the physical module and surrounding rack environment, including routine cleaning to remove dust and contaminants. Diagnostic routines should be performed regularly to check CPU health, memory integrity, and communication status. Firmware or software updates, if applicable, must be carefully managed to avoid operational disruption. Supporting legacy hardware often requires keeping spare modules and maintaining detailed operational logs for troubleshooting.

WhatsApp: +86 16626708626

WhatsApp: +86 16626708626 Email:

Email:  Phone: +86 16626708626

Phone: +86 16626708626