Description

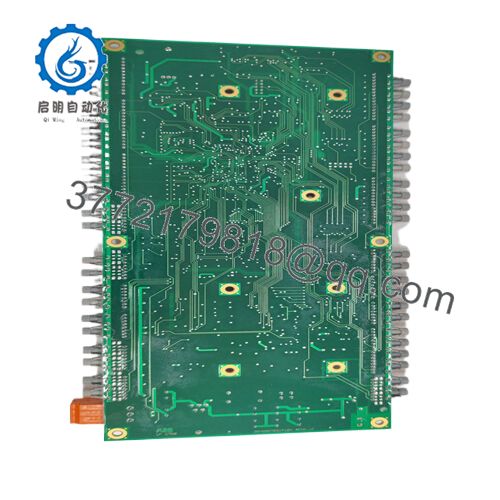

UFC760BE143 3BHE004573R0143 Product Description:

UFC760BE143 3BHE004573R0143 is a cutting-edge control and communication module that serves as an intelligent guardian for industrial automation systems. It is connected to the automation stack through a high-speed, dual redundant bus, ensuring seamless and reliable data transmission between field devices, sensors, and central control units even in the presence of electrical interference or data load fluctuations.

UFC760BE143 3BHE004573R0143

This module supports industry standard protocols such as Profibus, Modbus TCP, and Ethernet/IP, ensuring compatibility with various existing devices. The unique feature of UFC760BE143 3BHE004573R0143 lies in its advanced predictive maintenance capability. It is equipped with complex algorithms and machine learning models that can continuously analyze data from connected sensors and devices to detect patterns and abnormal situations indicating potential faults. For example, it can monitor parameters such as temperature, vibration, and current in real-time, and predict when the motor may overheat or when bearings may be about to fail.

The integrated diagnostic function can provide detailed insights into the performance of the module itself and the health status of the connected devices. Once any potential issues arise, it will immediately send an alert to the control system with actionable maintenance recommendations. Its modular design combined with hot swappable functionality allows for easy upgrades and maintenance without interrupting ongoing operations. Whether integrated into new automation projects or retrofitted into existing settings, UFC760BE143 3BHE004573R0143 seamlessly integrates into the industrial automation ecosystem, enhancing its overall resilience.

UFC760BE143 3BHE004573R0143

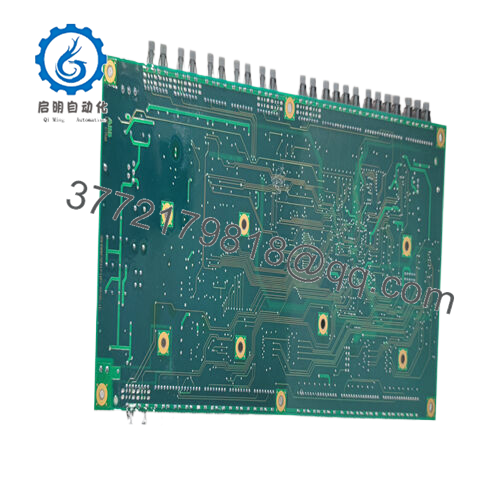

Technical specifications:

Model UFC760BE143 3BHE004573R0143

Brand ABB

Control and communication module with predictive maintenance function

Interface/bus high-speed, dual redundant bus

Supports protocols Profibus, Modbus TCP, Ethernet/IP

Contact Us

Phone:+86 16626708626

WeChat/WhatsApp:+86 16626708626

Email: [email protected]

UFC760BE143 3BHE004573R0143

Main features and advantages:

Choosing UFC760BE143 3BHE004573R0143 can bring significant practical advantages to industrial operations. Its predictive maintenance function enables the company to schedule maintenance activities during planned downtime, reducing unplanned downtime by up to [X]%. In manufacturing plants, this means that production plans are less disrupted, resulting in increased output and improved customer satisfaction. By identifying and resolving issues before they lead to failure, this module can also extend the lifespan of connected devices, reduce the need for premature replacement, and save capital expenditures.

The enhanced diagnostic function of UFC760BE143 3BHE004573R0143 simplifies the troubleshooting process. The maintenance team does not need to spend hours searching for the root cause of problems, but can rely on detailed reports from modules to quickly identify and solve problems, thereby significantly reducing maintenance time and costs. It supports multiple communication protocols, making it easy to integrate into existing systems and reduce engineering costs. The hot plug function ensures that any necessary upgrades or repairs can be carried out without stopping production, maintaining operational efficiency. Overall, this module provides a high return on investment by optimizing productivity, reducing maintenance costs, and improving the reliability of industrial automation systems.

UFC760BE143 3BHE004573R0143

Application areas:

UFC760BE143 3BHE004573R0143 is very suitable for wide application in multiple industries. In the mining industry, heavy machinery operates in harsh environments, and this module can monitor the health status of key equipment such as conveyors, crushers, and drilling rigs. By predicting component failures, it helps mining companies avoid costly failures that could disrupt operations and endanger worker safety.

In the field of aviation manufacturing, accuracy and reliability are crucial. This module is used to monitor the performance of automated assembly equipment, ensuring that each component is manufactured and assembled to the highest standards. Its predictive function can prevent unexpected equipment failures, which may delay aircraft production plans and affect delivery schedules.

