Description

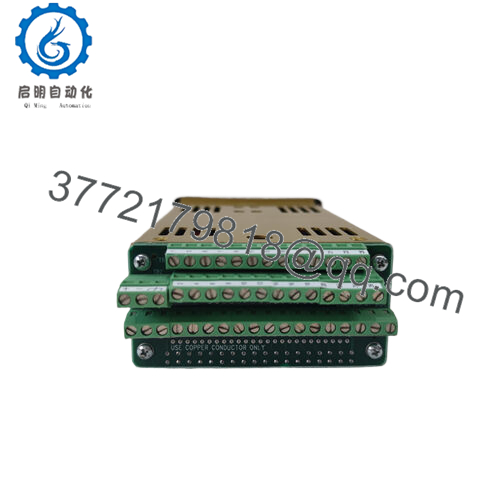

Product Model: CLS208 208-C10000CA

Product Brand: Watlow (Anafaze / CLS series)

Product Series / Platform: CLS200 / Anafaze multiloop controllers

Product Features:

- Modular multiloop controller (supports multiple control circuits, e.g. 8 or 16)

- Accepts diverse input types: thermocouples, RTDs, linear voltage/current, pulse signals

- Digital I/O & network communication (RS-232 / RS-485 / Ethernet) capability for integration

- Compact design with display / keypad interface for local control and diagnostics

- CLS208 208-C10000CA

- CLS208 208-C10000CA

Applications & Industry Context

Temperature control is one of the backbone functions in process and industrial systems. Whether managing multiple furnace zones, drying ovens, heat treatment lines, or chemical reactors, engineers often require robust, reliable multiloop controllers. The CLS208 208-C10000CA is part of Watlow’s Anafaze “CLS200” line, designed to offer flexibility and compact multiloop control options in harsh industrial environments.

In modern facilities, space is precious. Rather than using many discrete single-loop controllers, deploying a module like CLS208 consolidates multiple control circuits into one chassis, reduces wiring, and streamlines maintenance. In retrofit or expansion projects, having a modular controller with multi-circuit capability is much more efficient—it allows you to scale capacity without redesigning the entire control architecture.

Because Watlow’s CLS200 family supports mixed sensor types and multiple I/O modes, the CLS208 variant is versatile—usable in heat, pressure, flow, or other process control tasks beyond just temperature. Many users also take advantage of its communication features to tie process loops into SCADA, DCS, or higher-level control systems.

In many vendor listings, the specific part 208-C10000CA is listed as a multiloop temperature controller in the Anafaze CLS208 series.

Technical Features & Benefits

Here’s a breakdown of what CLS208 208-C10000CA offers, and the benefits those features deliver in real-world use:

Multi-Loop / Multi-Circuit Capability

Watlow’s CLS200 family supports 4, 8, or 16 control loops in a modular structure. The CLS208 variant sits in that line, giving you a compact “bank” of multiple controllers in one unit.

Benefit: fewer physical modules, consolidated cabling, and synchronized management of multiple zones.

Versatile Input Handling

CLS208 units support various sensor inputs—thermocouples, RTDs, linear voltage or current, and pulse-type signals. These mixed input abilities allow one controller to manage diverse measurement sources.

Benefit: flexibility in system design, fewer dedicated converter modules needed.

Digital I/O & Communication

CLS208 includes digital I/O and supports network communications (RS-232, RS-485, Ethernet). Thus, external devices or systems can read status, setpoints, or alarms over a field network.

Benefit: remote monitoring, integration with SCADA/DCS, and centralized control.

Local Display / Keypad Interface

A digital display and keypad are included for on-module viewing of process values, alarms, and manual control. This is useful during commissioning, troubleshooting, or local overrides.

Benefit: eliminates the need for constant connection to a host system to check loop states.

Industrial Durability & Diagnostics

The CLS200 line is built for the rigors of industrial environments. It includes sensor fault detection (open/short), input validation, and local diagnostics.

Benefit: faster fault identification, improved uptime, and minimal surprises in service.

Technical Specifications

Below is a compiled table of claimed or typical specifications based on vendor literature and the CLS200 family datasheet. Treat this as indicative rather than authoritative—always verify with official Watlow documentation.

| Specification | Description / Value |

|---|---|

| Model / Part | CLS208 208-C10000CA |

| Controller Family | Watlow Anafaze CLS200 series |

| Loop Support | Up to 8 or 16 circuits (depending on configuration) |

| Sensor Inputs | Thermocouples, RTDs, linear voltage/current, pulse inputs |

| Accuracy / Resolution | High resolution; mixed sources report ±0.001 °C for Type K thermocouples in some product listings |

| Communications | RS-232, RS-485, Ethernet support |

| Digital I/O | Configurable digital inputs / outputs (for alarms, interlocks) |

| Display / Interface | Local display and keypad interface for status and configuration |

| Operating Environment | Industrial conditions; robust design for temperature, noise, etc. (as per CLS200 family datasheet) |

| Power Supply | Internal power required; matches CLS200 family design (check module variant) |

| Fault Diagnostics | Sensor open/short detection, alarm triggers, internal diagnostics |

| Application Scope | Temperature / process control in multi-zone systems, industrial heating control, etc. |

The official Watlow datasheet (for the CLS200 family) confirms many of these capabilities.

Installation & Maintenance Insights

Here are practical tips from field experience for deploying CLS208 208-C10000CA in control systems:

- Mounting & Ventilation

Install in enclosures with proper airflow. Multiple-loop modules can generate heat, so avoid stacking tightly without clearance. - Sensor Wiring Best Practices

Use shielded, twisted-pair wiring for thermocouples or RTDs. Keep wiring away from high-power cables and ground shields at one end only to avoid loops. - Power Stability & Conditioning

Provide a clean, stable supply voltage to the controller. If your plant supply is noisy or subject to dips, add filtering or UPS protection upstream. - Loop Configuration & Tuning

At commissioning, set up each loop’s PID, ramp/soak, or cascade control features. Use auto-tune where available, then refine manually under actual load. - Diagnostic Verification

Validate sensor fault detection by simulating open / short conditions during commissioning to ensure alarms trigger properly. - Firmware / Configuration Backup

Before operation, export or save all configuration and setpoint data, so replacements or recovery are faster if the controller fails. - Periodic Maintenance

Schedule calibration checks, terminal re-tightening, and visual inspection of wiring and connectors to avoid drift or loose contacts. - Spare Strategy

Keep a spare CLS208 208-C10000CA or identical part in inventory with matched firmware. Label clearly and store in controlled conditions. - Network Integration Testing

Test communication links (RS-485, Ethernet) under load, confirm response times, and monitor for packet errors over time. - Redundancy Planning

In critical systems, consider redundant controller strategies or backup communication paths to ensure minimal downtime in case of controller fault.

WhatsApp: +86 16626708626

WhatsApp: +86 16626708626 Email:

Email:  Phone: +86 16626708626

Phone: +86 16626708626