Description

In the intricate web of safety instrumented systems (SIS), where seamless data exchange between controllers and external networks can prevent cascading failures or overlooked process anomalies, engineers often navigate bottlenecks like protocol mismatches, latency in real-time polling, or vulnerability to network-induced faults in hybrid automation landscapes. The Triconex CIM3211S2 rises to this challenge as a high-performance communication interface module, crafted to forge reliable bridges in Triconex TMR environments. Envision a petrochemical distillation unit where the SIS must sync safety data with a DCS for coordinated shutdowns—if communication drops or garbles even a single variable, it could delay responses to pressure spikes, risking equipment integrity or regulatory non-compliance. This module stands out as vital in such process control arenas, where high reliability for I/O signals across protocols underpins operational continuity and fault isolation.

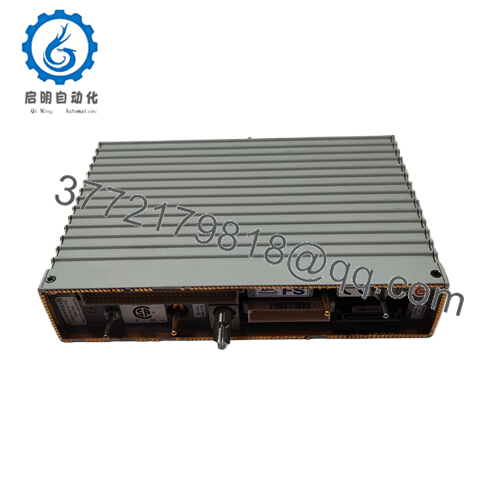

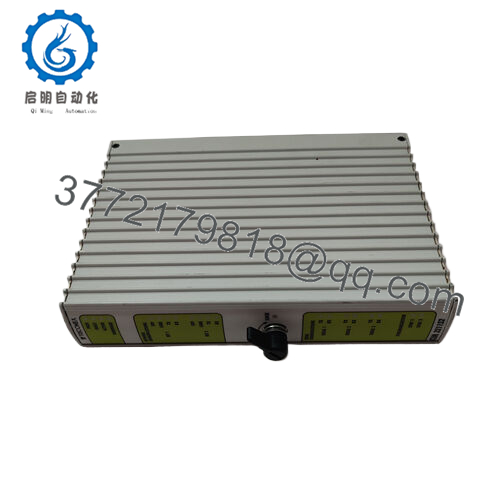

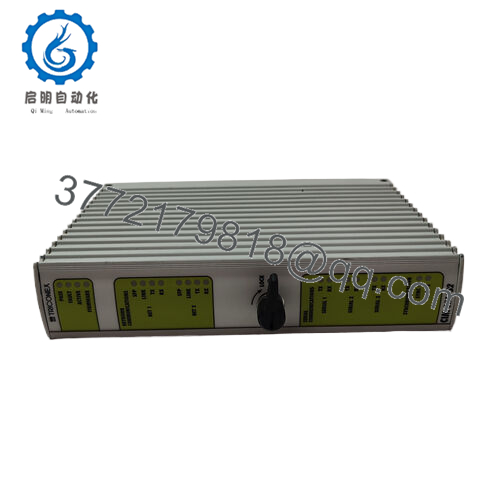

- CIM3211S2

- CIM3211S2

The Triconex CIM3211S2 addresses these pain points by enabling deterministic data flows, supporting Modbus over Ethernet for effortless integration with SCADA or HMI overlays without custom gateways. It’s a cornerstone for scenarios demanding modular expansion, like fire-and-gas monitoring or ESD loops, where its isolation safeguards against transients that could compromise TMR voting. In electrically noisy plants with diverse legacy systems, it averts common issues such as packet loss or unauthorized access, streamlining diagnostics and cutting integration timelines. Keywords like “industrial automation,” “process control,” “I/O signal,” and “high reliability” define its domain—the Triconex CIM3211S2 empowers teams to unify disparate networks, fostering resilient architectures that prioritize safety without stifling efficiency in SIL 3-certified operations.

At the heart of the Triconex TMR stack, the Triconex CIM3211S2 slots into the I/O chassis alongside main processors like the 3009, serving as the gateway for outbound and inbound traffic to external devices via its Ethernet ports and serial interfaces. It translates TMR-voted commands into protocol-compliant packets—handling Modbus TCP requests for variable reads or writes—while buffering data to mask minor network hiccups, ensuring the controller remains oblivious to peripheral disruptions. This positioning extends the backplane’s reach, linking field I/O modules to higher-level systems like DeltaV or Wonderware, with redundant paths for failover that maintain sub-10 ms latency in polled exchanges.