For continuous process industries such as oil and gas refineries, UFC760BE143 3BHE004573R0143plays a critical role in maintaining the integrity of complex processing systems. It monitors parameters such as pressure, flow rate, and chemical composition in real-time, predicting potential problems in pipelines, reactors, and pumps. This enables refineries to operate more efficiently, reduce the risk of accidents, and ensure a stable supply of refined products.

UFC760BE143 3BHE004573R0143

Related products:

UFC760BE142 3BHE004573R0142: Provides higher processing power and more I/O channels, suitable for data intensive applications, but with less emphasis on predictive maintenance.

UFC760BE141 3BHE004573R0141: A more basic model with standard control and communication functions, suitable for less complex industrial automation settings.

UFC761BE143 3BHE004575R0143: Designed specifically for high security applications, it combines predictive maintenance with enhanced network security features to prevent network threats.

UFC759BE143 3BHE004572R0143: Has basic predictive maintenance capabilities, suitable for small to medium-sized enterprises with limited budgets.

UFC760CE143 3BHE004576R0143: Focused on advanced signal processing for accurate data analysis in noisy industrial environments, complemented by predictive maintenance functionality.

UFC760BE144 3BHE004573R0144: With higher power processing capabilities, it is suitable for applications involving high-power field equipment and predictive maintenance needs.

UFC760BE140 3BHE004573R0140: Suitable for entry-level applications that only require basic control and simple monitoring.

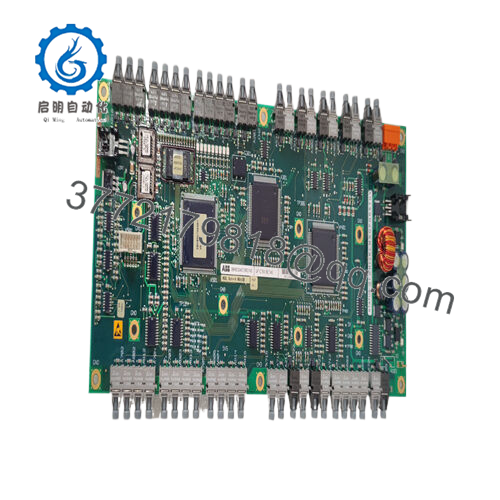

Installation and maintenance:

Before installing UFC760BE143 3BHE004573R0143, it is essential to verify the compatibility of the dual redundant bus with your existing automation system. Ensure that the power supply meets the specific requirements of the module to avoid performance issues or electrical damage. Given its advanced functionality, please ensure that there is sufficient space for proper ventilation in the control cabinet, as the module may generate heat during data intensive operations. In addition, update the firmware of the module to the latest version, as firmware updates typically include improvements to prediction algorithms, security enhancements, and compatibility fixes.

Regularly review the predictive analysis report generated by UFC760BE143 3BHE004573R0143 during daily maintenance to identify potential issues in advance. Check the diagnostic indicator lights to monitor the operating status of the module and the health status of the connected devices. Check for signs of wear, looseness, or corrosion in communication connections, as these can affect the accuracy of data transmission and predictive analysis. Regularly clean the module to remove dust and debris that may interfere with its heat dissipation and electrical functions. Comprehensive annual maintenance should include validating predictive models, calibrating relevant sensors, and ensuring the integrity of communication protocols to maximize the effectiveness of module predictive maintenance capabilities.

Other product models of ABB brand:

ABB UNITROL1020-0006 3BHE030579R0006

ABB UNS 0007a-P.V1, HIEE305098R0001

ABB UNS 4684a-P,V.1 HIEE305114R00R0001

ABB UNS0881b-PV2 3BHE050077R0102

ABB UNS4681V511 3BHE004074R0511

ABB UPC090AE01

ABB USC329AE01 3BHB002482P201

ABB USC329AE01 3bhb002483r0001

ABB USC329AE01 3BHB002483R0001

ABB UUD148AE02 3BHE014185R0002

ABB V18311H-182210100

ABB VIPA972-0DP01 cable

ABB VP01

ABB REM545BG226CAAA 1MRS110024-001

ABB REM615

ABB REM615 REM615E_D

ABB REM615-C HBMCEAGNBCABNN11G

ABB REM615C_E HCMJAEADABC2BNN11E

ABB REM615E_1GHBMBCCAHNEA1ANN11G

ABB REM615-HBMBCCAHNBA1ANN1XD

ABB REM615 panel

ABB REM620 N-B-M-N-AA-AB-AB-B-1-B-N-1-XF

ABB REM630E_C UBMNAAAAABBZAZNAX

ABB RET316

ABB RET-5211MRK001530-AE

ABB RET541AB231AAAA

ABB RET543AB243BAAA

ABB RET543AM243AAAB

ABB RET615F

ABB RET620 NBTNAAAAABC1BNN11G

ABB RET650

ABB RET650 1KHL160055R0001A

ABB RET670 1MRK002816-AC

ABB RET670 1MRK002816-AC

ABB RET670 1MRK002816-AB

WhatsApp: +86 16626708626

WhatsApp: +86 16626708626 Email:

Email:  Phone: +86 16626708626

Phone: +86 16626708626