Description

The TRICONEX EPI3382 Ethernet interface module is a key enabler of communication in the industrial automation stack. It acts as a gateway, facilitating connections between different devices, control systems, and networks. This module interfaces with programmable logic controllers (PLCs), distributed control systems (DCS), and other field devices to convert their data into a format suitable for Ethernet communication. It supports multiple industrial Ethernet protocols, including Ethernet/IP, Modbus TCP, and PROFINET, ensuring compatibility with a large number of existing automation infrastructure. By utilizing advanced data processing and buffering technologies, EPI3382can ensure reliable and high-speed data transmission even in environments with high network traffic. It seamlessly integrates with the TRICONEX rack system, making it easy to install and configure in complex automation settings. This module also has built-in diagnostic functions that can continuously monitor network health, enabling engineers to quickly identify and solve problems such as network congestion, packet loss, or connection failures.

EPI3382

Technical specifications:

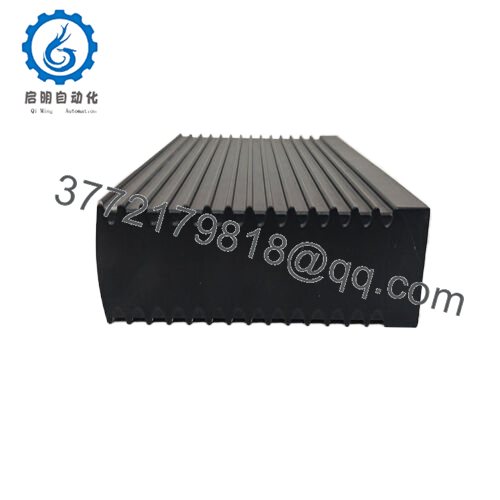

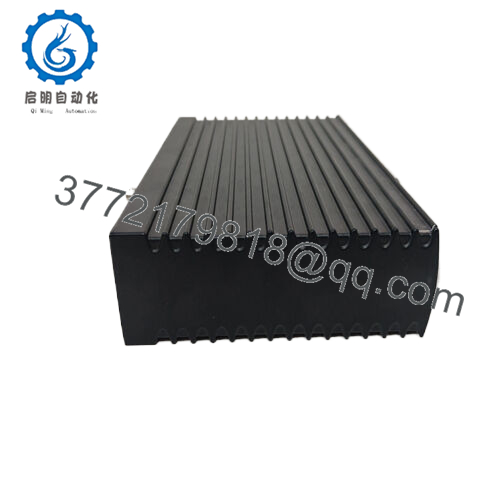

Model EPI3382

Brand Triconex

Type Ethernet interface module

Input voltage 24 VDC

Working temperature range -40 ° C to 70 ° C

Installation method: Rack installation

Size 170 x 110 x 48 millimeters

Weight 1.0 kg

Interface/Bus Ethernet

Compliance with IEC 61508, CE, FM

Supported protocols include Ethernet/IP, Modbus TCP, PROFINET

Data transmission rate up to 1 Gbps

Number of Ethernet ports 4

Network redundancy supports ring networks and Parallel Redundancy Protocol (PRP)

Contact Us

Phone:+86 16626708626

WeChat/WhatsApp:+86 16626708626

Email: 3772179818@qq.com

EPI3382

Main features and advantages:

This module is designed to achieve reliability in harsh industrial environments, ensuring long-term and stable performance even in the presence of high electromagnetic interference, dust, and vibration. Its support for multiple industrial Ethernet protocols simplifies the integration of different devices, reduces the complexity and time required for system setup. For example, in large logistics facilities,EPI3382can easily connect automated guided vehicles, conveyor systems, and inventory management systems to optimize the entire material handling process. The high-speed data transmission capability of this module enables real-time monitoring and control, enabling enterprises to quickly respond to constantly changing production needs and improve overall operational efficiency. The built-in network redundancy function ensures uninterrupted communication and minimizes the risk of system downtime caused by network failures. In addition, comprehensive diagnostic functions facilitate proactive maintenance, allowing engineers to detect and resolve potential issues before they escalate. In the long run, EPI3382will help the industry improve productivity, reduce maintenance costs, and enhance competitiveness in the market.

EPI3382

Application areas:

In the aerospace manufacturing industry, it plays a crucial role in connecting different components of assembly lines, such as CNC machine tools, inspection systems, and robotic work units. By achieving seamless communication, it ensures precise coordination and quality control throughout the entire production process.

