Description

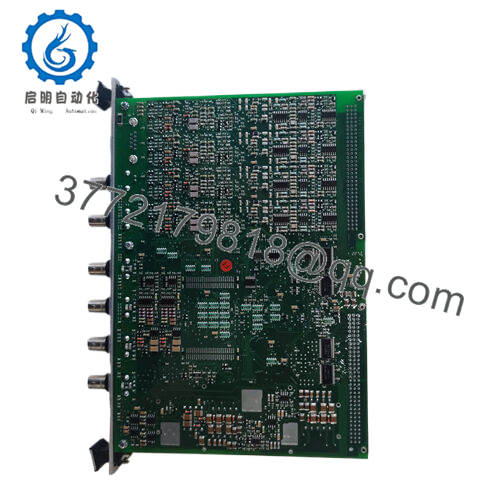

VM600 IOCN 200-566-000-113 is an innovative input/output controller module that is a key driver for seamless integration within the VM600 mechanical protection and monitoring ecosystem. It serves as a communication bridge between on-site devices, including sensors that monitor process variables such as temperature, pressure, and flow, as well as actuators that drive mechanical operations, valve control, and motor regulation.

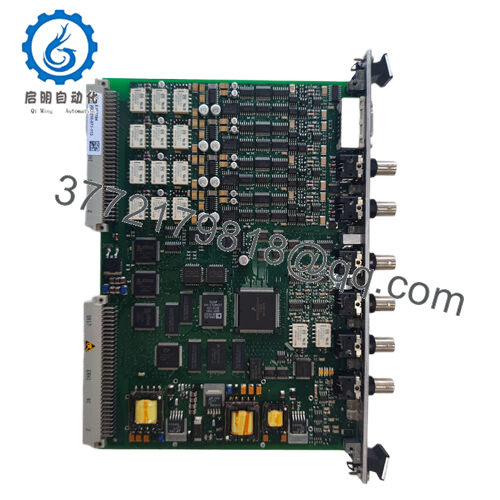

VM600 MPC4 200-510-071-113 200-510-111-034

This module design has high flexibility and adopts a configurable architecture, which can adapt to various industrial scenarios. It can handle a combination of analog and digital input/output signals, and the number of channels can be expanded according to specific application requirements. VM600 IOCN 200-566-000-113 processes incoming sensor data in real-time, applying advanced signal filtering and conditioning algorithms to ensure accurate and reliable data presentation. Then, it packages and transmits the data to the central control system according to industry standard communication protocols such as Modbus TCP, Profibus DP, or EtherNet/IP.

VM600 MPC4 200-510-071-113 200-510-111-034

Technical specifications:

Model VM600 IOCN 200-566-000-113

Brand Vibro meter

Type configurable input/output controller module

Input voltage 24 VDC ± 15%

Working temperature range -25 ° C to 70 ° C

Installation method: DIN rail installation

Dimensions 125mm x 80mm x 45mm

Weight 420g

Interface/Bus Ethernet RS – 485、 Analog input/output, digital input/output

Certified CE, UL, RoHS

Supported protocols Modbus TCP, Profibus DP, EtherNet/IP, OPC UA

Contact Us

Phone:+86 16626708626

WeChat/WhatsApp:+86 16626708626

Email: 3772179818@qq.com

VM600 MPC4 200-510-071-113 200-510-111-034

Main features and advantages:

Its configurable architecture enables enterprises to customize input/output capabilities according to their specific needs, without the need for modules with excessively high specifications or insufficient performance. This not only reduces upfront costs, but also enables enterprises to easily expand when business growth or production demand changes occur.

The high-precision signal processing of this module ensures accurate data acquisition and control, thereby improving product quality and process consistency. In industries with strict quality requirements such as pharmaceuticals or electronics manufacturing, VM600 IOCN 200-566-000-113can help maintain strict production standards by precisely adjusting process variables. The intelligent diagnostic function improves system reliability by implementing predictive maintenance. By detecting potential issues before they escalate, maintenance teams can schedule repairs during planned downtime, minimizing unexpected downtime and related production losses.

In addition, the compatibility of VM600 IOCN 200-566-000-113with multiple industrial protocols simplifies integration with existing and new automation equipment. This future oriented capability enables various industries to adopt emerging technologies without significantly transforming their automation infrastructure. Overall, this module enables enterprises to optimize operations, improve productivity, and gain a competitive advantage in the market.

VM600 MPC4 200-510-071-113 200-510-111-034

Application areas:

In the food and beverage industry, it can be used to manage the input/output signals of sensors that monitor temperature, humidity, and ingredient levels on production lines, as well as to control the actuators of filling machines, packaging equipment, and conveyor belts. Its configurable features enable it to easily adapt to different product formulas and production scales, ensuring stable product quality and efficient production.

