Description

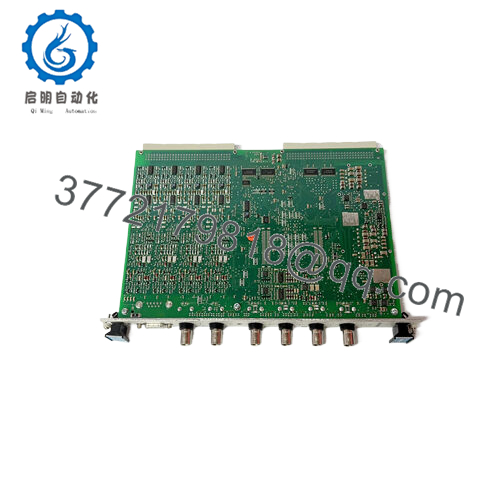

The 200-510-076-114 is the Vibro-Meter MPC4 Multi-Channel Protection Controller, a critical component in advanced machinery protection systems designed for real-time monitoring and fault detection in industrial equipment.

This multi-channel protection card is widely used in industries such as power generation, petrochemical processing, manufacturing, and heavy machinery, where continuous monitoring of vibration, speed, temperature, and other dynamic signals is essential for preventing equipment failures and optimizing maintenance schedules. The 200-510-076-114 MPC4 is suitable for integrating into VM600 rack-based machinery protection systems, providing comprehensive condition monitoring to detect anomalies and avoid unexpected downtime.

Designed to handle four fully independent dynamic signal inputs and two speed sensor inputs simultaneously, this controller supports a wide array of measurements including acceleration, velocity, displacement (proximity), and dynamic pressure. It incorporates digital signal processing functions such as filtering, integration, rectification, and order tracking to analyze complex vibration signals, enabling precise fault diagnosis and robust machinery health assessments.

The MPC4 controller offers sophisticated alarm management with fully programmable alert and danger setpoints, including alarm time delays, hysteresis, and latching options. These adaptive thresholds can be dynamically adjusted based on speed or external variables, enhancing detection sensitivity and operational flexibility. Alarm outputs can drive local relays or communicate over system buses for centralized monitoring.

Its modular design supports live insertion and removal, reducing system downtime during maintenance or upgrades. The unit features self-tests and continuous monitoring functions to verify sensor and signal chain integrity. The controller is available in standard, separate circuits, and safety (SIL) certified versions addressing various industrial safety and functional requirements.

- 200-510-076-114

- 200-510-076-114

| Parameter | Value |

|---|---|

| Model | 200-510-076-114 (MPC4) |

| Brand | Vibro-Meter (Meggitt) |

| Product Type | Multi-Channel Machinery Protection Controller |

| Number of Channels | 4 dynamic inputs, 2 speed inputs |

| Measurement Range | Acceleration, velocity, displacement, dynamic pressure |

| Input Voltage | 24 V DC |

| Digital Processing | Filtering, integration, rectification, order tracking |

| Alarm Management | Programmable alert & danger setpoints, adjustable via speed |

| Communication Protocols | Modbus RTU, compatible with VM600 rack system |

| Operating Temperature | Industrial standard range |

| Certifications | SIL 2, IEC 61508, ISO 13849 |

| Dimensions | 16 cm x 16 cm x 12 cm |

| Weight | Approx. 0.8 kg |

Related Products or Compatible Units

IOC4T – Input/output card pairing with MPC4 for alarm relay handling.

RLC16 – Relay card used for external alarm actuation in machinery protection systems.

IQS450 – Smart vibration sensor compatible with MPC4 inputs.

VM600 Rack System – Modular rack platform supporting MPC4 cards and other monitoring modules.

GSI127 – Galvanic separation units to protect sensor inputs in hazardous environments.

Installation of the 200-510-076-114 MPC4 requires integration into VM600 monitoring racks, with careful attention to secure mechanical fastening and proper electrical connections to sensor inputs and speed signals. Shielding and grounding techniques are critical to preserving signal integrity in noisy industrial environments.

Maintenance focuses on verifying alarm configurations, inspecting sensor and signal quality via system diagnostics, and applying firmware updates to maintain functional safety compliance. Regular testing and recalibration prevent false alarms and ensure continued reliable operation.

WhatsApp: +86 16626708626

WhatsApp: +86 16626708626 Email:

Email:  Phone: +86 16626708626

Phone: +86 16626708626