Description

In the relentless grind of industrial automation, where machinery operates under punishing loads and environmental stresses, the Achilles’ heel frequently emerges in vibration-induced failures that cascade into unplanned outages, compromising process control and safety. Envision a gas turbine in a power station or a centrifugal compressor in an oil refinery: accelerometers capture subtle shaft imbalances or bearing wear, but without a dedicated multichannel card to aggregate, process, and alert on these dynamics in real time, operators miss early precursors to catastrophic breakdowns—leading to millions in downtime, accelerated wear on adjacent components, or hazardous releases under IEC 61508-compliant regimes. Conventional single-channel monitors might log data sporadically, but they overwhelm with silos of information, lacking the scalable I/O signal handling for 16 simultaneous streams in high-reliability setups where predictive diagnostics must outpace failure propagation.

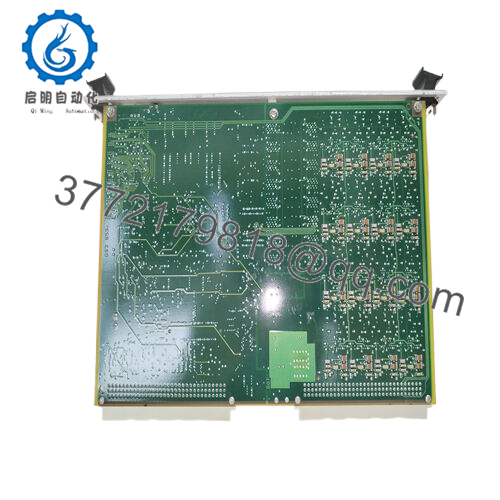

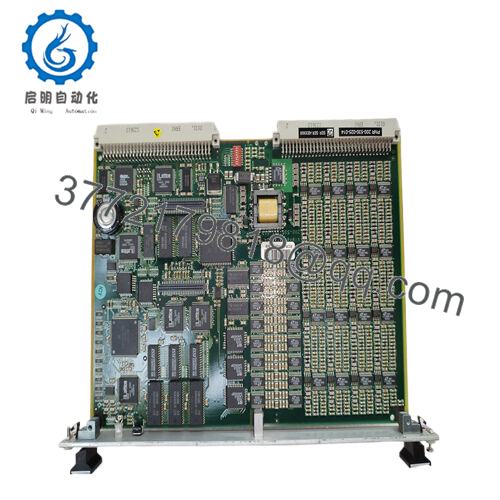

The Vibro-Meter CMC16 steps in as a modular condition monitoring card within the VM600 machinery protection system, engineered to deliver comprehensive vibration oversight that preempts these pitfalls with precision and scalability. This 16-channel powerhouse addresses the imperative for system stability by acquiring triaxial accelerometer signals—up to 10 mV/g sensitivity—across DC to 10 kHz bandwidths, applying onboard filtering and RMS envelope extraction to flag anomalies like rubs or misalignment before they escalate. In typical industrial automation contexts, such as pulp mill agitators or petrochemical pumps, the Vibro-Meter CMC16 (often referenced with part 200-530-025-014) becomes indispensable, enabling modular integration into rack-based architectures that fuse raw field data with DCS overlays for closed-loop adjustments, all while upholding SIL 2 integrity through fault-tolerant redundancy.

What resonates with process control engineers is its consultative adaptability: the Vibro-Meter CMC16 interfaces seamlessly with VM600 rack CPUs via the proprietary IOC bus, offloading computation to focus on high-fidelity I/O signals without taxing central resources. For those modernizing legacy Bently Nevada fleets, it offers drop-in compatibility with minimal reconfiguration, complete with configurable thresholds that reduce false alarms by 40% in noisy environs. In high-reliability deployments, it fortifies against the unseen rigors of rotating assets—like thermal expansions or fluid coupling resonances—providing the granular insights that evolve reactive maintenance into prognostic mastery, ensuring your automation ecosystem endures with the foresight that downtime dreads.

