Description

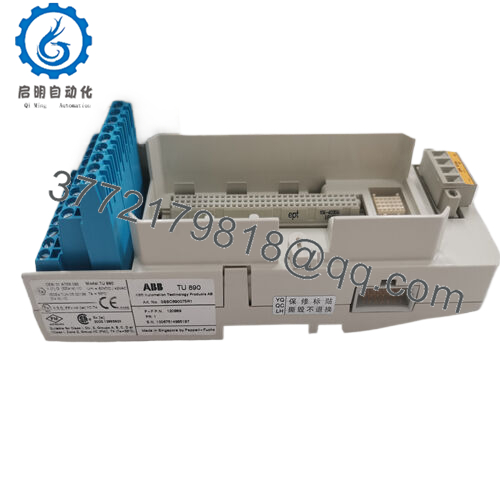

| Model Number | TU890 |

| Brand | ABB |

| Type | Advanced High-Capacity Module Termination Unit (MTU) |

| Maximum Rated Voltage | 75V DC |

| Maximum Rated Current per Channel | 5A |

| Number of I/O Channels Supported | 32 |

| Signal Compatibility | Analog, Digital, and Industrial Ethernet Signals |

| Mounting Style | Heavy-duty DIN rail with enhanced grounding |

| Operating Temperature Range | -30°C to +75°C |

| Storage Temperature Range | -40°C to +85°C |

| Dielectric Strength | 2kV AC for 1 minute |

| Wire Sizes (Solid/Stranded) | 0.2 – 6 mm² / 24 – 10 AWG |

| Recommended Torque | 0.8 – 1.0 Nm |

| Stripping Length | 9 mm |

| Compliance | CE, UL, ATEX, IECEx, ISO 9001 |

TU890

The ABB TU890 is a premium Module Termination Unit (MTU) within ABB’s S800 I/O system, designed to support high-speed communication and advanced signal processing for large-scale automation applications. Its primary function is to manage the interface between field devices and the control system, supporting up to 32 channels to handle high-density signal requirements. Unlike standard termination units, the TU890 integrates native support for industrial Ethernet protocols, enabling real-time data transmission and remote monitoring capabilities that are critical for smart manufacturing environments.

TU890

Positioned at the intersection of field devices and the S800 I/O system’s communication backbone, the ABB TU890 plays a pivotal role in the automation stack. It features advanced mechanical keying to prevent incorrect module installation and ensure system integrity. Mounted on a heavy-duty DIN rail with enhanced grounding mechanisms, it meets the stringent safety requirements of industrial environments, including those with high electrical noise or vibration. The TU890 communicates via both the S800 backplane and Ethernet/IP, providing dual-path redundancy that enhances system reliability in mission-critical applications.

TU890

Main features and advantages:

Selecting the ABB TU890 delivers transformative benefits to industrial operations. Its 32-channel high-capacity design reduces the number of termination units needed in large systems, optimizing cabinet space and lowering installation costs by minimizing wiring complexity. The unit’s advanced Ethernet integration enables seamless connectivity with IIoT platforms, unlocking predictive maintenance capabilities that reduce unplanned downtime—a critical advantage in industries where even minutes of stoppage can incur significant losses.

Engineered for extreme reliability, the ABB TU890 operates flawlessly in harsh environments, from freezing outdoor installations to high-temperature industrial zones, ensuring consistent performance across diverse operating conditions. Maintenance teams gain from its built-in diagnostic tools, which provide real-time alerts for connection issues, signal degradation, or power anomalies, enabling proactive troubleshooting. The unit’s compatibility with ABB’s digital engineering tools also simplifies system configuration and upgrades, reducing engineering overhead and accelerating project timelines.

TU890

Application areas:

The ABB TU890 excels in industries demanding high-channel density, advanced connectivity, and rugged performance. In power generation plants, it connects critical sensors monitoring turbine vibrations, boiler pressures, and generator outputs, leveraging its high-speed Ethernet to deliver real-time data to control systems ensuring grid stability. Its ability to handle high currents makes it ideal for metal processing facilities, where it manages signals from heavy-duty actuators and high-temperature sensors in rolling mills and forges.

In chemical processing plants, the TU890’s ATEX and IECEx certifications make it suitable for hazardous areas, connecting analyzers, valves, and pumps while maintaining safe operation in explosive atmospheres. Water and wastewater treatment facilities also benefit from its scalability, using the 32-channel capacity to monitor multiple treatment stages, from intake filtration to final disinfection, ensuring regulatory compliance and efficient resource management. In all these applications, the ABB TU890 provides the robust connectivity and diagnostic intelligence needed for modern industrial operations.

TU890

Related products:

ABB TU846 – 24-channel termination unit for medium-scale applications requiring balanced density and cost.

ABB S800 I/O AI845 – High-accuracy analog input module optimized for use with TU890 in precision measurement applications.

ABB S800 I/O DO840 – High-power digital output module paired with TU890 for controlling heavy-duty industrial actuators.

ABB TU840V – Explosion-proof variant with reduced channel count for hazardous areas with lower signal requirements.

ABB AC500-S Safety PLC – Safety-rated controller integrating seamlessly with TU890 for SIL 2/3 applications.

ABB S800 I/O PS870 – High-output redundant power supply ensuring uninterrupted operation for TU890 and connected devices.

ABB CI855 – PROFINET interface module enabling TU890 integration with PROFINET-based automation networks.

ABB TB850 – Terminal block extension kit for expanding TU890’s wiring capacity in large-scale installations.

Installation and maintenance:

Before installing the ABB TU890, verify compatibility with existing S800 I/O modules and controller firmware versions to ensure seamless communication. Confirm the DIN rail is securely mounted and rated to support the unit’s weight when fully wired, as the TU890’s robust construction adds moderate weight. Check that the installation environment provides adequate cooling, especially in enclosed cabinets, as high-channel operation generates more heat than smaller termination units. Inspect all wiring for proper gauge compliance and ensure grounding connections meet local safety standards to prevent electrical noise interference.

For ongoing maintenance, regularly review diagnostic data via the control system to identify early signs of signal degradation or connection issues. Inspect terminal blocks quarterly for corrosion, especially in humid or chemical-exposed environments, and retighten connections to the recommended torque if necessary. Perform annual dielectric strength tests to verify insulation integrity, ensuring continued safety compliance. Keep the unit’s firmware updated using ABB’s engineering software to access the latest diagnostic features and performance improvements.

Other ABB product models:

ABB 5SHY4045L0006 3BHB030310R0001

ABB 5SNG015045P0301

ABB 5X00481G04

ABB 61353364D NGDR-03C

ABB 64783785 MP9-20922K

ABB 68311730 MP9-20976K

ABB 70BK03C-E

ABB 70BK06A-E

ABB 70BK06a-E HESG332194R0001

ABB 70EA02A-ES

ABB 70FV01B-E

ABB 750203/80

ABB 750203/806

ABB 802A028D-3

ABB 802A028D-3

ABB 802A028D-3

ABB 81AB03R1210

ABB 81EA04R1210

ABB 83SR04R1210 GJR2390200R1210

ABB 83SR04R1411 GJR2390200R1411

ABB 83SR51R1210

ABB 83SR51R1210

ABB 8502-BI-DP

ABB 87TS01L-E/R1313 GJR2368900R1313

ABB 87ts50-1214

ABB 88TK50R1210

WhatsApp: +86 16626708626

WhatsApp: +86 16626708626 Email:

Email:  Phone: +86 16626708626

Phone: +86 16626708626