Description

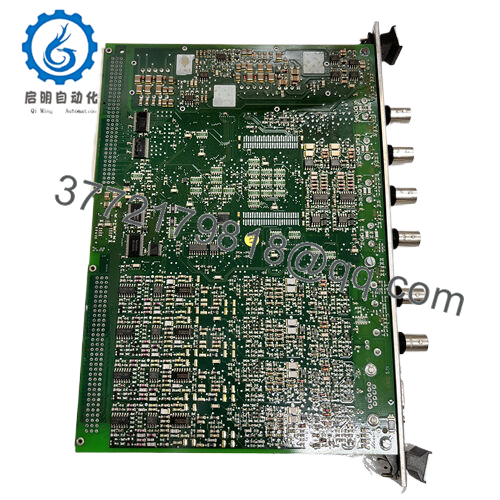

Vibro-meter 200-510-070-113 is a high-precision vibration monitoring module. It is equipped with advanced sensors that can detect small vibrations in industrial equipment such as motors, turbines, and pumps. This module continuously collects vibration data and analyzes parameters such as amplitude, frequency, and phase. Then, it converts the raw data into a standardized format and transmits it to the central monitoring system or control unit. With its high sensitivity and accuracy, 200-510-070-113 can identify early signs of imbalance, misalignment, or bearing wear, and take timely maintenance measures to prevent catastrophic failures from occurring.

200-510-070-113 200-510-111-034 VM600 MPC4

Technical specifications:

200-510-070-113

Vibro-meter

Vibration monitoring module

24 VDC

± 15% -25 ° C to 70 ° C D

IN rail installation

110mm x 65mm x 35mm 300g

Analog, digital, Ethernet

CE, RoHS N/A (focusing on data collection)

7W

Contact Us

Phone:+86 16626708626

WeChat/WhatsApp:+86 16626708626

Email: [email protected]

200-510-070-113 200-510-111-034 VM600 MPC4

Main features and advantages:

The high-precision vibration monitoring of Vibro-meter 200-510-070-113can detect equipment problems early, achieve proactive maintenance, and reduce the risk of unexpected failures. This not only minimizes expensive downtime to the greatest extent possible, but also extends the service life of industrial machinery, saving replacement and maintenance costs in the long run.

The precise control capability of 200-510-111-034 optimizes industrial processes, improving efficiency and productivity. By accurately adjusting process variables, it helps ensure consistency in product quality and reduce waste. Its compatibility with multiple protocols simplifies system integration, allowing for easy addition of new devices or upgrading of existing systems, reducing engineering time and costs.

The comprehensive monitoring and diagnostic capabilities of VM600 provide in-depth insights into device health, making maintenance decisions more informed. Its ability to predict potential failures based on data analysis helps maintenance teams schedule repairs during planned downtime, further reducing disruptions to production. The integration with other systems also promotes the implementation of advanced maintenance strategies, such as state based maintenance, which improves the reliability of the entire factory.

MPC4 simplifies communication in industrial automation networks, eliminates the need for multiple protocol converters, and reduces system complexity. Its reliable data transmission ensures seamless operation of connected devices and improves overall system performance. The ability to support multiple protocols makes automation systems adaptable to the future and easier to integrate emerging technologies. This has led to a more flexible and scalable automation infrastructure, enabling businesses to adapt to constantly changing market demands.

200-510-070-113 200-510-111-034 VM600 MPC4

Application areas:

In the field of power generation, Vibro-meter 200-510-070-113 is used to monitor the vibration of turbines and generators, ensuring their smooth and efficient operation. 200-510-111-034 controls the operation of auxiliary systems such as cooling water pumps and fuel supply systems to optimize the power generation process. VM600 conducts comprehensive monitoring of key equipment, detects early signs of wear and tear, and prevents major faults that may interrupt power supply. MPC4 enables communication between different components of the power plant (from the control room to on-site equipment), ensuring seamless coordination and reliable operation.

In the manufacturing industry, especially in the fields of automotive and aerospace manufacturing, Vibro-meter 200-510-070-113 monitors the vibration of high-speed machining tools and robotic arms to ensure the accuracy and quality of production. 200-510-111-034 controls the movement and operation of production equipment, optimizing the assembly line process. VM600 tracks the health status of large motors and gearboxes to prevent production interruptions caused by unexpected failures. MPC4 integrates different automation systems in the factory workshop to achieve real-time data exchange and improve overall production efficiency.

For the oil and gas industry, Vibro-meter200-510-070-113 monitors the vibration of pumps, compressors, and other rotating equipment in oil well platforms and refineries to ensure their reliable operation in harsh environments. 200-510-111-034 controls the flow of oil and natural gas, regulates pressure and flow rate, and ensures safe and efficient production. VM600 provides early warning of potential equipment failures, helping to avoid costly downtime and safety incidents. MPC4 enables communication between different control systems and equipment in oil and gas infrastructure, ensuring seamless operation and effective production process management.

200-510-070-113 200-510-111-034 VM600 MPC4

Related products:

Vibro-meter 200-510-070-114-200-510-070-113 features enhanced vibration analysis algorithms and additional sensor input channels

A more powerful variant of 200-510-111-035-200-510-111-034, with faster processing speed and larger memory capacity, suitable for more complex control tasks

Advanced models of VM610-VM600 with extended monitoring capabilities, including support for more sensor types and enhanced predictive analysis capabilities

MPC5- Next Generation Multi Protocol Controller, supporting emerging industrial protocols and improved network security features

Installation and maintenance:

Before installing Vibro-meterr200-510-070-113 200-510-111-034, VM600, and MPC4, careful installation planning must be carried out according to the specific requirements of industrial applications. For Vibro-meter 200-510-070-113, ensure that the vibration sensor is correctly installed in the recommended position on the device to obtain accurate readings. Verify the compatibility of input voltage and communication interface with existing monitoring systems.

When installing 200-510-111-034, check the wiring connections to ensure that the signal transmission between the control module, sensors, and actuators is normal. Configure control algorithms according to specific process requirements and conduct thorough testing to ensure accurate control.

For VM600, choose a suitable installation location to install the monitoring unit and ensure that all connected sensors are properly calibrated before debugging. Set alarm thresholds and notification settings based on the normal operating parameters of the device.

When installing MPC4, configure the communication protocol to match the devices in the automation network. Test data transmission between different devices to ensure seamless communication. It is also recommended to update the firmware of all these products to the latest version provided by the manufacturer to benefit from the latest features, performance improvements, and security patches.

For continuous maintenance, regularly check the status indicator lights of each device to monitor its operating condition. For Vibro-meterr200-510-070-113 , regularly calibrate the vibration sensor to maintain accuracy. For 200-510-111-034, check the control performance and adjust the algorithm as needed. For VM600, regularly review monitoring data to identify any emerging trends or potential issues. For MPC4, monitor communication quality and check for signs of data loss or protocol errors. Keep the equipment clean, away from dust and debris, especially in harsh industrial environments.

WhatsApp: +86 16626708626

WhatsApp: +86 16626708626 Email:

Email:  Phone: +86 16626708626

Phone: +86 16626708626