Description

In the high-pressure world of industrial automation, where turbine overspeed events can escalate from minor anomalies to devastating failures in seconds, the fragility of outdated protection schemes becomes glaringly apparent. Engineers in power generation or oil & gas facilities often contend with legacy relays that lag in response times, susceptible to electromagnetic noise or thermal drift, which compromise I/O signal accuracy and expose systems to catastrophic risks like blade fragmentation or fuel fires. These vulnerabilities peak during load transients in gas-fired plants or hydro installations, where rapid acceleration demands instantaneous shutdowns to uphold SIL 3 integrity under IEC 61508—yet many setups force trade-offs between speed and reliability, inflating retrofit costs or inviting regulatory scrutiny. Without a dedicated sentinel, process control loops falter, turning routine startups into potential blackouts.

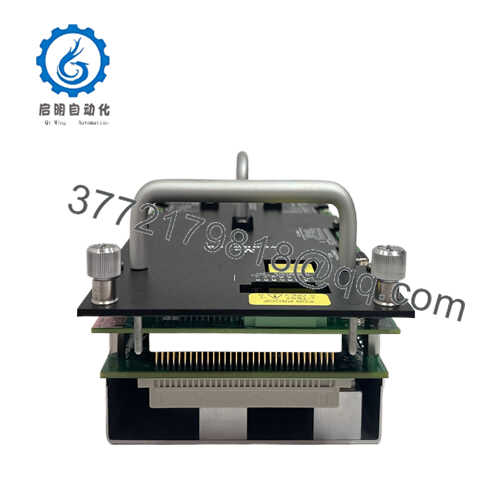

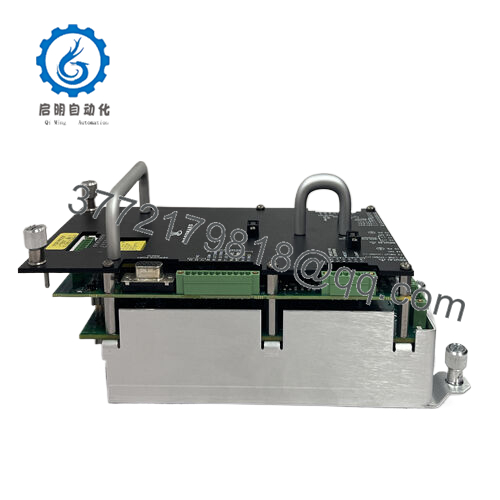

This is the critical void the Woodward 5437-1119 fills as a ProTech-GII overspeed protection module, engineered to detect and neutralize acceleration threats with unyielding precision. In environments like peaking power stations or compressor drives, it proves vital during upgrades, where surging throughput strains existing ESD architectures; absent such a module, operators lean on cumbersome voting systems or manual interventions that erode high reliability. The Woodward 5437-1119 intervenes with redundant signal paths that process speed inputs from MPU or proximity probes in under 20ms, triggering fail-safe trips via isolated relays while logging events for root-cause forensics. Its robust enclosure deflects industrial grit, ensuring I/O signal fidelity amid vibration or humidity spikes.

For teams evaluating safeguards, the Woodward 5437-1119 offers clear decision anchors: it trims nuisance trips through tunable thresholds, aligning with Modbus-integrated DCS for holistic oversight, and its scalable I/O footprint eases expansions without rack overhauls. In turbine-centric operations, where every cycle counts toward availability, this module reframes risks as managed certainties, bolstering process control with the modular integration that sustains uptime and compliance in unforgiving terrains.

At the nexus of your turbine’s safety stack, the Woodward 5437-1119 acts as the decisive arbiter between normal operation and emergency de-escalation, embedding into ProTech-GII chassis where it cross-checks dual-channel speed signals against programmable limits to initiate shutdowns. It slots into DIN-rail assemblies alongside actuator drivers or SCADA gateways, leveraging the system’s 24VDC bus for power while interfacing via Ethernet or Modbus for configuration uploads from Gap software. In the broader I/O architecture, it resides downstream from field sensors—processing 4-20mA analogs from vibration monitors or temperature RTDs—and upstream of trip solenoids, where its voted outputs (2oo3 configurable) ensure no single fault propagates, fostering redundancy in SIL-rated loops.

Deployment leans consultative: the module’s self-diagnostics ping the host controller with heartbeat signals, surfacing discrepancies like probe gaps via front-panel LEDs, so you can preempt issues before they hit the turbine floor. It embraces protocols beyond Modbus, including PROFIBUS for legacy ties, allowing the Woodward 5437-1119 to federate with microNet TMR platforms or remote HMIs without custom middleware. Picture it in a gas turbine’s acceleration profile: raw RPM data buffers through its FPGA-accelerated core, bypassing resonance zones with adaptive delays, then fans out to four relay drivers for fuel cutoff. This positioning amplifies modularity—stack multiples in bulkhead mounts for hydro arrays, or pair with expansion cards for added analog vigilance—while galvanic isolation shields against ground faults in shared cabinets. The upshot? A safety layer that syncs intuitively with your control platform, diagnostics that forecast rather than react, and scalability that accommodates growth without sidelining the turbine.

