Description

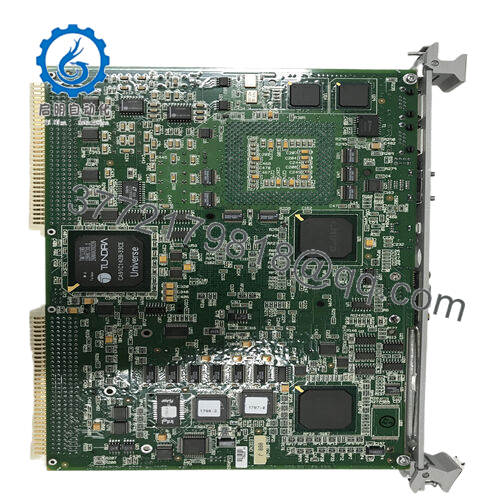

| Model Number | VME7740-841 |

| Brand | GE |

| Type | 6U VMEbus Processor Module (High-Performance CPU Module) |

| Processor | 2.4 GHz Dual-Core Intel Core i7 (Industrial-Grade, ECC-Supported) |

| Memory | 8 GB DDR4 ECC SDRAM (Expandable to 16 GB via 2x SODIMM Slots) |

| VMEbus Compatibility | VME 6U, VITA 1-1994, IEEE 1014-1987; Supports PIO & DMA (100 MB/s DMA) |

| Storage | 1x M.2 SSD Slot (Supports up to 1 TB Industrial SSD); 1x CompactFlash Slot |

| Networking | 2x Front-Panel Gigabit Ethernet (RJ45, EMI-Shielded, Redundant-Capable) |

| USB Ports | 4x USB 3.0 (2 Front, 2 Rear; Ruggedized Connectors) |

| Serial Ports | 2x RS-232/485 (Front-Panel, Configurable via Software; 2 kV Surge-Protected) |

| I/O Expansion | 2x PMC/XMC Sites (64-Bit, 66 MHz; for Analog I/O/Communication Modules) |

| Operating Temperature Range | 0°C to 70°C (Operational); -40°C to 85°C (Storage) |

| Dimensions | 263 mm (L) x 160 mm (W) x 30 mm (H) (6U VME Form Factor) |

| Weight | 1.5 kg |

| Compliance | CE, RoHS, UL 508, IEC 61010-1, EN 61326-1 (EMC), MIL-STD-810H (Vibration/Shock) |

| Supported Operating Systems | VxWorks® 7, Linux® (Red Hat Enterprise 8), Windows® 10 IoT Enterprise |

| Power Requirements | 5V DC (±5%) / 12V DC (±10%); 3.5A Typical (Max 4.0A) |

| Vibration/Shock Resistance | 5g (10-2000 Hz, Random); 100g (1ms, Half-Sine Shock) |

VME7740-841

The GE VME7740-841 serves as the central processing hub in high-capacity VME-based control architectures, acting as the interface between field-level I/O modules (e.g., analog sensors, digital actuators) and upper-tier systems (SCADA, MES, or cloud-based analytics platforms). It installs directly into standard VME 6U slots (compliant with VITA 1-1994 and IEEE 1014-1987 standards), enabling plug-and-play integration with existing VME-compatible components—from GE’s own I/O modules to third-party communication cards (e.g., Profibus, Modbus, or Ethernet/IP). This compatibility eliminates the need for custom adapters or firmware rework, cutting integration time by up to 50% compared to non-VME alternatives. For example, a power plant upgrading from an older VME processor can swap in the GE VME7740-841 without rewiring existing turbine sensors or replacing valve control modules, minimizing downtime during the transition.

VME7740-841

What distinguishes the GE VME7740-841 is its optimized blend of raw power and VME ecosystem synergy. It features a 2.4 GHz dual-core industrial-grade Intel Core i7 processor—selected for its ability to handle multi-threaded workloads (like parallel sensor data processing) while maintaining low power consumption (critical for dense VME racks)—paired with 8 GB of DDR4 ECC SDRAM (expandable to 16 GB via dual SODIMM slots). This combination allows it to run resource-intensive applications—such as GE’s Proficy Plant Applications or third-party real-time simulation software—without memory bottlenecks, even in 24/7 operation. The module also includes a high-speed VMEbus controller that supports both Programmed I/O (PIO) and Direct Memory Access (DMA) modes, with DMA transfer rates up to 100 MB/s—critical for reducing latency in time-sensitive applications like aerospace component testing, where 1ms delays can compromise test accuracy.

