Description

Real-World Use & Application Scenarios

In mission-critical industrial automation sectors, the TRICONEX 9566-810F plays a vital role in ensuring operational safety and signal integrity. Used extensively in industries like oil and gas refining, petrochemicals, power plants, and heavy manufacturing, this digital input termination panel supports control systems requiring secure and dependable field signal interfacing. It is especially applicable in safety instrumented systems (SIS) where quick and accurate status detection from field devices can prevent hazardous events, minimizing downtime and protecting assets and personnel.

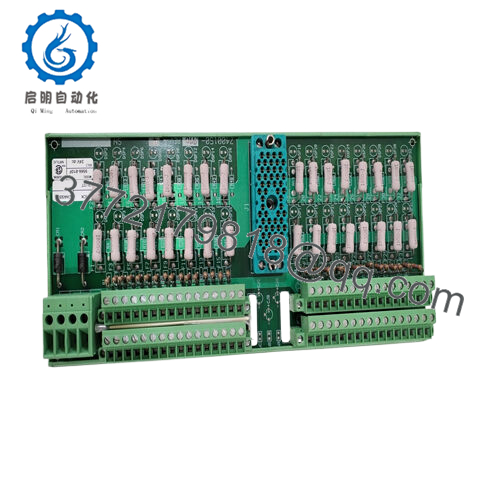

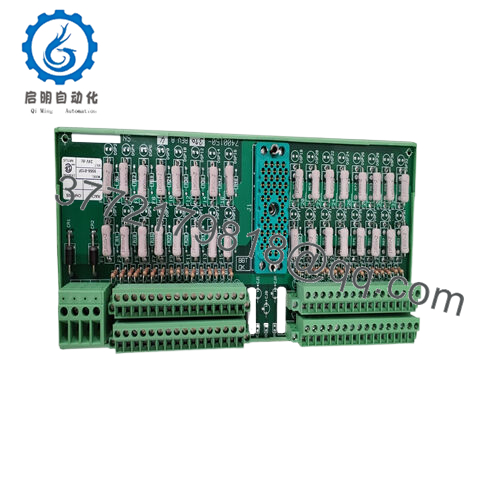

The TRICONEX 9566-810F is engineered to manage digital input signals from a wide range of field devices operating at 24 or 48 VDC, including switches, relays, and sensors. It provides 32 input points per panel, each protected by built-in current-limiting resistors, safeguarding the connected control modules against electrical faults or excessive currents. Commoned power terminals simplify wiring and enhance system reliability. This panel addresses challenges like electrical noise suppression and fault isolation, making it ideal for integrating into the TRICONEX TMR architecture, which emphasizes redundancy and fault tolerance for mission-critical safety control.

Product Introduction & Positioning

The TRICONEX 9566-810F is a digital input termination panel, a key interface component within the TRICONEX family of safety instrumented systems. Specifically designed for compatibility with 24/48 VDC digital input modules used in TRICONEX v9–v10 systems, it serves as the intermediary between field devices and control system logic. Positioned as a foundational hardware element, it ensures the reliable aggregation, protection, and transmission of discrete input signals into the TRICONEX control platform.

Its design allows seamless integration into existing TRICONEX frameworks, supporting high-density input configurations and maintaining signal clarity with current-limiting and opto-isolation features. For engineers and system integrators, the 9566-810F offers a straightforward solution to complicated signal wiring needs while enhancing system resiliency. Its role in simplifying wiring architecture and providing diagnostic feedback contributes to lower maintenance overhead and improved system availability.

- 9566-810F

Key Technical Features & Functional Benefits

The TRICONEX 9566-810F boasts 32 input points per panel, equipped with 180 ohm built-in current-limiting resistors to protect modules and field wiring from overcurrent conditions. Designed for 24 or 48 VDC operations, it streamlines field wiring by incorporating commoned power terminals (PWR+ and PWR–), effectively reducing complexity while improving fault isolation. The panel is optimized to operate reliably within an industrial temperature range from 0 to 60°C, suitable for typical control room or clean panel environments.

Its inbuilt opto-isolators provide threshold detection at each input point, ensuring noise immunity and accurate status transmission to the input multiplexers within the TRICONEX controller. Diagnostic LEDs and test relays enable maintenance crews to verify integrity without disrupting operations, which is crucial for minimizing downtime in safety applications. The durable mechanical design supports standard TRICONEX rack mounting with specified torque ratings for wiring terminals to maintain long-term stable contacts.

Compatibility with TRICONEX digital input modules and adherence to safety standards ensures this termination panel supports system architectures up to SIL 3. Its rugged construction and high-density interface make it indispensable for integrators designing safety systems within complex safety instrumented architectures requiring fault-tolerant, redundant signal processing.

Detailed Technical Specifications

| Parameter | Value |

|---|---|

| Model | 9566-810F |

| Brand | TRICONEX |

| Product Type | Digital Input Termination Panel |

| Input Points | 32 input points per panel |

| Input Voltage Range | 24/48 VDC |

| Current Limiting Resistor | 180 ohms per input point |

| Power Terminals | Commoned PWR+ and PWR– |

| Operating Temperature | 0 to 60°C |

| Storage Temperature | -40 to 85°C |

| Humidity (non-condensing) | 0 to 95% |

| Mounting | Rack-mounted in TRICONEX chassis |

| Terminal Torque Specification | 4.425-5.310 lbf-in (0.5-0.6 Nm) |

| Diagnostics | Opto-isolated test relays, LEDs |

Related Modules or Compatible Units

TRICONEX 3504E – 24/48 VDC digital input module compatible with the 9566-810F panel for dense signal handling.

TRICONEX 3625 – Digital output module for complementary output control in TRICONEX systems.

TRICONEX 8312 – Redundant power supply module supporting uninterrupted power delivery.

TRICONEX 9561-810 – Analog input module compatible with TRICONEX v9–v10 systems.

TRICONEX 9662-810 – Communication interface module for TRICONEX network expansion.

TRICONEX 4351B – Main processor module integrating input signals for safety logic processing.

Installation Notes & Maintenance Best Practices

When installing the 9566-810F, ensure the TRICONEX rack and cabinet environment meet the temperature specifications of 0 to 60°C and provide adequate ventilation to prevent overheating. Carefully plan field wiring to leverage the commoned power terminals, reducing wiring complexity while ensuring proper grounding and shielding to minimize electrical noise. Terminal block torque specifications must be followed meticulously during installation to prevent loosening and intermittent contact that could cause signal faults.

Routine maintenance should include regular inspection of wiring terminals and checking LED indicators for signs of faults or blown fuses. Use the built-in test relays to periodically verify input channel integrity without disrupting system operation. Maintain cleanliness to prevent dust or moisture accumulation, which could affect connectivity and panel reliability. Firmware and diagnostic updates should be applied as recommended by TRICONEX to ensure compliance with evolving safety standards and system optimization.

WhatsApp: +86 16626708626

WhatsApp: +86 16626708626 Email:

Email:  Phone: +86 16626708626

Phone: +86 16626708626