Description

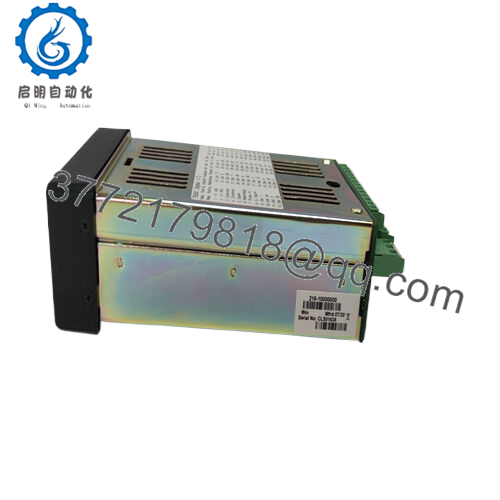

The Watlow CLS216-10000000 is a compact, highly flexible industrial controller widely used across manufacturing, process heating, and automation industries. It serves critical roles where precise temperature, pressure, or flow control is required, such as in plastics processing, food production, and chemical manufacturing. This model addresses the challenges of maintaining consistent process parameters while minimizing manual intervention, ultimately improving product quality and operational efficiency in industrial automation environments.

The CLS216-10000000 is part of Watlow’s compact CLS200 series, which supports PID control of up to 16 independent loops within a single controller platform. Engineered for integration into control panels or sub-panels, it features multiple sensor input options, including thermocouples and RTDs, which allow versatile process variable measurements. Communication capabilities via Modbus TCP/IP and EtherNet/IP protocols make the unit suitable for modern networked control systems, enhancing data acquisition and remote monitoring for engineers and integrators.

- CLS216-10000000

- CLS216-10000000

Key technical benefits of this controller include advanced autotuning PID algorithms, reducing the time and expertise required for setup while ensuring stable process control. Its intuitive 4.3-inch color TFT display offers clear, user-friendly visualization of process states and configuration menus. The controller supports enhanced control functions such as cascade control, ratio control, and process variable retransmit, essential features for complex batch processing and sequence management. Its design adheres to UL and CE standards, ensuring compliance with industrial safety regulations for global deployment.

| Parameter | Value |

|---|---|

| Model | CLS216-10000000 |

| Brand | Watlow |

| Type | Industrial Multi-loop PID Controller |

| Control Loops | Up to 16 loops |

| Display | 4.3” Color TFT |

| Sensor Inputs | Thermocouple, RTD, Linear voltage and current |

| Communication Protocols | Modbus TCP/IP, EtherNet/IP |

| Power Supply | 15 to 24 V DC |

| Operating Temperature | 0°C to 55°C |

| Control Functions | PID, autotune, cascade, ratio, retransmit |

| Certification | UL, CE |

| Mounting | 1/8 DIN Panel or Sub-panel |

| Application | Process control in industrial automation systems |

Related models include the Watlow CLS204 (4-loop controller), CLS208 (8-loop controller), and the enhanced CLS216 variants with special firmware for extruder and ramp-and-soak applications. Each model caters to different control complexity and application needs.

Installation requires sufficient panel space, proper ventilation, and adherence to wiring and grounding guidelines to prevent electrical noise. Maintenance best practices include regular calibration of sensors, firmware updates, and monitoring control loop performance to sustain optimal process stability.

WhatsApp: +86 16626708626

WhatsApp: +86 16626708626 Email:

Email:  Phone: +86 16626708626

Phone: +86 16626708626