Description

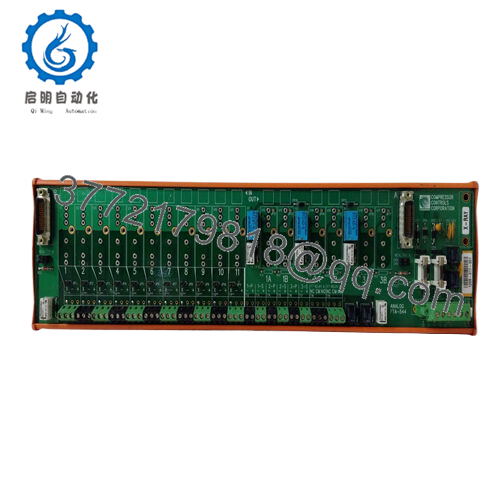

In high-stakes industrial automation setups, where even a brief lapse in output control can cascade into costly shutdowns or safety risks, engineers grapple with ensuring that digital commands translate reliably to field devices like valves, solenoids, or actuators. The Triconex FTA-544 17-550544-001B steps in as a dedicated field termination assembly tailored for output modules, solving the pain points of signal distribution, isolation, and fault tolerance in process control environments. Picture a petrochemical plant where rapid response to process changes is vital—without robust I/O handling, noise from nearby motors or voltage spikes could corrupt commands, leading to erratic actuator behavior or emergency trips. This module becomes indispensable in such scenarios, bridging the gap between the Triconex controller’s processed logic and the physical world, while upholding high reliability standards for I/O signals.

What sets the Triconex FTA-544 17-550544-001B apart is its focus on seamless integration within triple modular redundant (TMR) architectures, where system stability hinges on redundant pathways that prevent single-point failures. It’s a go-to for applications demanding continuous uptime, like emergency shutdown sequences or burner management, where imprecise output delivery might compromise safety integrity levels (SIL). By incorporating isolation barriers and surge protection, it mitigates common threats in industrial automation, such as electromagnetic interference or ground loops, allowing teams to maintain process control without constant recalibration. Keywords like “industrial automation,” “process control,” and “high reliability” underscore its role here—the Triconex FTA-544 17-550544-001B empowers engineers to achieve deterministic performance, reducing the engineering effort needed for custom wiring and diagnostics in modular I/O setups.

- FTA-544 17-550544-001B

Deploying the Triconex FTA-544 17-550544-001B involves connecting it directly to Triconex output modules via standardized connectors, positioning it at the edge of the automation stack where field wiring meets the controller’s backplane. As a termination board, it distributes processed digital signals from the main processor—say, from a 3009 or 3511 output module—across multiple channels to external devices, ensuring each path maintains electrical isolation to avoid cross-talk. In a typical Triconex system, it slots into the I/O subsystem alongside power supplies and communication modules, supporting TMR by mirroring signals across three redundant chassis for fault-tolerant operation. This means if one channel detects an anomaly, the others take over seamlessly, with built-in diagnostics flagging issues via status indicators.

The module’s interaction with protocols like Modbus or proprietary Triconex links keeps data flowing bidirectionally, allowing the controller to monitor output states in real time for closed-loop verification. For instance, in a setup with remote I/O nodes, it handles up to 16 or 32 discrete outputs (depending on the paired module), routing them through screw terminals for easy field connections while complying with intrinsic safety norms. This user-friendly design cuts down on cabling complexity—no need for additional adapters—making it a natural fit for expanding existing systems without disrupting the overall architecture. Overall, the Triconex FTA-544 17-550544-001B enhances the I/O layer’s resilience, enabling faster commissioning and more predictable behavior in environments where every millisecond of response time counts.

| Specification | Details |

|---|---|

| Model Number | FTA-544 17-550544-001B |

| Brand | Triconex (Schneider Electric) |

| Type | Discrete Output Field Termination Assembly |

| Input Voltage | 24V DC (from Triconex I/O module) |

| Operating Temp Range | -40 to +70°C |

| Mounting Style | DIN rail or panel mount |

| Dimensions | 8.5″ x 5″ x 2″ (approx. 216mm x 127mm x 51mm) |

| Weight | 1.2 kg |

| Interface/Bus | 50-pin connector to Triconex I/O |

| Compliance | SIL 3, IEC 61508, ATEX, CE |

| Supported Protocols | Modbus RTU (via host module) |

| Typical Power Draw | <5W (passive termination) |

Opting for the Triconex FTA-544 17-550544-001B delivers tangible gains in operational continuity, as its TMR-compatible design ensures outputs remain active even during module swaps or transient faults, minimizing unplanned outages that could idle production lines for hours. In practice, this means actuators respond with sub-millisecond precision, fostering consistent process control and averting overcorrections that wear equipment prematurely—engineered for the rigors of continuous duty, it safeguards against environmental stressors like dust or humidity, promoting long-term performance without frequent interventions.

