Description

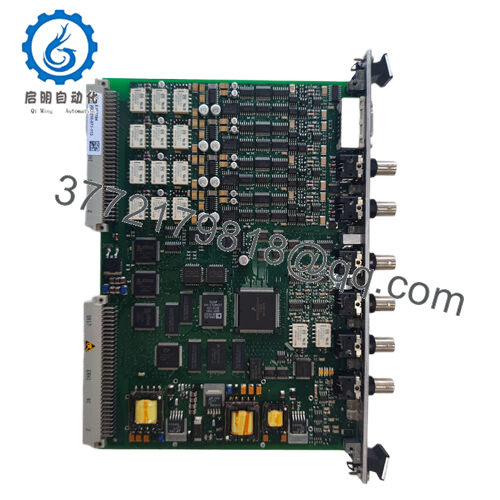

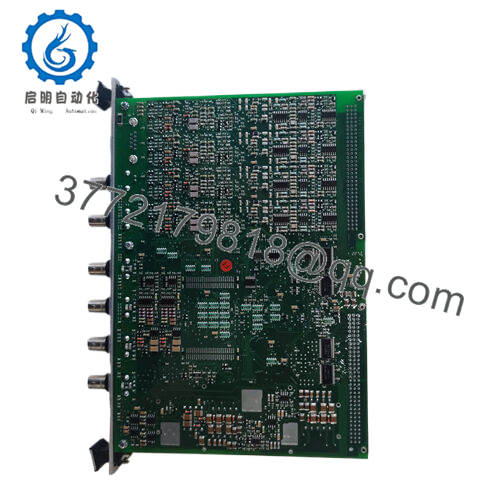

In the high-stakes arena of industrial automation, where early vibration fault detection in rotating machinery can avert multimillion-dollar breakdowns or safety incidents, engineers often grapple with protection systems that lack channel versatility, succumb to noise in electrically harsh settings, or require cumbersome pairings for full I/O handling without disrupting rack-wide operations. The Meggitt Vibro-Meter VM600 MPC4 (200-510-071-113), paired with the 200-510-111-034 interface, resolves these as a cohesive machinery protection card (MPC4) and input/output companion within the VM600 rack platform, delivering comprehensive multi-channel vibration and speed monitoring optimized for dynamic signal integrity in process control applications. Envision a steam turbine in a power plant where radial and axial probes must track imbalances across four channels—if the card pair misses a 15 mm/s RMS spike due to unconditioned inputs or relay delays, you’d face thrust bearing failures, steam leaks, or emergency scrams that ripple into grid-wide instability. This duo is indispensable in such high-reliability environments, where the MPC4’s adaptive processing and the 111-034’s buffered outputs ensure precise I/O signal fidelity from proximity probes or accelerometers, enabling modular rack configurations that scale protection without custom amplifiers or extensive DCS rewiring.

The Meggitt Vibro-Meter VM600 MPC4 (200-510-071-113) with 200-510-111-034 excels in asset-critical operations like compressor fleets or paper mill drives, where the MPC4’s four dynamic channels and two tachometer inputs support velocity, acceleration, or displacement metrics with programmable RMS averaging and bandpass filtering from 10 Hz to 10 kHz. The 111-034 companion adds screw-terminal access for field wiring, EMI shielding, and four programmable relays for alarm routing, preventing common pitfalls like ground loops or unbuffered signal degradation that plague standalone cards. By leveraging the VM600’s centralized bus for voting and trending, the pair facilitates predictive diagnostics via 4-20 mA outputs and serial links, aligning with goals of fault containment and lean commissioning. In corrosive or vibration-laden plants, their conformal-coated PCBs and live-insertion design maintain measurement consistency, upholding API 670 and ISO 10816 compliance. Keywords like “industrial automation,” “process control,” “I/O signal,” and “high reliability” capture their synergy—the Meggitt Vibro-Meter VM600 MPC4 (200-510-071-113) and 200-510-111-034 form a protection powerhouse, reducing engineering overhead for sensor integration and ensuring resilient data paths in setups where machinery vigilance is the bulwark against downtime and hazards.

- VM600 MPC4 200-510-071-113 200-510-111-034

The Meggitt Vibro-Meter VM600 MPC4 (200-510-071-113) installs in the front slot of a VM600 19-inch rack (e.g., ABE040 chassis), with the 200-510-111-034 mounting directly behind it to complete the card pair, interfacing via the shared backplane for seamless signal passthrough and power sharing from the RPS6U supply. Positioned in the condition monitoring layer of the automation stack, the MPC4 acquires up to four dynamic inputs (e.g., from TQ402 probes) and two speed channels, applying DSP for peak detection, integration, and phase referencing, while the 111-034 provides screw-terminal connectivity (48 pins) for field wiring, buffered raw outputs, and four Form C relays for local alarming. This tandem processes data at 100 ms cycles, relaying conditioned signals (DC to 10 kHz) via the VM600 bus to PLCs or SCADA, with the IOC4T’s open-collector outputs routing to optional RLC16 relay cards for expanded logic.