In the field of energy, this module is used to connect distributed energy resources such as wind turbines and solar power plants to a central control system. This enables real-time monitoring of energy generation, optimizing power output and grid stability.

In the pharmaceutical industry, strict regulatory requirements require accurate and traceable data transmission. EPI3382ensures that all production equipment, from mixing containers to packaging machines, can communicate effectively, helping to produce high-quality drugs while maintaining compliance. This module can provide reliable and high-speed Ethernet based communication in various industrial applications, making it an ideal choice for any operation that wishes to enhance automation and connectivity.

EPI3382

Related products:

TRICONEX EPI3383: With more Ethernet ports and enhanced data processing capabilities, it is suitable for larger and more data intensive automation applications.

TRICONEX EPI3381: It has basic Ethernet interface functions and is designed for small systems or applications with less demanding communication requirements.

TRICONEX EPI3382H: High temperature resistant variant designed for use in extreme hot environments such as foundries or smelters.

TRICONEX EPI3382R: Redundant module options provide enhanced reliability for critical systems where uninterrupted network communication is crucial to minimize the risk of production interruption caused by module failures.

TRICONEX EPI3382E: With improved signal transmission capabilities, it is suitable for applications that require long-distance Ethernet communication, such as large industrial parks or remote monitoring systems.

TRICONEX EPI3382X: a dedicated module that supports emerging industrial Ethernet protocols and advanced security features, designed to meet the constantly changing needs of modern, interconnected industrial automation environments.

EPI3382

Installation and maintenance:

Before installing the TRICONEX EPI3382 Ethernet interface module, it is essential to thoroughly evaluate the network requirements of the automation system. Verify whether the supported Ethernet protocol matches the protocol of the connected devices and control systems. Ensure that the power supply meets the specifications of the module and has sufficient rack space for proper installation, ensuring good ventilation to prevent overheating. It is also crucial to accurately configure network settings (including IP address, subnet mask, and gateway information) according to the detailed guidelines in the user manual.

For continuous maintenance, regularly monitor the diagnostic indicator lights of the module to detect any network issues or errors. Especially in harsh environments, regularly inspect Ethernet cables and connectors for signs of damage, looseness, or corrosion. Update the firmware of the module to the latest version according to the manufacturer’s recommendations to benefit from performance improvements, security patches, and support for new features. In addition, routine network performance testing is conducted to ensure that data transmission rate and communication reliability meet the requirements of the automation system.

Other product models of Triconex:

TRICONEX 8111

TRICONEX 4351B

TRICONEX 3008

TRICONEX 3625C1

TRICONEX 3503E

TRICONEX 3700A

TRICONEX 3625

TRICONEX 4200

TRICONEX RXM4200-3

TRICONEX 8310

TRICONEX 3626X

TRICONEX MP3101S2

TRICONEX PLM3900N

TRICONEX 8310

Triconex IMFF4703x

TRICONEX 3351S2

Triconex 3603E

Triconex Mar-01

TRICONEX 3401S

TRICONEX 3401S2

TRICONEX 3009

TRICONEX RXM4201

Triconex 3501T

TRICONEX 3503E

TRICONEX 3503E

TRICONEX 3504Е

Triconex 3604E

TRICONEX 3623T

Triconex 3636R

TRICONEX 3704E

TRICONEX 3704Е

TRICONEX 3723X

TRICONEX 3805E

TRICONEX 3805E

TRICONEX 3805E

Triconex 3805E

Triconex 3806E

TRICONEX 8310N2

Triconex 4210

Triconex 4211

TRICONEX 9566-810

TRICONEX 3351S2

TRICONEX 3511

TRICONEX 3664

TRICONEX 3625C1

TRICONEX 3008

Triconex 3607E

TRICONEX 3604E

TRICONEX 3009

TRICONEX 3624

TRICONEX RXM4201

TRICONEX 8310

TRICONEX 4351B

TRICONEX 4351B

TRICONEX 4351B

TRICONEX CIM3211S2

TRICONEX DI3301S2

TRICONEX A03481S2

TRICONEX 3805H

TRICONEX 3506X

TRICONEX 3626X

TRICONEX 4355X

TRICONEX 7400247-020

Triconex 8311

WhatsApp: +86 16626708626

WhatsApp: +86 16626708626 Email: 3772179818@qq.com

Email: 3772179818@qq.com Phone: +86 16626708626

Phone: +86 16626708626