- 5437-1119

- 5437-1119

| Specification | Details |

|---|---|

| Model Number | 5437-1119 |

| Brand | Woodward |

| Type | Overspeed Protection Module |

| Input Voltage | 24 VDC |

| Operating Temp Range | -20°C to +70°C |

| Mounting Style | DIN-rail / Panel |

| Dimensions | 200 x 120 x 60 mm |

| Weight | 1.5 kg |

| Interface/Bus | Ethernet, Modbus |

| Compliance | IEC 61508 SIL 3, CE, ATEX Zone 2 |

| Supported Protocols | Modbus RTU, Ethernet/IP, PROFIBUS |

| Typical Power Draw | 5-8 W |

Bringing the Woodward 5437-1119 online fortifies reliability at its core, where redundant processing averts false positives from noisy environments—your turbine sustains steady-state runs without the jitter that once masked genuine threats, delivering consistent acceleration curves that honor load demands while dodging overshoots. This engineered vigilance extends to vibration-heavy ops, where isolated inputs preserve signal integrity, letting protective logic execute trips with sub-50ms latency and zero ambiguity.

Efficiency in upkeep follows suit, as the module’s event historian and diagnostic relays surface wear patterns—like degrading probe coils—via networked alerts, shrinking mean time to insight and easing engineering overhead for distributed teams. Tailored for endurance in corrosive atmospheres, it guarantees long-term performance with conformal shielding that weathers humidity cycles, stabilizing failure rates and refining your risk matrices. In maturing fleets, its hot-configurable thresholds streamline audits, bypassing lengthy revalidations for parameter tweaks.

Layer in the broader ecosystem perks: seamless Modbus bridging to enterprise historians cuts data silos, empowering predictive models that forestall events before they spike. Operators navigate fewer gray-area decisions, thanks to clear LED fault encoding, which tightens shift handovers and curbs human-factor downtimes. Choosing the Woodward 5437-1119 invests in a safeguard that evolves with threats, blending acute responsiveness with enduring poise to anchor your industrial automation against the unforeseen.

In gas-fired combined-cycle plants, the Woodward 5437-1119 patrols overspeed in peaking units, where fuel surges and grid ties test limits—its rapid analog sampling upholds critical system uptime, de-energizing valves in process control environments amid 100MW ramps to avert cascading blackouts.

Hydroelectric dams deploy it for Kaplan turbine guards, enduring damp chill and flow variability; in these harsh conditions, the Woodward 5437-1119‘s SIL 3-rated voting sustains high reliability, buffering probe signals against water hammer for glitch-free synchronization.

On offshore platforms, it shields gas expanders from torque spikes, with Zone 2 hardening enabling compact installs—fast data cycles from torque meters trigger ESD in volatile zones, making the Woodward 5437-1119 a linchpin for industrial automation in remote, unrelenting frontiers.

5437-1120 – Enhanced variant with additional vibration inputs for compressor-heavy applications

5437-1001 – Base ProTech-GII CPU module, foundational pair for 5437-1119 relay logic

8237-1246 – Compatible bulkhead mount for panel-integrated 5437-1119 deployments

8237-1369 – Relay output enclosure that houses the 5437-1119 for voted shutdowns

5466-316 – Digital I/O expansion card to augment 5437-1119’s trip channels

5501-1430 – Actuator driver companion for post-trip sequencing with 5437-1119

5437-1118 – Analog input-focused alternative for temp-dominant protection stacks

9907-162 – Speed sensing probe kit optimized for 5437-1119 MPU interfaces

When gearing up the Woodward 5437-1119 for your ProTech-GII frame, cross-check chassis revision—units post-Rev D align for seamless backplane latching, per Woodward’s integration guide, to forestall contact bounce. Probe your 24VDC source for stability under 50mV ripple; coupling with a 5464-947 conditioner mitigates startup inrush—and eyeball terminal blocks for plating integrity, as minor pitting can erode isolation over cycles. Firmware harmony matters too: snag the current Gap package from Woodward’s site, hashing it pre-flash to nix corruption risks.

Ongoing vigilance keeps it sharp: trimonthly scans of status LEDs for solid green on channels, cross-referenced against Modbus queries for variance thresholds beyond 2%. Semiannually, trigger a full proof-test via the HMI—emulate an overspeed pulse to validate trip propagation under 30ms—while torquing field terminals to 1.2 Nm, particularly after seismic events. In saline exposures, biannual enclosure seals get a silicone refresh to block creep, and archive diagnostic dumps quarterly for anomaly trending. These measures fold into standard turbine PMs, sustaining the Woodward 5437-1119‘s vigilance without commandeering resources.

WhatsApp: +86 16626708626

WhatsApp: +86 16626708626 Email:

Email:  Phone: +86 16626708626

Phone: +86 16626708626