Description

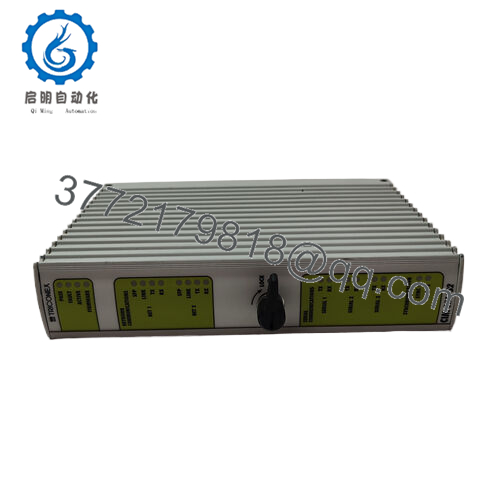

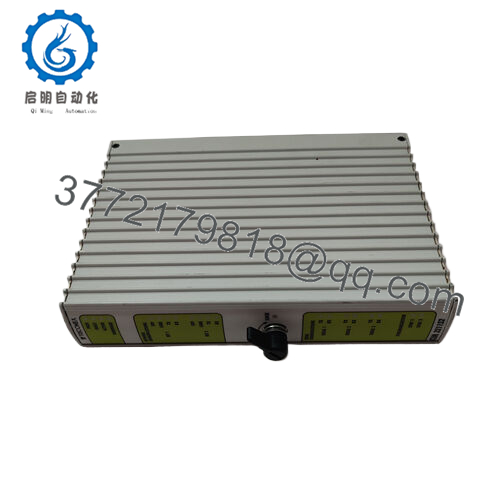

The TRICONEX CIM3211S2 communication interface module is a key communication hub in industrial automation architecture. It is like a bridge that facilitates seamless data exchange between different devices and control platforms. This module can interface with programmable logic controllers (PLCs), distributed control systems (DCS), field devices, and other network components. It supports multiple industry standard communication protocols, including Modbus TCP, Profibus DP, and Ethernet/IP, and can be easily integrated into existing automation infrastructure. With advanced signal processing and error correction techniques, CIM3211S2 can ensure the accuracy and reliability of data transmission even in environments susceptible to electrical noise and interference. This module has built-in diagnostic functions that can continuously monitor communication health status, enabling engineers to quickly identify and resolve issues such as packet loss or protocol errors. It seamlessly integrates with the TRICONEX rack system, improving the overall communication efficiency and reliability of the automation system.

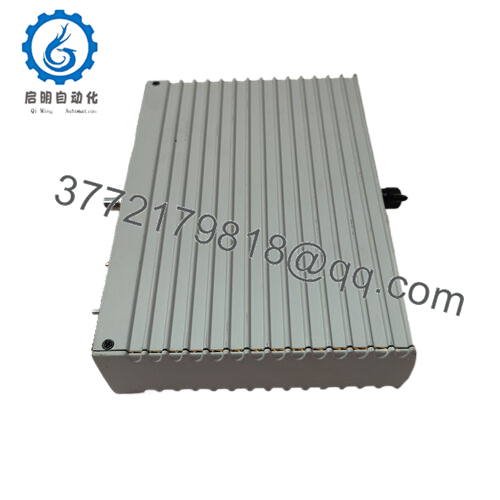

CIM3211S2

Technical specifications:

Model CIM3211S2

Brand Triconex

Type communication interface module

Input voltage 24 VDC

Working temperature range -40 ° C to 70 ° C

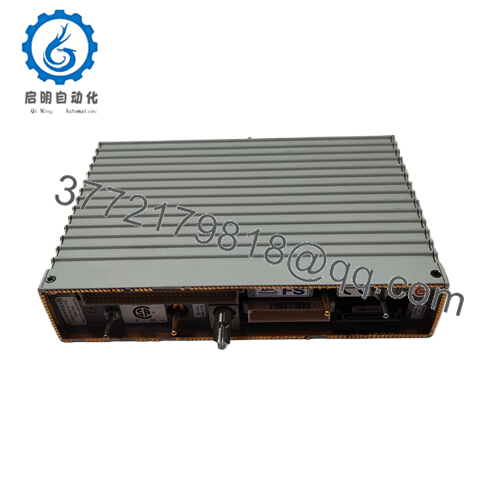

Installation method: Rack installation

Size 180 x 120 x 50 millimeters

Weight 1.1 kilograms

Interface/Bus Ethernet RS – 485、Profibus

Compliance with IEC 61508, CE, FM

Supported protocols Modbus TCP, Profibus DP, Ethernet/IP, HART

The data transmission rate of Ethernet can reach up to 1 Gbps

Number of communication ports 4

Contact Us

Phone:+86 16626708626

WeChat/WhatsApp:+86 16626708626

Email: 3772179818@qq.com

Main features and advantages:

This module is designed to achieve reliability in harsh industrial environments, ensuring long-term, trouble free operation even in the presence of high vibration, dust, and moisture conditions. Its ability to support multiple communication protocols simplifies system integration, reduces the complexity and time required to connect different devices. For example, in large manufacturing plants, CIM3211S2 can easily interface with old equipment and modern intelligent devices, simplifying automation processes. The high-speed data transmission capability of this module enables real-time monitoring and control, improving operational efficiency and response speed. The built-in diagnostic and error correction functions reduce the risk of communication failures, minimize unplanned downtime and maintenance costs. In the long run, CIM3211S2 will help the industry improve productivity, reduce total cost of ownership, and enhance competitiveness in the market.

CIM3211S2

Application areas:

In the automotive manufacturing industry, it plays a crucial role in coordinating communication between robot assembly lines, quality control systems, and material handling equipment. By ensuring seamless data exchange, it can achieve precise and efficient production processes, thereby improving the quality of automotive production.

In the oil and gas industry, this module is used to connect remote sensors and monitoring equipment in oil fields to a central control system. This enables real-time collection and analysis of data, enabling operators to optimize production, detect leaks in a timely manner, and ensure the safety of personnel and the environment. In the pharmaceutical industry, strict regulatory requirements require accurate and reliable data transmission for process control and quality management. CIM3211S2 ensures that all components of the production line can communicate effectively, promoting the production of high-quality drugs.

CIM3211S2

Related products:

TRICONEX CIM3212S2: With more communication ports and higher data transmission capacity, it is suitable for applications with higher requirements.

TRICONEX CIM3210S2: It has basic communication functions and is suitable for small automation systems.

TRICONEX CIM3211S3: Featuring enhanced security features and improved error handling capabilities.

TRICONEX CIM3211SH: Designed specifically for extreme thermal environments.

TRICONEX CIM3211SR: Provides higher reliability for critical systems that require zero downtime.

TRICONEX CIM3211SE: Supports additional communication protocols.

CIM3211S2

Installation and maintenance:

Before installing the TRICONEX CIM3211S2 communication interface module, it is essential to thoroughly evaluate the communication requirements of the automation system. Verify whether the supported protocols match the protocols of the connected devices and control platforms. Ensure that the power supply meets the specifications of the module and has sufficient rack space for proper installation to ensure good ventilation. Follow the detailed instructions in the user manual to accurately configure communication settings, including IP address, baud rate, and protocol parameters.

For continuous maintenance, regularly monitor the diagnostic indicator lights of the module to detect any communication issues or errors. Regularly check the connections between the module and other devices for signs of looseness, corrosion, or damage. Update the firmware of the recommended module to the latest version to benefit from performance improvements and security patches. Regularly clean the module to remove dust and debris that may affect its performance.

Other product models of Triconex:

TRICONEX 8111

TRICONEX 4351B

TRICONEX 3008

TRICONEX 3625C1

TRICONEX 3503E

TRICONEX 3700A

TRICONEX 3625

TRICONEX 4200

TRICONEX RXM4200-3

TRICONEX 8310

TRICONEX 3626X

TRICONEX MP3101S2

TRICONEX PLM3900N

TRICONEX 8310

Triconex IMFF4703x

TRICONEX 3351S2

Triconex 3603E

Triconex Mar-01

TRICONEX 3401S

TRICONEX 3401S2

TRICONEX 3009

TRICONEX RXM4201

Triconex 3501T

TRICONEX 3503E

TRICONEX 3503E

TRICONEX 3504Е

Triconex 3604E

TRICONEX 3623T

Triconex 3636R

TRICONEX 3704E

TRICONEX 3704Е

TRICONEX 3723X

TRICONEX 3805E

TRICONEX 3805E

TRICONEX 3805E

Triconex 3805E

Triconex 3806E

TRICONEX 8310N2

Triconex 4210

Triconex 4211

TRICONEX 9566-810

TRICONEX 3351S2

TRICONEX 3511

TRICONEX 3664

TRICONEX 3625C1

TRICONEX 3008

Triconex 3607E

TRICONEX 3604E

TRICONEX 3009

TRICONEX 3624

TRICONEX RXM4201

TRICONEX 8310

TRICONEX 4351B

TRICONEX 4351B

TRICONEX 4351B

TRICONEX CIM3211S2

TRICONEX DI3301S2

TRICONEX A03481S2

TRICONEX 3805H

TRICONEX 3506X

TRICONEX 3626X

TRICONEX 4355X

TRICONEX 7400247-020

Triconex 8311

WhatsApp: +86 16626708626

WhatsApp: +86 16626708626 Email: 3772179818@qq.com

Email: 3772179818@qq.com Phone: +86 16626708626

Phone: +86 16626708626