Description

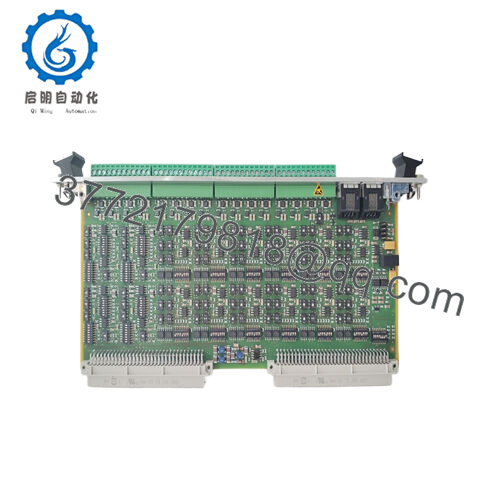

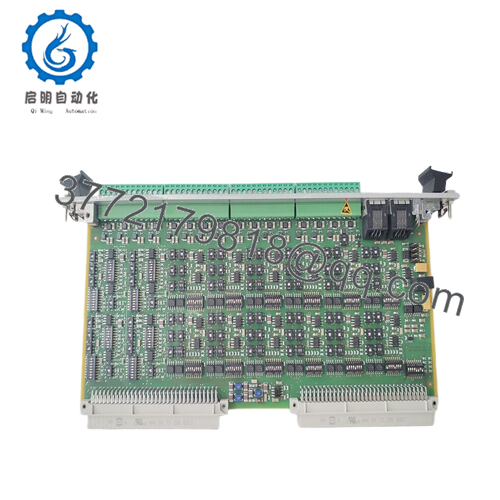

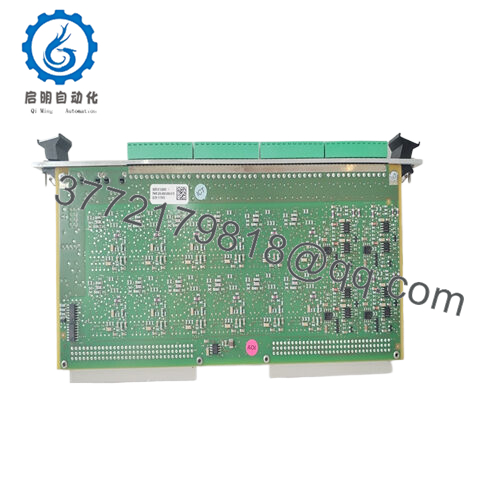

Product Model: VM600 IOC16T

Product Brand: Vibro-Meter (Meggitt)

Product Series: VM600 Machinery Monitoring System

Product Features:

- 16 channels of dynamic (vibration/process) and 4 channels configurable as tachometer

- Signal conditioning, EMI protection, and DIL switch configurability

- Hot-insertion/removal (live insertion) support

- Supports both backplane (raw bus, tacho bus) and isolated RS-485 interface

- VM600 IOC16T

- VM600 IOC16T

When deploying a VM600 rack-based condition monitoring and machinery protection system, the VM600 IOC16T plays a pivotal role as the interface between transducers and the processing modules (e.g. CMC16). It is not a standalone data processing card; rather, it handles the analog and tachometer inputs, conditions them, and routes signals to the core module via backplane or optional serial links.

Mounted directly behind the corresponding monitoring card (CMC16) in the same rack, IOC16T becomes the enabler that allows vibration probes, proximity sensors, tacho encoders, process sensors (e.g. temperature, pressure) to feed their signals into the VM600 ecosystem. Because it supports both signal conditioning and configurable channel roles, it gives system designers flexibility: the first 4 channels may be set as speed (tacho) or dynamic, while the remaining 12 can be dynamic or process inputs. This flexibility is essential in mixed-function racks where one wants to minimize total card count.

In the VM600 architecture, IOC16T is critical to modularity. You can scale a system by adding more monitoring cards and matching I/O cards without redesigning wiring in the field. Also, its backplane connectivity (Raw Bus, Tacho Bus) means you can bypass external cabling for shared signals when desirable, simplifying system layouts.

Because IOC16T serves as the “front end” for measurement inputs, its accuracy, noise immunity, and reliability directly impact the fidelity of vibration diagnostics and protection decisions downstream.

Applications & Industry Context

In heavy industry, the VM600 platform is widely used for protecting turbines, compressors, generators, and other rotating machinery. The IOC16T card is typically found in power plants, oil & gas facilities, petrochemical plants, and large industrial installations where precision vibration monitoring is mandatory under stringent reliability constraints.

For example, in a gas turbine control room, multiple vibration probes, speed sensors, temperature sensors, and process transducers converge into a VM600 rack. The IOC16T receives raw signals from these sensors, conditions them (filtering, level adjustment), protects them against EMI, and forwards them to the central CMC module for analysis. In hydropower applications, where environments are humid and temperature cycles occur, the IOC16T’s robustness ensures signal integrity even under adverse conditions.

In cases where retrofits are necessary—say integrating new sensors into existing VM600 systems—the IOC16T’s flexible input assignment and support for both raw bus wiring and external terminals make it a go-to interface card. Its hot-swappable capability is also a real advantage in high-availability systems, allowing maintenance or replacement with minimal downtime.