The module’s modular termination approach also streamlines maintenance efficiency, letting technicians isolate field wiring from the core controller for targeted testing, which cuts diagnostic time and reduces engineering overhead in large-scale deployments. By embedding surge suppression and optical isolation where needed, it lowers the incidence of false trips, enhancing overall system availability to 99.999% levels typical of SIL 3 applications. Teams benefit from this reliability in ways that extend beyond specs: fewer spare parts on the shelf, quicker root-cause analysis through integrated fault logging, and the confidence to scale automation without proportional increases in complexity. Ultimately, the Triconex FTA-544 17-550544-001B transforms potential vulnerabilities into strengths, supporting leaner operations where safety and throughput coexist.

In oil and gas facilities, the Triconex FTA-544 17-550544-001B is routinely used in emergency shutdown systems, terminating outputs to pilot gas valves under harsh conditions like explosive atmospheres, where its ATEX compliance and high reliability ensure critical system uptime amid vibrations and corrosive elements. This setup handles fast data cycles for real-time valve actuation, preventing overpressure events that could halt refining processes.

Within power generation plants, it supports burner management by routing discrete commands to igniters and dampers, maintaining precise fuel-air ratios in high-temperature environments that demand unwavering signal integrity. The module’s role in process control environments shines here, enabling seamless integration with SCADA overlays for remote oversight.

Chemical processing offers another prime deployment, where the Triconex FTA-544 17-550544-001B manages batch reactor controls, delivering isolated outputs to mixing agitators despite chemical fumes and rapid load shifts—its robust construction guarantees continuous uptime, optimizing yield while adhering to stringent safety protocols.

Triconex 3511 – High-density discrete output module that pairs with FTA-544 for expanded channel capacity in TMR setups.

Triconex 3009 – Enhanced output module alternative with integrated diagnostics for faster fault isolation.

Triconex 9771-210 – Input termination board for balanced I/O architectures, complementing output-focused systems.

Triconex 3700A – TMR analog input module for hybrid signal handling in mixed environments.

Triconex 4351B – Communication module add-on for networked integration with Modbus slaves.

Triconex HCU3700 – Isolated analog output variant for precision current/voltage control upgrades.

Triconex 9563-810 – Terminal block for legacy Tricon systems, serving as a cost-effective retrofit option.

Triconex 3625 – Pulse input module for high-speed applications, extending output sequencing capabilities.

When preparing to install the Triconex FTA-544 17-550544-001B, start by confirming compatibility with your Triconex I/O module—check the connector pinout against the 3511 or 3009 specs to ensure alignment, and verify enclosure ratings match the site’s hazardous area classification. Allocate sufficient DIN rail space, factoring in ventilation to keep ambient temps below 70°C, and review the system’s firmware version for any required updates via Triconex tools. Grounding is key: establish a solid earth reference to leverage the module’s isolation features, and perform a continuity test on field wiring before powering up to catch any shorts.

Maintenance routines for the Triconex FTA-544 17-550544-001B emphasize proactive checks—quarterly inspections of screw terminals for tightness and corrosion, especially in humid or dusty process control areas, using a torque wrench to spec (typically 0.5-0.7 Nm). Monitor output channels with a multimeter during scheduled shutdowns to confirm voltage drops stay under 0.1V, and log any diagnostic flags from the host module for trend analysis. Annual SIL verification testing involves simulating faults to validate redundancy, but keep it straightforward: no full disassembly needed, just connector cleaning with isopropyl alcohol and a soft brush. This disciplined yet minimal regimen aligns with IEC 61508 guidelines, keeping the module in peak form without pulling resources from core operations.

WhatsApp: +86 16626708626

WhatsApp: +86 16626708626 Email:

Email:  Phone: +86 16626708626

Phone: +86 16626708626