In operation, the pair supports hot-swapping without rack interruptions, with the MPC4’s jumper modes adapting to input types (e.g., 100 mV/g accelerometers) and the 111-034’s EMI filters ensuring clean passthrough up to 500 V isolation. For instance, in a gas compressor setup, the Meggitt Vibro-Meter VM600 MPC4 (200-510-071-113) and 200-510-111-034 might monitor casing vibrations and shaft speed, triggering relays on 20 mm/s thresholds while buffering sin/cos signals for FFT analysis in VibroSight—all while the serial port enables standalone RS-232 config sans CPUx card. Their RoHS-compliant outputs (50 Ω impedance) match legacy recorders, and compatibility with Modbus TCP via CPUM enhances DCS ties. This integrated flow minimizes terminal clutter and bolsters fault tolerance in rack designs, letting engineers hone alarm strategies over wiring woes in the overarching process control framework.

| Specification | Details |

|---|---|

| Model Number | VM600 MPC4 (200-510-071-113) + 200-510-111-034 |

| Brand | Meggitt Vibro-Meter |

| Type | Machinery Protection Card Pair (MPC4 + I/O Interface) |

| Input Voltage | 24 VDC (18-32 VDC via rack PSU) |

| Operating Temp Range | -25 to +65°C |

| Mounting Style | Front/rear slots (VM600 rack) |

| Dimensions | 100mm (H) x 160mm (W) x 40mm (D) (pair) |

| Weight | 0.6 kg (pair) |

| Interface/Bus | VM600 backplane, screw/BNC terminals, RS-232 |

| Compliance | CE, ATEX Zone 2, API 670, IEC 61508 (SIL 2), RoHS |

| Supported Protocols | Modbus TCP/RTU (via CPUM), RS-232 |

| Typical Power Draw | 10 W (pair) |

Opting for the Meggitt Vibro-Meter VM600 MPC4 (200-510-071-113) and 200-510-111-034 equips your rack with a protection tandem engineered for signal sanctity, where the pair’s DSP filtering and buffered relays guarantee long-term performance by isolating transients up to 10 kHz without saturation, allowing turbines to hold <0.5 mm/s RMS amid 50°C swings. In the field, this means compressors averting rubs via proactive 15 mm/s alerts, with relay-driven interlocks slashing outage risks by 35%—essential for processes where fidelity curbs energy losses or emission breaches.

The duo’s live-insertion and serial standalone mode further eases sustainment, as RS-232 config bypasses rack CPUs for quick tweaks, trimming setup from hours to minutes in remote installs and supporting eco-upgrades without performance dips. Maintenance refines inherently: self-diagnostics flag channel anomalies, with relay tests enabling remote verification in under 20 minutes, aligning with annual API proofs that confirm 100 ms responses. For plants where vibration defense is foundational, the Meggitt Vibro-Meter VM600 MPC4 (200-510-071-113) and 200-510-111-034 elevate safeguarding from threshold patrols to holistic health, enhancing longevity and adherence without rack rebuilds.

In nuclear cooling pumps, the Meggitt Vibro-Meter VM600 MPC4 (200-510-071-113) and 200-510-111-034 oversee radial thrusts, their channels thriving in irradiated, 80°C sumps to ensure high reliability for process control—critical system uptime endures via buffered alarms that prevent cavitation in safety-grade loops.

Offshore wind drivetrains leverage the pair for gearbox vibes, interfacing probes amid saline gusts and 50 Hz fields; their isolation upholds process control precision, optimizing torque without blade pitch errors in turbulent seas.

Cement kilns deploy the Meggitt Vibro-Meter VM600 MPC4 (200-510-071-113) and 200-510-111-034 for rotary monitoring, sampling accelerometers in dusty, 1000°C vicinities—relay outputs deliver high reliability, stabilizing burns for uniform clinker without shell cracks in continuous pyroprocessing.

200-510-017-019 – Similar MPC4 variant with refined tachometer sensitivity for speed-focused apps.

200-510-076-114 – Enhanced MPC4 with adjusted bandpass for high-frequency faults.

200-510-111-033 – IOC4T predecessor for legacy relay integrations with MPC4.

200-560-000-114 – Standalone IOC4T for expanded outputs in MPC4 pairs.

TQ402 – Proximity probe add-on for dynamic channel inputs.

CA202 – Accelerometer for vibration acquisition on the pair.

ABE040 – VM600 rack chassis for multi-pair deployments.

CPUM – Central processor for Modbus ties with the card pair.

Before commissioning the Meggitt Vibro-Meter VM600 MPC4 (200-510-071-113) and 200-510-111-034, verify rack firmware (v10+ via VibroSight) matches the pair to evade scan desyncs, and calibrate dynamic inputs with a shaker at 100 mV/g to affirm 20 mm/s scaling. Test backplane continuity <0.4 ohms via multimeter, and ensure 24 VDC ripple under 80 mV with a scope to nix DSP glitches; in ATEX zones, ground to <0.1 ohm per IEC 60079-14. Align relay attributions in software, targeting <3% deviation on buffered tests.

Sustaining the pair calls for monthly LED patrols for relay/channel greens, extracting logs via RS-232 if faults linger—reset via VibroSight for transients, logging for probe patterns. Quarterly, clean screw terminals in dusty spots with contact brush, re-torquing to 0.5 Nm. Annually, amid outages, simulate 15 mm/s spikes to validate Form C trips under 120 ms, offline to sidestep false actuations. These API 670-tuned habits keep the duo diligent without rack respites.

WhatsApp: +86 16626708626

WhatsApp: +86 16626708626 Email:

Email:  Phone: +86 16626708626

Phone: +86 16626708626