Operators often remark that when a system is well designed, the IOC16T is invisible—once installed and configured, it simply becomes the stable signal gateway behind the scenes, rarely needing adjustment or troubleshooting.

Technical Features & Benefits

The IOC16T is more than a passive terminal card. Its features and design choices reflect the needs of harsh industrial settings and strict measurement integrity.

Configurable Channel Roles

Each channel on the IOC16T can be set via DIL switches or configuration bits. The first 4 channels are special: they can be assigned as tachometer (speed/phase reference) or dynamic (vibration) channels. The remaining 12 channels are dynamic or process inputs (voltage, current) depending on application. This grants flexibility, especially when sensor sets evolve over time.

Signal Conditioning and Protection

All input lines incorporate conditioning — pulse shaping, level adjustment, AC/DC coupling, and EMI protection. The card is designed to protect downstream modules from transients and electromagnetic interference. This is indispensable in heavy industrial environments with high electrical noise (switchgear, motors, high voltage lines).

Backplane Bus & Terminal Interface Options

The IOC16T supports both wiring via screw terminal strips and direct signal routing from the VM600 backplane Raw Bus and Tacho Bus. In systems where sensors are cabled into the rack or proximate to it, you can bypass external wiring and reduce field cables. The dual mode is a helpful design flexibility when planning or retrofitting systems.

Communication Options

While the primary use is via the VM600 backplane (connected to CPU or monitoring card), the IOC16T optionally offers isolated RS-485 multi-drop serial communication (supported in certain software versions) for remote diagnostics or signal access. This can be useful in distributed installations where local access is limited.

Hot-Insertion / Hot-Swap Capability

The IOC16T supports live insertion and removal without powering down the rack. This design feature is crucial in systems demanding high availability, reducing the need for full shutdowns during maintenance or upgrades.

Wide Environmental Design

The card is rated for industrial temperature ranges (0 °C to +65 °C) and supports non-condensing humidity conditions. Its physical design is compact and robust, fitting the 6U rack format commonly used in VM600 systems.

These combined features make the IOC16T a dependable, flexible, and essential interface card in VM600 systems.

Technical Specifications Table

| Specification / Parameter | Detail / Value |

|---|---|

| Model | VM600 IOC16T |

| Brand | Vibro-Meter (Meggitt) |

| Module Type | Input/Output (Interface) Card |

| Rack Type | VM600 rack (ABE04x or similar) |

| Mounting Position | Behind CMC16 in rack |

| Channels (Total) | 16 dynamic / process + up to 4 tachometer |

| Tachometer (Speed) Channels | Up to 4 (selectable from first 4 channels) |

| Dynamic / Process Inputs | Analog voltage or current inputs (configurable) |

| Input Voltage Ranges (AC / DC) | 0.1 – tens of V (configurable), ± ranges for DC |

| Current Inputs | Supported (with external resistor) |

| Accuracy | ~1 % FSD for AC, 2 % for DC current (depending on mode) |

| Max Frequency Span | Up to ~20 kHz |

| Input Impedance | ~200 kΩ (voltage inputs) |

| Common-mode Voltage Tolerance | ±50 V (for vibration/process) |

| Communication Interface | VM600 backplane (Raw / Tacho buses), optional RS-485 multi-drop |

| Hot Swap / Live Insertion | Supported |

| Operating Temperature | 0 °C to +65 °C |

| Storage Temperature | –40 °C to +85 °C |

| Dimensions (Height × Width × Depth) | 6U height, ~20 mm width, ~125 mm depth |

| Weight | ~0.30 kg |

| Power Supply (to IOC card) | +5 VDC, +12 VDC, –12 VDC rails |

| Consumption | +5 V rail: ~2 W; +12 V rail: ~1.2 W; –12 V rail: ~1 W (max) |

Installation & Maintenance Insights

Installing a VM600 IOC16T correctly is critical to system reliability. The card is designed to snap into the rack behind its paired monitoring card (CMC16), connecting via two backplane connectors—no external cabling is needed for signals routed over Raw or Tacho buses.

If sensor wiring is external, the IOC16T’s screw terminal strip connectors accommodate direct cable input. During installation, ensure correct shielding and grounding of sensor cables to reduce electromagnetic interference. The card’s own EMI protection helps, but field wiring practices still matter.

When configuring, one should set DIL switches to select each channel’s mode (dynamic, tachometer, process, etc.). Double-check those switch settings before energizing. It’s good practice to validate wiring and channel assignments in a dry run (without full power) to detect miswiring early.

Because it supports live insertion/removal, you can replace a faulty IOC16T card without disturbing other modules in the rack. Always follow safe handling procedures: wear anti-static gear, confirm that the replacement card matches revision, and ensure the rack is in stable power state (though you don’t disconnect main power). Test the new card thoroughly before returning to fully monitored operation.

Routine maintenance includes inspecting connectors for corrosion, verifying that sensor wiring hasn’t loosened, and occasionally exercising channels (e.g. injecting test signals) to confirm signal path integrity. Avoid harsh mechanical shock to the rack during card swaps.

A practical engineer anecdote: In a power plant, a technician replaced a defective IOC16T during a planned maintenance window. Because the card was hot-swappable, other modules remained online, so vibration protection stayed active—and the swap was completed in under ten minutes.

WhatsApp: +86 16626708626

WhatsApp: +86 16626708626 Email:

Email:  Phone: +86 16626708626

Phone: +86 16626708626