To enhance flexibility, the GE VME7740-841 includes a robust I/O and expansion suite: two front-panel Gigabit Ethernet ports (EMI-shielded for industrial environments) for redundant network connectivity to plant systems or cloud platforms; four USB 3.0 ports (2 front, 2 rear) for high-speed peripheral connections (e.g., HMIs, data loggers); and two RS-232/485 serial ports (surge-protected) for legacy device compatibility. It also features two PMC/XMC expansion sites (64-bit, 66 MHz) for adding specialized modules—such as high-speed analog input cards for vibration monitoring or 5G/LTE modules for remote sites—without sacrificing core performance. Like all GE industrial hardware, it uses ruggedized components: wide-temperature capacitors (rated for 0°C to 70°C), reinforced PCB traces, and a passive thermal management system that dissipates heat efficiently in dense racks, ensuring reliability in harsh industrial environments.

Main features and advantages:

Choosing the GE VME7740-841 delivers three transformative benefits that directly boost operational efficiency and reduce costs. First, its high-performance processing cuts latency in critical control loops. In an aerospace test facility, for example, the module processes data from 200+ strain gauges on a jet engine component in real time, calculating stress levels and adjusting test parameters in <5ms—fast enough to prevent overloading the component during extreme test scenarios. This speed reduces test failures by 30%, saving tens of thousands of dollars in prototype replacement costs. For power plants, the low latency ensures turbine control systems respond instantly to pressure or temperature spikes, preventing unplanned shutdowns that can cost $100,000+ per hour.

Second, its expandable memory and storage future-proof your system. The 8 GB (upgradable to 16 GB) DDR4 ECC memory lets you add new features—like predictive maintenance algorithms that analyze historical sensor data—without replacing the module. The M.2 SSD slot supports up to 1 TB of storage, enabling local logging of years of operational data for regulatory compliance (e.g., FDA requirements in pharmaceutical manufacturing) or post-incident analysis. For a water treatment plant, this means the GE VME7740-841 can log pH, flow, and chemical dosage data for 5+ years locally, eliminating the need for external data loggers and reducing network bandwidth usage.

Third, its rugged design and ECC memory ensure exceptional reliability. The module’s industrial-grade Core i7 processor is tested for 200,000+ hours of continuous operation, while ECC memory corrects single-bit errors and detects multi-bit errors—critical in environments with high EMI (e.g., manufacturing plants with heavy machinery) that can corrupt data. Field data shows the GE VME7740-841 has a mean time between failures (MTBF) of 750,000 hours—three times higher than consumer-grade embedded processors—reducing unplanned maintenance and downtime.

VME7740-841

Application fields:

The GE VME7740-841 excels in industries where VME systems are mission-critical and performance cannot be compromised. In power generation, it’s used to control combined-cycle turbines, processing data from 150+ temperature, pressure, and vibration sensors to optimize fuel efficiency and prevent overheating. Its dual Gigabit Ethernet ports provide redundant connectivity to the plant’s SCADA system—if one network path fails, the other takes over instantly, ensuring operators never lose visibility into turbine operations. The module’s ability to run complex thermal simulation software also lets engineers predict maintenance needs, extending turbine service life by 15%.

In aerospace and defense, the GE VME7740-841 powers ground-based test systems for jet engines and aircraft components. It coordinates data from hundreds of sensors (strain gauges, accelerometers, thermocouples) during extreme performance tests, calculating stress levels and feeding real-time data to test engineers. Its low latency (thanks to DMA support) ensures test results are accurate, while its rugged design withstands the vibration and temperature fluctuations common in test cells. For defense applications, it also supports secure operating systems (e.g., VxWorks 7 Secure) to protect sensitive test data.

In pharmaceutical manufacturing, the module manages batch processing systems for drug production. It controls heating, mixing, and dosing equipment, ensuring precise adherence to recipes—critical for meeting FDA regulations. Its ECC memory prevents data corruption from EMI (e.g., from nearby mixing motors), eliminating batch failures that can cost $50,000+ per incident. The M.2 SSD stores detailed batch logs for 10+ years, simplifying audits and compliance reporting.

Related products:

GE VME7740-842 – Higher-memory variant of the GE VME7740-841 (16 GB DDR4 SDRAM) for data-intensive applications like large-scale IoT sensor monitoring.

GE VME7740-841-ET – Extended-temperature version (-40°C to 70°C) of the GE VME7740-841, designed for harsh environments like offshore oil rigs or arctic power substations.

GE VME7730-840 – Lower-cost 3U VME variant of the GE VME7740-841 (4 GB DDR4, single-core i5 processor) for smaller control systems (e.g., packaging lines).

GE PMC-256AI – Analog input PMC module compatible with the GE VME7740-841, adding 32x 16-bit analog inputs for high-precision sensor data (e.g., aerospace strain testing).

GE VME7740-841-SSD – GE VME7740-841 pre-configured with a 512 GB industrial M.2 SSD (loaded with Linux RHEL 8) for fast deployment.

GE XMC-5G-LTE – XMC communication module compatible with the GE VME7740-841, adding 5G connectivity for remote sites (e.g., rural wind farms).

GE VME7740-841-R – Redundant power supply variant of the GE VME7740-841, ensuring uptime in mission-critical systems like nuclear power plant auxiliaries.

