Description

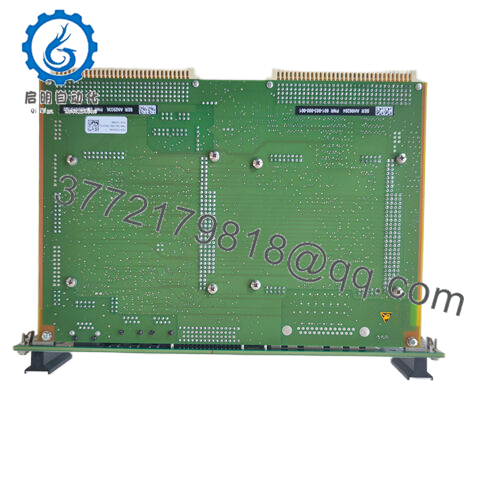

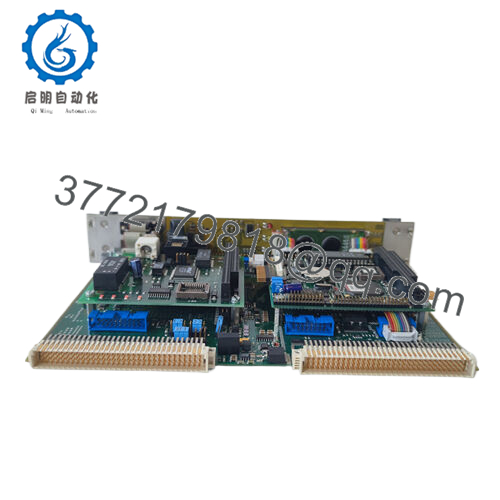

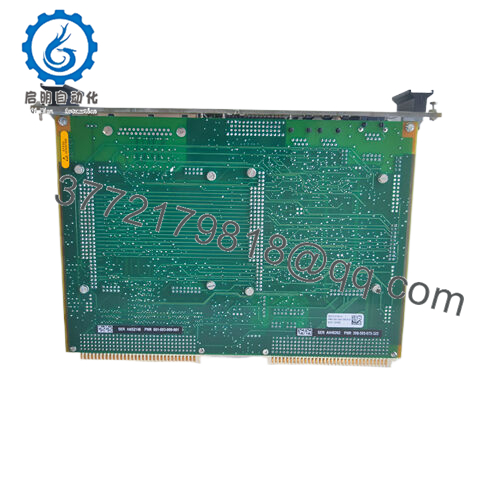

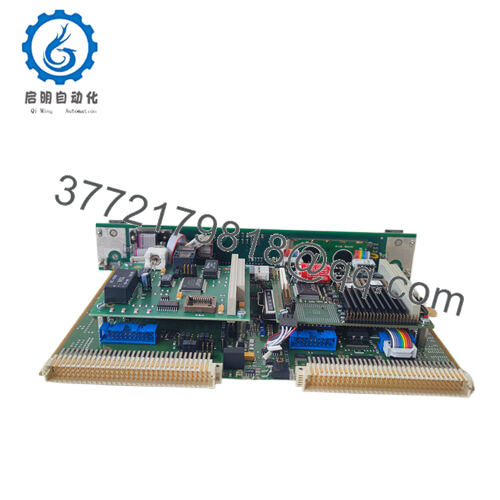

VM600 CPUM 200-595-100-014 is a high-performance central processing unit module for VM600 mechanical protection and monitoring system. It serves as the ‘brain’ of the monitoring system, receiving and processing data from various sensors deployed on industrial equipment, including vibration sensors, temperature probes, and pressure sensors.

VM600 CPUM 200-595-100-014

This module uses advanced algorithms to analyze incoming sensor data in real-time. It can detect subtle patterns and abnormal situations that indicate potential equipment issues, such as bearing degradation, misalignment, or overheating. Once an anomaly is identified, VM600 CPUM 200-595-100-014 will generate detailed alerts and notifications, providing operators with accurate information about the nature and location of the problem.

VM600 CPUM 200-595-100-014

Technical specifications:

Model VM600 CPUM 200-595-100-014

Brand Vibro meter

Type: Mechanical Monitoring Central Processing Unit Module

Input voltage 24 VDC ± 15%

Working temperature range -20 ° C to 65 ° C

Installation method: Rack installation

Dimensions 180mm x 140mm x 60mm

Weight 800g

Interface/Bus Ethernet RS-485

Certified CE, UL, RoHS

Supported protocols Modbus TCP, Profibus DP, EtherNet/IP

Contact Us

Phone:+86 16626708626

WeChat/WhatsApp:+86 16626708626

Email: [email protected]

VM600 CPUM 200-595-100-014

Main features and advantages:

Its advanced data analysis capabilities can detect equipment issues in advance, allowing maintenance teams to schedule repairs during planned downtime. This proactive approach greatly reduces the risk of unexpected failures, minimizes costly downtime, and ensures production continuity.

