Description

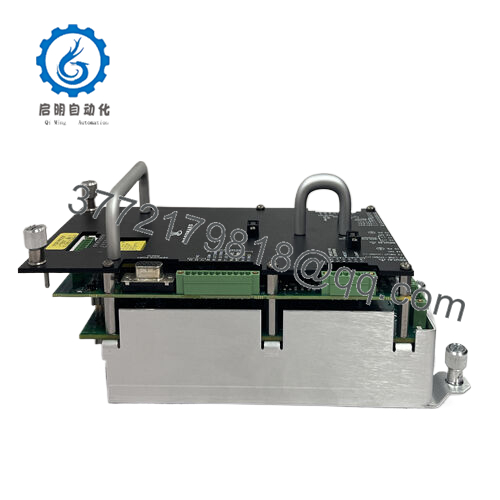

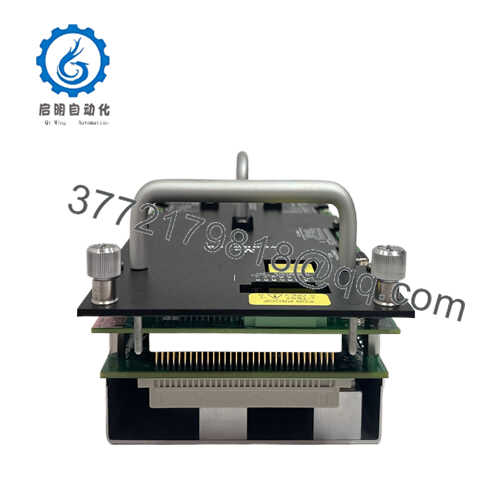

Woodward 5437-1119 is a state-of-the-art electronic control module that serves as a central hub for managing engine related functions. It is connected to a series of sensors to monitor key parameters of the engine, such as engine speed, exhaust gas temperature, and intake pressure.

5437-1119

By analyzing the data transmitted by these sensors in real-time, the module can accurately adjust the fuel injection system and fine tune the amount of fuel delivered to the engine cylinders. This not only maximizes fuel efficiency, but also ensures smooth operation of the engine under different loads. In industrial automation systems, it can be easily integrated with other key components such as engine control units, power management systems, and monitoring and data acquisition (SCADA) platforms. This module supports industry standard communication protocols such as CAN and RS-485, enabling easy communication with other devices in the system, achieving seamless data exchange and collaborative operation. In addition, Woodward 5437-1119 is equipped with advanced diagnostic features that enable engineers to quickly identify and resolve any potential issues, reduce downtime, and improve overall system reliability.

5437-1119

Technical specifications:

Model 5437-1119

Brand Woodward

Type Electronic Control Module

Input voltage 10-30 VDC

Working temperature range -40 ° C to+80 ° C

Installation method: DIN rail installation

Size 140mm x 90mm x 45mm

Weight 1.1 kg

Interface/Bus CAN, RS-485

Certification CE, RoHS

Supports protocols J1939 and Modbus RTU

Typical power consumption 7.5 W

Contact Us

Phone:+86 16626708626

WhatsApp/WeChat:+86 16626708626

Email: 3772179818@qq.com

5437-1119

Main features and advantages:

This module has been carefully designed to withstand the harsh industrial environment and ensure long-term reliable operation. Its precise fuel control capability can significantly save fuel consumption over time, directly reducing operating costs. By keeping the engine in optimal operating condition, it extends the service life of engine components, reduces the frequency of maintenance and replacement, and further lowers costs.

The rapid response of this module to changes in load demand ensures stable power output, which is crucial for maintaining the integrity of industrial processes and preventing interruptions. In addition, its user-friendly software based configuration system reduces engineering costs, allowing engineers to easily adapt module settings to different engine types and operating scenarios without the need for complex hardware modifications.

5437-1119

Application areas:

In the power generation industry, it is used for diesel and gas generators to optimize their performance and ensure stable and reliable power supply in both grid connected and off grid applications.

In the field of ships, it plays a crucial role in controlling ship engines, enabling efficient navigation and operation even in challenging sea conditions. It is also an important component of the oil and gas industry, helping to manage the engines that power pumps, compressors, and other critical equipment, ensuring continuous safe operation in harsh remote locations with extreme temperatures and high vibration levels.

5437-1119

Related products:

Woodward 5437-1120: Enhanced processing power, increased input/output channels, suitable for more complex control applications.

Woodward 5437-1118: More basic in functionality, suitable for engine control tasks with lower requirements.

Woodward 5437-1119H: Designed specifically for use in hazardous environments, with higher safety levels and explosion-proof structures.

Woodward 5437-1119 Lite: retains core control functions, making it ideal for entry-level engine control needs.

Woodward 5437-1119- Pro: Provides advanced predictive diagnostic capabilities for proactive maintenance and more comprehensive system monitoring.

Installation and maintenance:

Before installing Woodward 5437-1119, it is essential to thoroughly check the compatibility of its input voltage with the existing power system to ensure that the voltage remains within the range of 10-30 VDC. Verify communication bus compatibility with other devices in the system, including sensors, actuators, and control units, to ensure seamless data transmission. In addition, confirm that the software used for configuration and monitoring is the latest version and has been properly authorized.

For daily maintenance, the status indicator lights of the module should be checked regularly to quickly detect any abnormal situations. Regularly check the connection of the module to ensure that it is secure and free from corrosion or damage. Conducting routine performance testing, such as simulating sudden load changes and evaluating module response time, helps ensure that it continues to operate at optimal efficiency and reliability.

WOODWARD related products:

Woodward 5466-409

Woodward 8200-226

WOODWARD 8200-1302

WOODWARD 8440-2082

WOODWARD 8440-2052 F EASYGEN-3200

WOODWARD 8440-2052 H EASYGEN-3200

WOODWARD 9906-619

WOODWARD 8521-0071

WOODWARD EGCP-3 8406-113

WOODWARD 8200-1302

WOODWARD TRICON 3805E

WOODWARD 8273-1011

WOODWARD 8440-1706

WOODWARD 8540-645

WOODWARD 9907-167

WOODWARD 8237-1247

WOODWARD 8237-1247

woodward 8404-030

WOODWARD 8237-1246

WOODWARD 5437-1119

Woodward 1766-541

Woodward 8440-2052 H EASYGEN-3200

WOODWARD 8237-1247

WOODWARD 8440-1706

Woodward 8273-140

Woodward DPG-2223-002

Woodward 8440-2028

WOODWARD EASYGEN-3200 8440-1925D

Woodward 9907-135

WOODWARD 9907-014

WOODWARD 8440-2165

WOODWARD 8405-094

WOODWARD SPM-D2-10 8440-2066A

Woodward 2301A 9907-018

WOODWARD 2301D 8273-126

Woodward MRR1-D

WOODWARD 3200XT

WhatsApp: +86 16626708626

WhatsApp: +86 16626708626 Email: 3772179818@qq.com

Email: 3772179818@qq.com Phone: +86 16626708626

Phone: +86 16626708626