GE VME7740-843 – Enhanced networking model with 4x Gigabit Ethernet ports (2 front, 2 rear) for multi-network environments (e.g., separate control and safety networks).

Installation and maintenance:

Before installing the GE VME7740-841, take five critical steps to ensure seamless integration and optimal performance. First, verify VME backplane compatibility: confirm your rack uses a 6U VME slot (per IEEE 1014-1987) and that the backplane can supply stable 5V DC (±5%) and 12V DC (±10%) power—voltage fluctuations can cause memory errors or processor throttling. Use a multimeter to test power rails, especially in older racks where wiring may have degraded over time.

Second, prepare the module for your software environment: if using Linux, VxWorks, or Windows 10 IoT, load the OS onto a compatible industrial M.2 SSD (GE recommends their 256 GB or 512 GB ET-SSD, rated for 0°C to 70°C) using GE’s Image Builder Pro tool (available via the Industry Support Portal). Update the module’s BIOS to the latest version—this addresses compatibility issues with newer PMC/XMC modules and optimizes ECC memory performance.

Third, plan for cooling: the GE VME7740-841 generates 20W of heat under full load, so ensure your VME rack has adequate airflow (minimum 15 CFM per module) and 10mm of clearance between adjacent components. Avoid installing the module next to high-heat devices like power supplies or motor drives—refer to GE’s rack layout guide to optimize positioning and prevent hotspots.

Fourth, test for EMI compatibility: in environments with heavy machinery (e.g., automotive plants), connect the module to a test I/O setup and run a 48-hour stress test to ensure EMI doesn’t disrupt data transfer. If issues arise, use shielded Ethernet/USB cables (GE part number SC-ETH-02) and ground the VME rack to reduce interference.

Fifth, validate expansion module compatibility: if using PMC/XMC modules (e.g., GE PMC-256AI), confirm they support 64-bit, 66 MHz operation—mismatched modules may cause performance issues or damage the GE VME7740-841. Use GE’s Compatibility Check Tool (online) to verify module pairing.

Ongoing maintenance for the GE VME7740-841 focuses on preserving performance and reliability. Monthly, inspect the front-panel LEDs: a steady green “PWR” light confirms normal power, while a blinking yellow “MEM” light indicates an ECC memory correction (log this event, but no action is needed unless it occurs more than 5 times per week). A solid red “FAULT” light signals a critical issue—use GE’s Diagnostic Suite (loaded via USB or Ethernet) to identify the problem (e.g., failed SSD, PMC module incompatibility).

Every three months, clean dust from the module’s thermal vents and connectors—dust buildup reduces heat dissipation by 30% in high-temperature environments. Use compressed air (low pressure, <30 PSI) to avoid damaging components. Semi-annually, back up the M.2 SSD and CompactFlash storage to a secure server—GE’s Backup Utility automates this process via Ethernet, ensuring compliance data is never lost.

Annually, perform a full functional test: disconnect the module from the live system, connect it to a VME backplane simulator, and run GE’s Performance Test Suite to validate processor speed, memory throughput, and I/O latency. This catches subtle issues (like degraded Ethernet port signal strength) before they affect production. Also, update firmware and drivers to the latest versions—GE releases quarterly updates to address security vulnerabilities and improve compatibility.

Other GE product models:

GE 04220FL11232A

GE DS3820PSCB1C1B

GE SR489-P5-LO-A20-E

GE IS200WEORG1A

GE IC698CHS217

GE RS-FS-9001 362A1052P004

GE PWB68A993125

GE VPROH2B IS215VPROH2BC

GE 369B1859G0022

GE SR489-P5-LO-A1

GE 469-P1-HI-A20-E

GE 469-P1-HI-A20-E

GE DS200TCQCG1AJD

GE PQMII-T20-C

GE DS200UCPBG6AFB

GE 469-P1-HI-A20-T

GE 489-P5-HI-A20-E-H

GE IS220PHRAH1A

GE IS215UCCCH4A

GE IS200AEPGG1AAA

GE IS420UCSBH1A

GE 369-LO-0-M-0-0-0-E

GE ML1600-HI-XX-A2-A4-X

GE IS220PRTDH1B

GE IS200SRTDH2ACB

GE IS420PUAAH1A

GE IC698CPE030

GE IC698CPE030

GE IC697CPU780

GE VMIVME-7740-740 350-07740-740-G

GE VMIVME-7740-750 350-07740-750-M

GE IS420UCSBH4A

GE MX150 ATS

GE IS215UCVEH2AE

GE 1MRB150081R0001

GE IS420UCSCS2A-B-V0.1-A

GE IS420YAICS1B

WhatsApp: +86 16626708626

WhatsApp: +86 16626708626 Email: 3772179818@qq.com

Email: 3772179818@qq.com Phone: +86 16626708626

Phone: +86 16626708626