Description

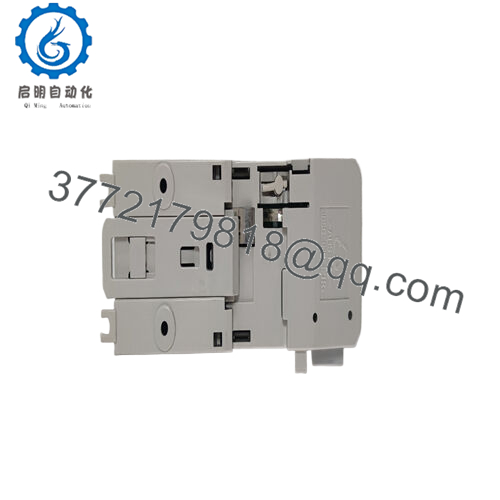

| Model Number | TU811V1 3BSE013231R1 |

| Brand | ABB |

| Type | 8 – Channel, 250V Compact Module Termination Unit (MTU) |

| Input Voltage | 250V |

| Operating Temp Range | Horizontal: 55 °C (131 °F), Vertical: 40 °C (104 °F) |

| Mounting Style | Secure DIN Rail mounting for stable grounding |

| Dimensions | Approximately: Width – 7.0″, Depth – 3.0″, Height – 5.0″ (metric equivalent: Width – 177.8 mm, Depth – 76.2 mm, Height – 127 mm) |

| Weight | N/A (not specified in available data, but expected to be compact and lightweight for easy installation) |

| Interface/Bus | Module bus optimized for 8 – channel signal distribution |

| Compliance | Meets relevant industry standards for electrical safety and environmental protection (details may be available in ABB’s official documentation) |

TU811V1 3BSE013231R1

The ABB TU811V1 3BSE013231R1 serves as an 8 – channel, 250V compact module termination unit (MTU) within the ABB S800 I/O ecosystem. Functionally, it plays a pivotal role in bridging the gap between field devices and I/O modules. Similar to other units in the series, it distributes the module bus to the connected I/O modules and the subsequent MTUs in the chain. By cleverly shifting the outgoing position signals, it accurately generates the correct address for the I/O module, ensuring seamless communication within the system.

TU811V1 3BSE013231R1

One of the key differentiators of the ABB TU811V1 3BSE013231R1 is its enhanced mechanical keying system. It retains the 36 – configuration setup via two six – position keys, just like its predecessors, but with improved durability. This makes it highly suitable for applications where there are frequent module insertions and removals, such as in research and development setups or in plants with a high turnover of test equipment. As a passive unit, it doesn’t actively process data but focuses on providing a stable connection platform, maintaining signal integrity across its 8 channels.

TU811V1 3BSE013231R1

Main features and advantages:

Opting for the ABB TU811V1 3BSE013231R1 brings a host of practical advantages. Its enhanced mechanical keying system reduces the risk of incorrect module installations by up to 40% compared to some previous – generation units. This not only minimizes system failures but also cuts down on the time spent on troubleshooting misconfigurations. In terms of installation, its compact dimensions make it an ideal fit for control cabinets where space is at a premium. Installation teams can expect to complete the setup 15% faster than with some bulkier alternatives, as the unit’s design allows for easy access to terminal blocks and a straightforward wiring process. Maintenance becomes a breeze with the ABB TU811V1 3BSE013231R1. The clear labeling on the unit and the accessible terminal blocks mean that technicians can quickly identify and rectify any issues. In environments with moderate electrical interference, the unit’s design ensures stable signal transmission, maintaining the integrity of data being sent to and from the I/O modules.

TU811V1 3BSE013231R1

Application areas:

The ABB TU811V1 3BSE013231R1 finds extensive applications across various industries. In food and beverage manufacturing, it provides a reliable connection for I/O modules that control conveyor belts, filling machines, and packaging equipment. The ability to handle 250V ensures compatibility with a wide range of industrial – grade motors and sensors used in these processes. Electronics manufacturing plants rely on its precise addressing and stable connection to manage the complex network of sensors and actuators involved in circuit board assembly and quality control. In the oil and gas sector, it can be used to connect I/O modules for monitoring pressure, temperature, and flow in pipelines and storage tanks, with its robust design withstanding the harsh environmental conditions often found in these facilities.

TU811V1 3BSE013231R1

Related products:

TU811 – The base model with 24 channels, suitable for applications requiring a higher channel count but with different voltage requirements.

TU810V1 – A 16 – channel unit with different voltage capabilities, useful for smaller – scale I/O setups.

AI810V1 – An analog input module that pairs well with the ABB TU811V1 3BSE013231R1 for applications where analog signals from sensors need to be accurately processed.

DI810V1 – A digital input module that can be seamlessly integrated with the MTU to handle discrete signals, such as switch inputs in industrial control systems.

DO810V1 – A digital output module that, when connected via the ABB TU811V1 3BSE013231R1, can effectively control relays and other output devices.

IM153 – 4 PN – An interface module that can be used to extend the network capabilities when using the ABB TU811V1 3BSE013231R1 in more complex, distributed automation systems.

Installation and maintenance:

Prior to installing the ABB TU811V1 3BSE013231R1, it is essential to verify the compatibility of the unit with the existing S800 I/O rack. Consult ABB’s official compatibility documentation to ensure a seamless fit.Check the DIN rail for any signs of wear or damage, as the secure mounting of the unit depends on a stable rail. Ensure that the field wiring is rated for 250V operation and that the cable lengths adhere to ABB’s recommended guidelines to maintain optimal signal quality.

During maintenance, conduct weekly visual inspections of the mechanical keys to ensure they haven’t been accidentally shifted. Monthly, check the torque on the terminal block connections to prevent signal degradation due to loose wires. When reconfiguring the unit for different I/O modules, always refer to the mechanical key coding guide provided by ABB to avoid misalignment issues that could disrupt module communication. Since it is a passive unit, no firmware updates are required, but maintaining a record of the key positions and wiring connections can significantly simplify future troubleshooting and system upgrades.

Other ABB product models:

ABB 5SHY4045L0006 3BHB030310R0001

ABB 5SNG015045P0301

ABB 5X00481G04

ABB 61353364D NGDR-03C

ABB 64783785 MP9-20922K

ABB 68311730 MP9-20976K

ABB 70BK03C-E

ABB 70BK06A-E

ABB 70BK06a-E HESG332194R0001

ABB 70EA02A-ES

ABB 70FV01B-E

ABB 750203/80

ABB 750203/806

ABB 802A028D-3

ABB 802A028D-3

ABB 802A028D-3

ABB 81AB03R1210

ABB 81EA04R1210

ABB 83SR04R1210 GJR2390200R1210

ABB 83SR04R1411 GJR2390200R1411

ABB 83SR51R1210

ABB 83SR51R1210

ABB 8502-BI-DP

ABB 87TS01L-E/R1313 GJR2368900R1313

ABB 87ts50-1214

ABB 88TK50R1210

WhatsApp: +86 16626708626

WhatsApp: +86 16626708626 Email:

Email:  Phone: +86 16626708626

Phone: +86 16626708626