In the field of water and wastewater treatment, this module interfaces with sensors that measure water quality parameters such as pH, turbidity, and chemical concentration, and controls actuators that regulate pumps, valves, and treatment processes. Its reliable performance and diagnostic capabilities help ensure the continuous and efficient operation of the processing plant, meeting strict environmental standards.

For the discrete manufacturing industry, VM600 IOCN 200-566-000-113 can achieve seamless integration of various equipment in the factory workshop, from robot assembly units to quality inspection stations. It can handle the complex input/output requirements of these operations, coordinate material flow, control machine motion, and ensure accurate quality control, thereby improving overall manufacturing efficiency.

VM600 MPC4 200-510-071-113 200-510-111-034

Related products:

VM600 IOCN Plus 200-566-000-114: With higher channel scalability and additional advanced features, it is suitable for more complex industrial automation projects.

VM600 IOCN Lite 200-566-000-112: With basic functions and a small number of channels, it is suitable for small industrial applications or users with limited budgets.

VM600 IOCN Pro 200-566-000-115: Designed for mission critical applications, it features faster data processing speeds, enhanced diagnostic capabilities, and support for emerging industrial communication standards.

Installation and maintenance:

Before installing VM600 IOCN 200-566-000-113, it is essential to conduct a comprehensive evaluation of the existing automation system. Confirm that the provided input voltage is within the specified range and the power supply is stable to avoid any electrical issues. Carefully review the communication requirements of the connected devices and ensure that the modules support the corresponding protocols. In addition, when planning the installation layout, consideration should be given to the convenience of future maintenance and protection against environmental factors such as dust and moisture.

During the installation process, please follow the detailed wiring diagram and connection guide provided by the manufacturer. Pay special attention to proper grounding to prevent electrical interference. Clearly label all input and output connections to simplify troubleshooting and future modification work. After installation, conduct a comprehensive system configuration, set input/output channels according to the specific requirements of the industrial process, configure communication parameters, and calibrate sensors and actuators as needed.

For ongoing maintenance, regularly monitor the status indicator lights of the module to detect any signs of abnormal operation. Regularly clean the module to remove dust and debris, especially in environments with high particulate matter content. Install the latest version of firmware provided by the manufacturer in a timely manner, as these updates typically include bug fixes, performance improvements, and security enhancements. If you encounter any problems, please refer to the detailed troubleshooting guide, and if necessary, contact the manufacturer’s technical support team for assistance.

Vibro meter Other product models:

Vibration Monitor AMS3120-A3120/022-000

Vibro-meter VM600 MPC4 200-510-100-034

Vibro-meter 200-566-000-112

VIBRO-METER 200-566-000-112

Vibro-meter 200-582-500-021

VIBRO-METER VM600 RPS6U 200-582-500-013

Vibro-meter VM600 CPUM 200-595-100-014

Vibro-meter VM600 CPUM 200-595-100-014

VIBRO-METER SIM-275A 200-582-500-013

VIBRO-METER VM600 RPS6U 200-582-500-013

VIBRO-METER VM600 CPUM 200-595-100-014

Vibro-Meter VM600MPC4 200-510-017-017

VIBRO-METER MPC4 200-510-078-115

VIBRO-METER MPC4 200-510-077-313

VIBRO-METER RPS6U 200-582-200-021

VIBRO-METER XIO16T 620-002-000-113

Vibro-Meter GSI-127-A2-B2

Vibro-meter GSI127 244-127-000-017-A2-B02

VIBRO-METER VM600 IOCN 200-566-000-113

VIBRO-METER 244-704-000-042-A2-B01-C10-D20-E2-F10000-C0-H0-I0

VIBRO-METER 244-704-000-042-A2-B01-C100-D20-E0.5-F10000-C0-H0-I0

Vibro-Meter VM600 IOCN 200-566-000-113

VIBRO-METER IOC4T-200-560-000-1Hh

VIBRO METER VM600 MPC4 200-510-SSS-1Hh

Vibro-meter 200-510-071-113

Vibro-meter VM600 MPC4

VIBRO-METE IOC8T

VIBRO-METER CMC16 200-530-022-014

Vibro-meter SIM-330A 200-582-500-021

VIBRO-METER VM600 CPU M

VIBRO-METER VM600 MPC4 200-510-071-113

vibro-meter 244-704-000-042

VIBRO-METER SIM-275A 200-582-500-013

WhatsApp: +86 16626708626

WhatsApp: +86 16626708626 Email: 3772179818@qq.com

Email: 3772179818@qq.com Phone: +86 16626708626

Phone: +86 16626708626