Description

The Woodward 5501-365 is an analog input/output module designed for turbine and compressor control systems in demanding industrial automation environments. It plays a pivotal role in managing precise analog signal exchanges between sensors, actuators, and digital control units. This module is widely implemented in industries such as power generation, oil and gas, and process manufacturing, where accurate governor control, speed sensing, and analog parameter monitoring are critical to operational safety and efficiency. The 5501-365 supports the integration of key analog signals into the control system, enabling real-time adjustments and feedback loops that enhance machine performance while reducing wear and unplanned downtime.

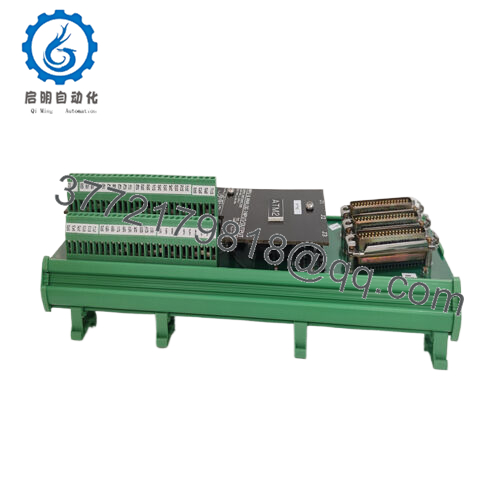

The 5501-365 acts as an interface module within Woodward’s MicroNet and NetCon control platforms. It provides multiple analog input channels capable of handling sensor signals with a maximum input of 25 mA, and analog output channels delivering signals to actuators or other control elements. This module supports precise and flexible control strategies thanks to its microprocessor-based design. It fits easily into a control rack with other input/output and processing modules, helping to centralize analog signal management. Its robust design and compatibility with legacy and modern Woodward systems make it a trusted choice for engineers maintaining or upgrading critical embedded control machinery.

The Woodward 5501-365 distinguishes itself with a rugged build suitable for harsh industrial settings. It is rated for operating temperatures from -40°C to +85°C and can withstand significant vibration and shock loads, meeting the high durability demands of rotating machinery environments. The module offers reliable analog signal conditioning and isolation, essential for noise immunity and accurate data interpretation in electrically noisy plants. It features screw terminal connectors or slide lock posts, facilitating secure wiring and straightforward installation or replacement in industrial panels. The 5501-365 supports analog voltage outputs (0-10 V DC) and current inputs, optimizing interaction with a wide range of sensors and actuator devices.

- 5501-365

With its flexible analog input/output capacity, the 5501-365 allows for efficient integration of feedback sensors such as MPUs, thermistors, and actuators for governor and speed control. Its role in closed-loop control systems is critical for maintaining consistent turbine speed and load conditions, thereby improving system responsiveness and reducing mechanical stress. Engineers benefit from its compatibility with Woodward’s networked control architectures, allowing seamless communication and system diagnostics that support preventative maintenance initiatives.

| Parameter | Value |

|---|---|

| Model | 5501-365 |

| Brand | Woodward |

| Product Type | Analog Input/Output Module |

| Analog Input Capacity | Up to 25 mA maximum input current |

| Analog Output | 0-10 V DC voltage output |

| Operating Temperature | -40°C to +85°C |

| Mounting | Rack-mounted within MicroNet or NetCon chassis |

| Shock and Vibration | 10 G shock at 45 Hz, 4 G vibration 40-2000 Hz |

| Terminations | Screw terminals or slide lock posts |

| Power Supply | Typically powered by system rack supply |

Related products to the Woodward 5501-365 include the 5501-364 (digital input/output module complementing analog capabilities), 5466-1105 (high-density combo I/O module with advanced speed and analog inputs), 5501-372 (TMR analog I/O module for redundancy), 5466-1246 (real-time network transceiver for system communication), and the 5501-376 (high-density analog input/output for simplex systems). These units collectively support comprehensive analog and digital signal management in control platforms.

Installation of the 5501-365 involves securing the module within a compatible Woodward control rack, often MicroNet or NetCon series configurations. Ensuring proper grounding and maintaining wiring integrity enhances noise immunity for accurate analog signal transmission. Space planning should consider heat dissipation and vibration isolation, as the module operates in environments with significant mechanical stress.

Maintenance includes routine inspections for wiring, connectors, and physical damage or contamination. Regular functional checks using diagnostic tools help verify analog signal fidelity and module output accuracy. Preventative program updates and thorough system integration tests ensure ongoing reliability and compliance with control objectives.

WhatsApp: +86 16626708626

WhatsApp: +86 16626708626 Email:

Email:  Phone: +86 16626708626

Phone: +86 16626708626