Description

Real-World Use & Application Scenarios

The Woodward 2301E digital load sharing and speed control module is widely used in power generation, marine propulsion, and industrial engine applications where multiple generators or prime movers operate in parallel. It is designed to provide precise load sharing and speed regulation, ensuring balanced distribution of load among units, smooth transitions during loading and unloading, and stable engine speed control.

Industries relying on diesel or gaseous engines for power generation need the 2301E to monitor and control generators efficiently, prevent overload conditions, and maintain grid stability. It addresses key challenges such as dynamic load fluctuations, speed variation management, and adapting to different engine types or gearing configurations, making it ideal for new installations or upgrading existing 2301A and 2301D control systems.

Product Introduction & Positioning

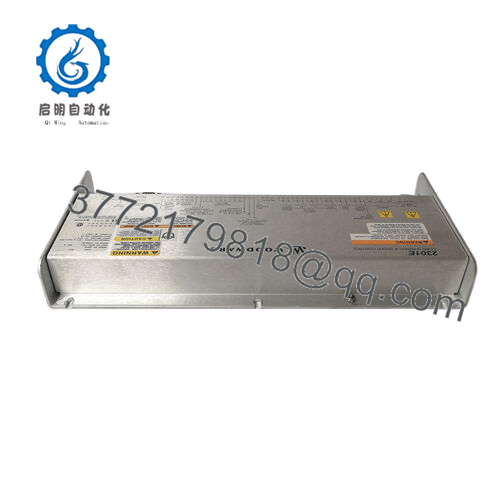

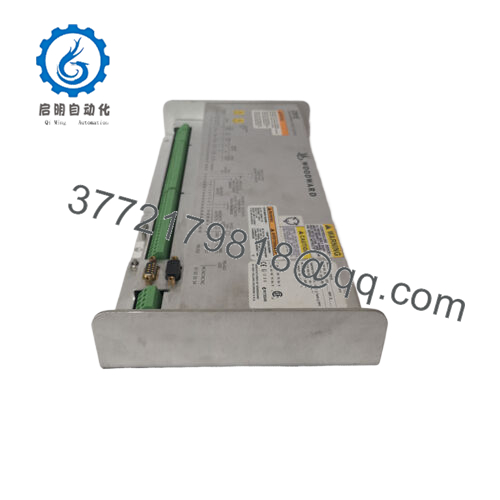

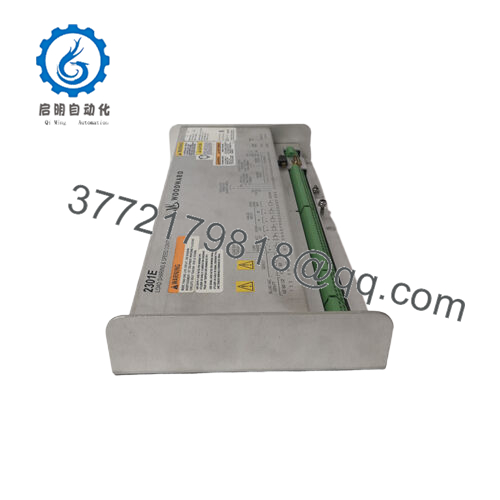

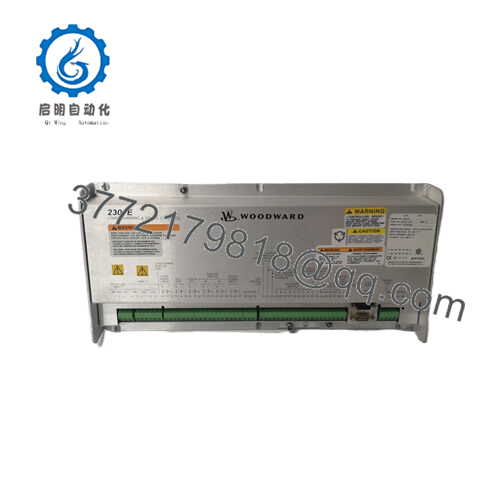

The Woodward 2301E (8273-1011) is a microprocessor-based digital controller that combines functionality from previous 2301A and 2301D models with enhanced software flexibility. It supports configurable application parameters such as engine speed range, gear tooth count, and forward or reverse acting modes through external computer setup using Control Assistant or Woodward ToolKit software.

This module operates from a 24 V DC power supply and includes built-in load sensor circuits, an actuator driver supporting multiple output types (4–20 mA, 0–20 mA, 0–200 mA, or PWM), an MPU speed sensor input, configurable analog I/O, and multiple discrete inputs and relay outputs. With Modbus RTU communication over RS-422 and serial RS-232 ports, the 2301E integrates well into modern control networks.

Key Technical Features & Functional Benefits

The Woodward 2301E offers four operating modes—Speed Control, Isochronous Load Sharing, Droop Base Load, and Isochronous Base Load—providing versatile control strategies to match various operational requirements. Soft load transfer capabilities ease adding or removing units from the bus without disruption.

- 2301E 8273-1011

- 2301E 8273-1011

It incorporates multiple dynamic adjustments, manifold air pressure limiting, torque limiting, and low-speed sensing for enhanced engine protection and performance optimization. Accurate speed regulation is achieved through adaptive sensing algorithms, with a capability for remote speed and load reference input.

Its rugged sheet-metal chassis is suitable for ordinary and hazardous environments, with an operating temperature range from –40 to +70 °C. The control comes configured by external software tools through a 9-pin RS-232 port and supports data logging for events like shutdown and peak load conditions.

Detailed Technical Specifications

| Parameter | Value |

|---|---|

| Model | Woodward 2301E (8273-1011) |

| Brand | Woodward |

| Product Type | Digital Load Sharing & Speed Control Module |

| Input Voltage | 24 V DC |

| Operating Temperature Range | –40°C to +70°C |

| Communication Ports | RS-232 (9-pin), RS-422 Modbus RTU |

| Control Modes | Speed Control, Isochronous Load Sharing, Droop Base Load, Isochronous Base Load |

| Outputs | 1 Actuator Driver (4–20 mA, 0–20 mA, 0–200 mA, or PWM) |

| Inputs | 1 Load Sensor, 1 MPU Speed Sensor, 2 Analog Inputs, 8 Discrete Inputs |

| Relay Outputs | 4 Discrete (Relay Driver) Outputs |

| Enclosure | Sheet-metal chassis |

Related Modules or Compatible Units

Woodward 2301D Load Sharing Control – Predecessor model with similar load sharing and speed functions.

Woodward 723 Plus Digital Control – Advanced digital control for reciprocating engines.

Woodward 828 Digital Control – Control system for reciprocating engines across power and marine applications.

Woodward 9907 Governor Module – Digital engine and generator speed control module.

Woodward 8440 Series I/O Modules – I/O interface modules expanding control system capabilities.

Installation Notes & Maintenance Best Practices

The 2301E should be mounted in a well-ventilated control cabinet with proper grounding and EMI shielding for sensor and communication wiring. Configuration and tuning are performed using Woodward’s Control Assistant or Toolkit software connected through the RS-232 port.

Routine maintenance includes inspecting connectors and wires, monitoring status LEDs, and verifying control and communication signals. Regular software updates and configuration backups enhance reliability and ease diagnostics during operation.

WhatsApp: +86 16626708626

WhatsApp: +86 16626708626 Email:

Email:  Phone: +86 16626708626

Phone: +86 16626708626