Description

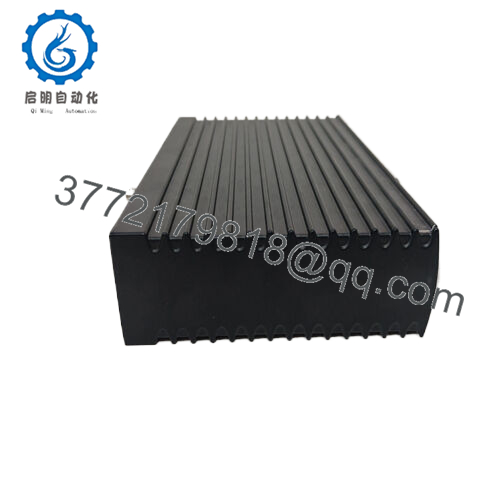

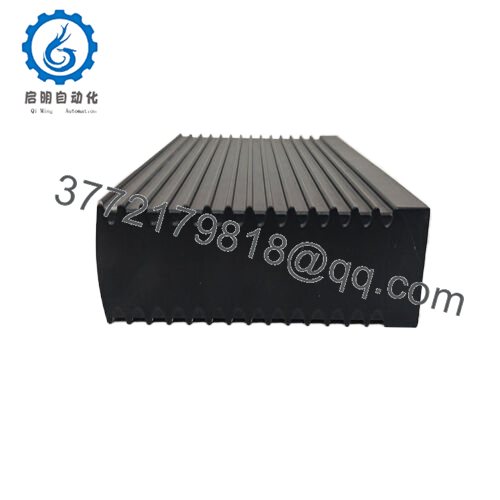

Product Model: EPI3382

Product Brand: Triconex

Product Series: Triconex Safety Instrumented System (SIS)

Product Features:

- Reliable communication interface module for Triconex safety systems

- Designed for robust, fault-tolerant networking and I/O handling

- Hot-swappable module for reduced downtime

- Proven performance in oil & gas, petrochemical, and power generation industries

- EPI3382

- EPI3382

Product Role & System Fit

The Triconex EPI3382 module serves as an essential communication and interface component within the Triconex Safety Instrumented System. In a typical setup, Triconex CPUs handle logic execution, while I/O modules connect to the field. The EPI3382 bridges these layers, ensuring smooth communication and reliable data flow between controllers, I/O cards, and external networks.

Its role extends beyond simple data transfer. The EPI3382 incorporates diagnostics and validation, helping the safety system confirm that information being exchanged is accurate and free from corruption. In triple modular redundant (TMR) architectures, this reliability is non-negotiable.

The module integrates seamlessly with the broader Triconex ecosystem, making it compatible with legacy installations as well as modern expansions. Whether used in emergency shutdown systems, burner management solutions, or turbine protection, the EPI3382 Triconex communication card plays a vital role in linking safety logic to physical actions in the field.

Applications & Industry Context

In the demanding world of process automation, safety systems depend on fast and reliable communication to function. The EPI3382 Triconex module finds its place in industries where seconds matter and downtime is unacceptable.

In oil & gas, it’s deployed on offshore rigs and refineries to ensure safety-critical signals pass without delay between sensors, controllers, and shutdown devices. In petrochemical facilities, it helps synchronize safety interlocks across complex reactor trains or distillation systems. Power plants—whether gas turbine, coal, or nuclear—also rely on the EPI3382 to maintain seamless communication between processors and field equipment.

Real-world stories from the field reinforce its importance. One LNG facility reported that during a planned upgrade, the EPI3382 modules allowed them to expand I/O capacity without halting production, thanks to hot-swap design. Another operator highlighted how its diagnostics flagged a potential communication degradation before it caused system disruption, allowing preventive maintenance and avoiding an emergency trip.

From heavy industry to utilities, the EPI3382 proves itself as a communication backbone for Triconex safety systems worldwide.

Technical Features & Benefits

The Triconex EPI3382 communication module is engineered with several key features that set it apart in the field of safety automation.

First is its robust design. Built with conformal-coated electronics and industrial-grade components, it withstands high humidity, dust, and corrosive atmospheres. This durability ensures reliable operation in offshore platforms, desert installations, and chemical plants alike.

Fault tolerance is another major benefit. The EPI3382 supports redundant configurations, meaning communication remains uninterrupted even if one path fails. Combined with continuous diagnostics, operators gain visibility into module health at all times.

The hot-swap capability is highly valued. Engineers can replace the EPI3382 module without shutting down the system, reducing downtime and maintaining production continuity. Integration with the Triconex TMR architecture ensures that safety logic execution remains uncompromised during maintenance.

Performance is also strong. The module delivers fast, deterministic communication, supporting real-time response required by SIS applications. By maintaining data integrity across critical networks, it helps enforce the strict reliability demanded by functional safety standards such as IEC 61508 and IEC 61511.

For users, the outcome is clear: fewer communication failures, smoother integration, and confidence that safety signals are always delivered.

Technical Specifications Table

| Specification | Detail |

|---|---|

| Product Model | EPI3382 |

| Brand | Triconex |

| Series | Safety Instrumented System (SIS) |

| Function | Communication/Interface Module |

| Architecture Support | TMR (Triple Modular Redundancy) |

| Diagnostics | Built-in continuous self-test |

| Hot-swap Capability | Yes |

| Communication Role | Interfaces processors, I/O, and external networks |

| Environmental Protection | Conformal coated electronics |

| Typical Applications | ESD, BMS, turbine protection, process interlocks |

| Reliability Rating | High availability, fault-tolerant |

| Lifecycle Support | Supported by OEM and global third-party partners |

Installation & Maintenance Insights

Installation of the Triconex EPI3382 module is straightforward but demands proper attention to detail. The card must be fully seated in the chassis with secure terminal and communication connections to ensure vibration does not cause intermittent faults.

For maintenance, the EPI3382 provides built-in diagnostics, offering real-time alerts on module health and communication performance. This makes preventive maintenance easier, as engineers can address issues before they affect operations.

One best practice is to schedule periodic firmware updates and system proof tests, keeping the module aligned with current safety standards. Additionally, operators in remote locations often keep spare EPI3382 cards on hand to minimize mean time to repair (MTTR).

Hot-swappability is another valuable feature. If replacement is needed, the module can be swapped without shutting down the SIS, ensuring that critical plant operations remain online. This reduces both downtime and operational risk in continuous-process facilities.

Related Models

- EPI3381 Triconex Communication Module – earlier version with baseline capabilities

- EIC3050 Triconex Ethernet Interface Card – provides Ethernet connectivity to external systems

- CC3310 Triconex Communication Module – handles control network communication

- DI3351 Triconex Digital Input Module – collects field digital signals for SIS logic

- DO3401 Triconex Digital Output Module – drives actuators and final elements with redundancy

- AO3481 Triconex Analog Output Module – provides analog signals to control valves and regulators

- PS3501 Triconex Power Supply Module – delivers stable redundant power to system racks

WhatsApp: +86 16626708626

WhatsApp: +86 16626708626 Email:

Email:  Phone: +86 16626708626

Phone: +86 16626708626