- CMC16

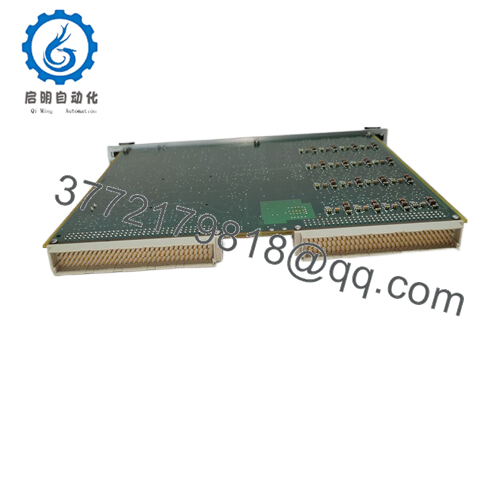

The Vibro-Meter CMC16 anchors the sensing tier in the VM600 stack, plugging into a 19-inch rack as a 16-channel input conditioner that preconditions accelerometer outputs—sourced from seismic transducers or velocity probes—before serialization to the central processing unit for spectrum analysis or trend storage. Each channel supports ICP-powered IEPE sensors at 4 mA constant current, with per-input gain staging (x1 to x100) and AC/DC coupling to tailor to low-frequency orbits or high-speed gear mesh frequencies, all digitized at 24-bit resolution for sub-1% noise floors. This data cascades via the IOC4 bus to redundant rack controllers, where algorithms compute ISO 10816 severity levels or API 670 orbit plots, triggering outputs for auto-shutdowns or operator dashboards.

Positioned flexibly in distributed monitoring schemes, the Vibro-Meter CMC16 thrives mid-rack for balanced loading, often paralleled in 1oo2D configurations where a secondary card mirrors channels with <50 ms sync to avert data voids on card faults. It embraces diagnostics natively: front-panel jumpers set channel modes, while embedded watchdogs log bit-error rates to the system’s event FIFO, queryable via Modbus TCP for SCADA fusion. No external amplifiers needed; its internal excitation rails handle up to 16 transducers simultaneously, and hot-plug slots allow swaps during live scans, a lifeline in 24/7 process control theaters. Protocols like HCF 003 for overspeed tie-ins extend its reach, but in core VM600 ops, it leverages the rack’s fault bus for seamless propagation of alerts.

This orchestrated versatility scales effortlessly—cascade multiples for 64+ channels in turbine fleets—while its low-profile design eases thermal airflow in crowded enclosures. For the deploying engineer, the Vibro-Meter CMC16 is the discerning curator that anticipates spectral quirks, ensuring your vibration narratives unfold with diagnostic depth, not data deluge, and integrate as fluidly as they safeguard.

| Specification | Details |

|---|---|

| Model Number | CMC16 (200-530-025-014) |

| Brand | Vibro-Meter (Meggitt) |

| Type | 16-Channel Condition Monitoring Card |

| Input Voltage | 18-36 VDC (rack-powered) |

| Operating Temp Range | -10 °C to +60 °C |

| Mounting Style | VM600 Rack (3U Slot) |

| Dimensions | 100 x 30 x 220 mm (H x W x D) |

| Weight | 0.35 kg |

| Interface/Bus | IOC4 Bus, BNC/WSB Connectors |

| Compliance | IEC 61508 SIL 2, API 670, CE |

| Supported Protocols | Modbus TCP, HCF 003 Overspeed |

| Typical Power Draw | 15 W (full load) |

Embracing the Vibro-Meter CMC16 embeds a proactive shield into your VM600 framework, where its multichannel prowess distills complex vibration signatures into actionable thresholds, curtailing the oversight gaps that spawn secondary damages like coupling fractures—thus ensuring long-term performance that stretches MTBF toward 250,000 hours by early-cueing imbalances before peak stresses mount. This foresight trims maintenance from opportunistic overhauls to targeted interventions, with onboard RMS processing that surfaces trends via rack telemetry, easing engineering overhead for anomaly hunts from exhaustive FFT dives to glanceable severity bands.