The module’s diagnostics include link status monitoring and error counters relayed via TriBus, integrable with protocols like OPC UA for advanced analytics, allowing the host to detect cabling faults or bandwidth overloads proactively. In a typical gas compressor setup, the Triconex CIM3211S2 might ferry interlock statuses from digital inputs to a remote HMI, applying checksums to validate integrity and triggering alerts on discrepancies—all while adhering to TMR synchronization for unanimous outputs. Its user-accessible configuration through TriStation software simplifies protocol mapping, and support for VLAN tagging enhances security in segmented networks. Rather than dictating rigid setups, this design adapts to evolving architectures, reducing the overhead of multi-vendor interoperability and keeping the focus on core safety logic in the broader automation ecosystem.

| Specification | Details |

|---|---|

| Model Number | CIM3211S2 |

| Brand | Triconex (Schneider Electric) |

| Type | Communication Interface Module |

| Input Voltage | 24 VDC (18–32 VDC range) |

| Operating Temp Range | -40 to +70°C |

| Mounting Style | Chassis-mounted (Tricon v11+) |

| Dimensions | 6.5″ x 4″ x 1.5″ (165mm x 102mm x 38mm) |

| Weight | 0.7 kg |

| Interface/Bus | Ethernet (RJ45), RS-485, TriBus |

| Compliance | SIL 3, IEC 61508, CE, ATEX |

| Supported Protocols | Modbus TCP/RTU, Ethernet/IP, OPC UA |

| Typical Power Draw | 6W (at 24 VDC) |

Embracing the Triconex CIM3211S2 unlocks a layer of connectivity that safeguards long-term performance, as its 1500 VAC isolation fortifies against ground shifts or surges that might otherwise corrupt data streams in volatile grids. Operationally, this equates to flawless polling of safety parameters—like valve positions or alarm thresholds—without the jitter that plagues unbuffered links, enabling operators to trust real-time dashboards for proactive interventions and averting the downtime from resyncs after glitches. Tuned for TMR environments, it delivers 100% diagnostic coverage, spotting protocol errors early to sustain 99.999% availability in loops where delays could amplify hazards.

The module’s protocol versatility further trims engineering overhead, letting teams layer in Ethernet/IP for CIP motion data alongside Modbus without parallel hardware, which accelerates commissioning in brownfield upgrades. Maintenance gains efficiency through front-panel LEDs for port activity and embedded counters that feed into asset management tools, pinpointing issues like cable attenuation before they escalate—ideal for distributed sites where on-site visits strain budgets. By embedding security features like encrypted sessions, the Triconex CIM3211S2 not only complies with cybersecurity mandates but also minimizes breach vectors, empowering facilities to evolve their automation footprint with confidence, where communication becomes a strength rather than a silent risk.

In oil and gas platforms, the Triconex CIM3211S2 links SIS controllers to subsea sensors via Modbus RTU over long-haul RS-485, enduring saline corrosion and power fluctuations to uphold high reliability in process control, ensuring critical system uptime for blowout preventer commands amid remote, high-pressure operations. Its low-latency Ethernet fallback handles surge data from wellheads without bottlenecks.

Chemical manufacturing deploys the Triconex CIM3211S2 for batch reactor oversight, interfacing with legacy PLCs through OPC UA to synchronize inhibitor feeds—thriving in humid, EMI-dense halls where its isolation prevents false interlocks, supporting fast data cycles for yield optimization in volatile reaction environments.

Power utilities integrate the Triconex CIM3211S2 in substation protection relays, bridging TMR logic to SCADA via Ethernet/IP for grid event logging; its SIL 3 robustness ensures process control integrity under lightning-prone conditions, maintaining blackout prevention through unwavering signal fidelity.

Triconex 4351B – Enhanced communication module for expanded protocol support in TMR networks.

Triconex MA2211-100 – Redundant high-speed serial interface for legacy RS-232/485 integrations.

Triconex 3009 – Main processor companion for advanced TMR voting with CIM3211S2 traffic.

Triconex 9760-210 – Termination panel add-on for field cabling to communication ports.

Triconex 8310N2 – Power entry module for isolated feeds to CIM3211S2 setups.

Triconex 3604E – Digital output module to pair for bidirectional control via the interface.

Triconex 3211S2 – Analog conditioner variant for signal prep before CIM3211S2 transmission.

Before commissioning the Triconex CIM3211S2, align its firmware with the chassis host—v11 or higher via TriStation—to preempt protocol handshake failures, and map Ethernet IPs statically to avoid DHCP conflicts in segmented VLANs. Probe isolation at 1500 VAC with a dielectric tester pre-install, confirming no shorts, and cap unused ports to block ingress; verify power ripple under 100 mV on 24 VDC lines to sustain packet integrity. In ATEX zones, pair with certified enclosures, and baseline network throughput with a packet analyzer for <5% loss.

Upkeep for the Triconex CIM3211S2 revolves around quarterly port inspections—clean RJ45 contacts with ESD-safe tools and torque terminals to 0.4 Nm against vibration creep—while polling error logs monthly through TriStation for trends like CRC mismatches, addressing via cable swaps if exceeding 0.1%. Biannually, stress-test redundancy by simulating link drops to confirm TMR failover under 50 ms, and in dusty venues, vacuum vents gently to preserve airflow. Annual SIL audits include protocol conformance checks per IEC 61508, but keep them targeted: no full disassembly, just firmware patches from Schneider’s portal. This regimen, practical and metrics-driven, preserves the module’s edge without derailing schedules.

WhatsApp: +86 16626708626

WhatsApp: +86 16626708626 Email:

Email:  Phone: +86 16626708626

Phone: +86 16626708626