The seamless integration of this module with existing systems simplifies the monitoring process without the need for complex and decentralized settings. It provides operators with a unified view of the overall health status of the facility equipment, enabling them to make more informed decisions. By reducing reliance on passive maintenance, VM600 CPUM 200-595-100-014 helps extend the service life of industrial machinery, thereby reducing long-term replacement and repair costs.

In addition, the detailed alerts and notifications generated by this module enhance operational security. By promptly notifying operators of potential hazards, it allows for timely intervention, preventing accidents and protecting the safety of personnel and equipment. Overall, this module enables various industries to optimize their maintenance strategies, improve operational efficiency, and gain competitive advantages in the market.

VM600 CPUM 200-595-100-014

Application areas:

In the manufacturing industry, it is used to monitor the health status of large production equipment such as CNC machines, presses, and conveyor systems. By continuously analyzing data from vibration and temperature sensors, it can detect early signs of wear and tear, ensuring smooth production processes and maintaining stable product quality.

In the power generation industry, this module plays a crucial role in monitoring turbines, generators, and other critical electrical equipment. It enables operators to detect rotor imbalance or bearing faults in advance, preventing power outages and ensuring stable power supply. In oil and gas facilities, VM600 CPUM 200-595-100-014monitors pumps, compressors, and motors, helping to maintain effective resource extraction and processing in harsh operating environments while minimizing the risk of equipment failure.

VM600 CPUM 200-595-100-014

Related products:

VM600 CPUM 200-595-100-015: With stronger processing power and larger memory capacity, it is suitable for more complex monitoring applications.

VM600 CPUM Lite: equipped with basic data processing capabilities, suitable for small industrial settings.

VM600 CPUM Pro: Equipped with advanced analysis capabilities, it can achieve more in-depth device health assessments.

VM600 CPUM Plus: a version with additional communication interfaces that can seamlessly integrate with emerging industrial IoT devices.

VM600 CPUM 200-595-100-014

Installation and maintenance:

Before installing , VM600 CPUM 200-595-100-014, it is necessary to ensure that the existing monitoring system is compatible with the module. Verify whether the power supply voltage and communication interface meet the requirements of , VM600 CPUM 200-595-100-014. In addition, carefully plan the installation location to ensure good ventilation and easy maintenance.

During the installation process, please follow the provided wiring diagram and connection guide to ensure accurate and safe connections with other components of the sensor and monitoring system. After installation, perform initial system calibration and configuration, and set alarm thresholds and notification preferences based on the specific requirements of the monitored industrial equipment.

For ongoing maintenance, please regularly check the status indicator lights of , VM600 CPUM 200-595-100-014 to monitor its operational status. Regularly update the firmware of modules to leverage the latest performance improvements, error fixes, and security enhancements. Perform routine data integrity checks to ensure the accuracy of the data being processed and transmitted. If you encounter any problems, please refer to the detailed troubleshooting guide provided by the manufacturer and contact the technical support team if necessary.

Vibro meter Other product models:

Vibration Monitor AMS3120-A3120/022-000

Vibro-meter VM600 MPC4 200-510-100-034

Vibro-meter 200-566-000-112

VIBRO-METER 200-566-000-112

Vibro-meter 200-582-500-021

VIBRO-METER VM600 RPS6U 200-582-500-013

Vibro-meter VM600 CPUM 200-595-100-014

Vibro-meter VM600 CPUM 200-595-100-014

VIBRO-METER SIM-275A 200-582-500-013

VIBRO-METER VM600 RPS6U 200-582-500-013

VIBRO-METER VM600 CPUM 200-595-100-014

Vibro-Meter VM600MPC4 200-510-017-017

VIBRO-METER MPC4 200-510-078-115

VIBRO-METER MPC4 200-510-077-313

VIBRO-METER RPS6U 200-582-200-021

VIBRO-METER XIO16T 620-002-000-113

Vibro-Meter GSI-127-A2-B2

Vibro-meter GSI127 244-127-000-017-A2-B02

VIBRO-METER VM600 IOCN 200-566-000-113

VIBRO-METER 244-704-000-042-A2-B01-C10-D20-E2-F10000-C0-H0-I0

VIBRO-METER 244-704-000-042-A2-B01-C100-D20-E0.5-F10000-C0-H0-I0

Vibro-Meter VM600 IOCN 200-566-000-113

VIBRO-METER IOC4T-200-560-000-1Hh

VIBRO METER VM600 MPC4 200-510-SSS-1Hh

Vibro-meter 200-510-071-113

Vibro-meter VM600 MPC4

VIBRO-METE IOC8T

VIBRO-METER CMC16 200-530-022-014

Vibro-meter SIM-330A 200-582-500-021

VIBRO-METER VM600 CPU M

VIBRO-METER VM600 MPC4 200-510-071-113

vibro-meter 244-704-000-042

VIBRO-METER SIM-275A 200-582-500-013

WhatsApp: +86 16626708626

WhatsApp: +86 16626708626 Email:

Email:  Phone: +86 16626708626

Phone: +86 16626708626