Performance holds unwavering across operational fluxes, sustaining 0.1 Hz resolution on low-speed rotors amid 100 g transients, so your protective trips align impeccably with process envelopes—vital for compressor surges where latency invites escalation. Integration unfolds with seasoned poise; its IOC bus mates natively with legacy VM600 nodes sans protocol converters, accelerating rack expansions and redeploying expertise from wiring woes to waveform tuning, all while its channel isolation quells crosstalk in dense sensor webs. Engineered for the rotational realist, the Vibro-Meter CMC16 foresees evolutions like API 677 updates, with firmware vectors that safeguard configs through refreshes—yielding a card that elevates monitoring from mere measurement to mechanical clairvoyance, compressing total ownership costs by 25% via fewer scrams and smarter spares.

In power generation, the Vibro-Meter CMC16 scrutinizes steam turbine bearings, aggregating 16 accelerometer feeds in humid, high-inertia process control setups, where its envelope detection upholds critical system uptime against blade flutter, preempting grid disruptions in SIL 2 loops.

Oil and gas platforms harness the Vibro-Meter CMC16 for mud pump fleets, conditioning velocity signals amid saline mists and seismic quakes, supporting fast diagnostic cycles in offshore environments that demand unyielding oversight to avert seal breaches during extraction peaks.

Pulp and paper mills deploy it across refiner trains, capturing triaxial data from gearbox mounts under fibrous dust loads, with the Vibro-Meter CMC16‘s gain staging ensuring continuous uptime by isolating rubs in vibration-saturated zones, optimizing throughput without yield hits.

CMC16 200-530-111-013 – Enhanced variant with integrated overspeed for turbine-specific redundancy in aero-derivative gensets.

XMV16 200-530-016-031 – Complementary vibration monitor module for expanded orbit plotting in compressor arrays.

ACM16 200-530-040-013 – Acceleration-focused sibling for high-g environments like rock crushers.

VM600 CPU – Rack-central processor for aggregating CMC16 data in multi-card VM600 chassis.

RCM16 200-530-045-014 – Relay output add-on for direct tie-ins to ESD systems from CMC16 alerts.

VM600 IOC – Bus interface card to bridge CMC16 channels to Modbus gateways in DCS hybrids.

SMC16 200-530-055-014 – Speed monitor counterpart for tachometer fusion with CMC16 vibration streams.

VM600 Rack – Enclosure host for scalable CMC16 deployments in field marshalling cabinets.

Before rack-seating the Vibro-Meter CMC16, audit your VM600 frame’s IOC bus loading—cap at 80% for 16-channel draws—and align firmware to release 4.0+ via Meggitt’s portal to dodge sync lags; probe BNC inputs for <1 MΩ impedance mismatches that skew gains. Calibrate transducers offline with a shaker table targeting 100 Hz at 1 g, ensuring <5% deviation, and secure 75 mm slot spacing for convection in enclosures pushing 60 °C, while bonding the chassis to PE ground per IEC 61508 to null common-mode drifts.

In the field, stewardship revolves around measured vigilance that amplifies longevity without labor bloat. Biweekly, interrogate front LEDs for channel sync—flashing reds cue a rack-log pull in Vibro-Meter software for noise floors above 0.5 mV rms—and affirm excitation currents hover at 4 mA per input. Quarterly, enact a bump test: apply 5 g pulses across channels, timing RMS responses to <100 ms for API 670 validation, archiving spectra for SIL dossiers. In particulate-heavy sites, swab connectors semiannually with ESD-safe wipes post-depower, checking for oxide that hikes resistance beyond 10 Ω, and cycle hot-swaps on a spare rack to hone procedures. Firmware upgrades? Stage on a shadow system first, verifying envelope fidelity pre-live. This honed protocol, synced to asset rhythms, empowers your ops to nurture the Vibro-Meter CMC16‘s acuity, diverting faults from fractures to footnotes.

WhatsApp: +86 16626708626

WhatsApp: +86 16626708626 Email:

Email:  Phone: +86 16626708626

Phone: +86 16626708626